13

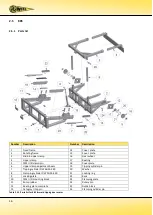

2.3.2 Commissioning the K75A and K75B box rotators

Type K75A and K75B forward tipping box rotators can be supplied with the necessary fitting components or

without (bare machine). In the former case users must make their own arrangements for the attachment. In

the latter case, the type of machine to which the K75A or K75B is to be fitted should be specified. Where

available fitting can take place in the factory, and the normal guarantee provisions will apply.

1.

Bear in mind that with an electrically controlled switching valve, 1 double action hydraulic connection must

be present on the lifting vehicle, and with a 4-hose connection, 2 double action hydraulic connections.

Connection of hydraulic hoses

Depending on the model, the following hydraulic hoses are connected:

a)

Electrically controlled reversing valve

Connect the hydraulic supply/discharge hoses to the dual-action connection on the fork carrier.

Install the supplied switch so that the machine driver is able to operate it from his driving position and

cannot confuse it with other controls. For a safe working environment, avoid situations such as inadvertently

starting the machine or not being able to control it.

Keep an eye on the correct voltage of the lifting device and the valve. The voltage is shown on the coil.

Connect a twin core cable in accordance with the circuit diagram. Include a warning light, fuse and/or plug

socket in the circuit if required.

b)

Four-hose connection

Connect the two pairs of hydraulic supply/discharge hoses to the dual-action connection on the fork carrier.

ATTENTION:

WIFO-Anema B.V. can accept no liability for the construction and mounting of fitting equipment

attached by users themselves.