12

10 Faults, causes and remedies

Faults, particularly those affecting the pumps or

the control system, must be remedied by Wilo’s

customer service or a specialist company

NOTICE!

The general safety instructions must be observed

during any maintenance or repair work! The instal-

lation and operating instructions of the pumps and

the control device must be observed!

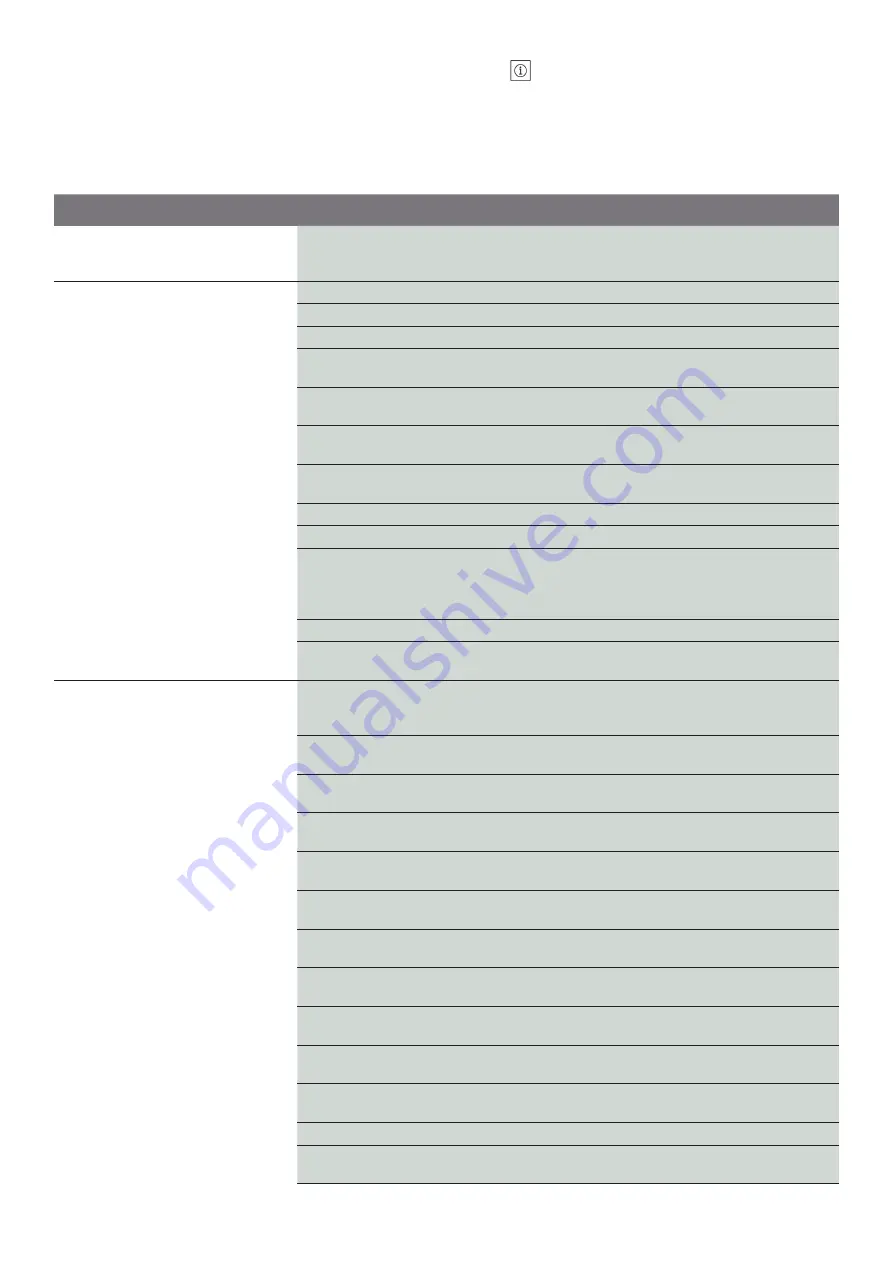

Fault

Cause

Remedy

Display on the control device incorrect

Make use of the information from the installa-

tion and operating instructions for

the control device

Pump(s) do(es) not start

No mains voltage

Check the fuses, cables and connections

Main switch “OFF”

Activate the main switch

Water level in break tank too low, i.e.

Check the break tank’s inlet valve / supply line

Low-water level reached

Check the inlet pressure and the level in the

break tank

Low water level indicated

Check and, if necessary, replace the low water

switch

Low water switch defective

Check installation and setting and correct as

required

Shut-off device closed at pressure sensor

Check and open the shut-off valve if neces-

sary

Start-up pressure set too high

Check the setting and correct it if necessary

Fuse defective

Check fuses and replace if necessary

Motor protection has triggered

Check the default values against the pump or

motor data, measure the current values and

correct the setting if necessary. Check the

motor for defects and replace if necessary

Contactor defective

Check it and replace it if necessary

Turn-to-turn fault in the motor

Check, if necessary replace motor or have it

repaired

Pump(s) do not switch off

Major fluctuations of the inlet pressure

Check the inlet pressure and take measures to

stabilise the inlet pressure if necessary (e.g.

pressure reducers)

Inlet pipe clogged or shut off

Check the inlet pipe and remove the clogging

or open the shut-off valve if necessary

Nominal diameter of the inlet pipe too

small

Check the inlet pipe and increase the cross

section of the inlet pipe if necessary

Inlet pipe installed incorrectly

Check the inlet pipe and change the pipe

routing if necessary

Air in the inlet

Check and shut off the piping and vent the

pumps if necessary

Impellers clogged

Check the pump and replace it or have it

repaired if necessary

Non-return valve leaking

Check and replace the seal or non-return

valve if necessary

Non-return valve clogged

Check and remove the clogging or replace the

non-return valve if necessary

Gate valve in the system closed or not

sufficiently open

Check and open the shut-off valve completely

if necessary

Flow rate too high

Check the pump data and default values and

correct if necessary

Shut-off device closed at pressure sensor

Check and open the shut-off valve if neces-

sary

Switch-off pressure set too high

Check the setting and correct it if necessary

Incorrect direction of rotation of the

motors

Check direction of rotation and correct by

changing over phases if necessary

Summary of Contents for ISAR MODH1 Series

Page 16: ...16 Fig 1 Fig 1b Fig 1c...

Page 21: ...21 NOTES...