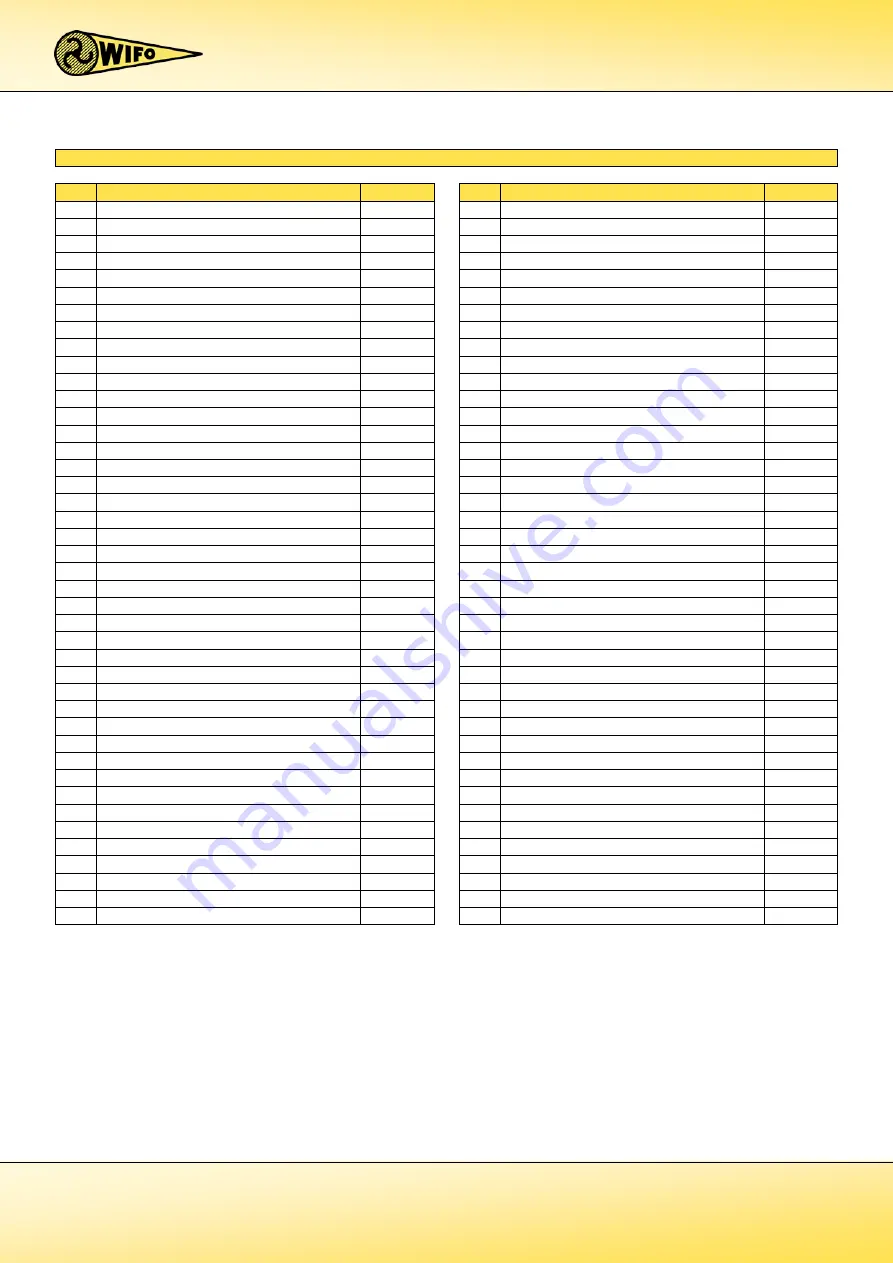

14

Type: SK55A/SK55C

Nr. Onderdeel:

Artikelnr.:

Nr. Onderdeel:

Artikelnr.:

1

Back plate K55A

-

39

Gas spring folding fork

-

Back plate K55C

-

40

Tensioner gas spring

-

2

Clamping strip (t.b.v. SK55A)

-

41

Nut M20

-

Clamping strip 50x25-L100 (t.b.v. SK55C)

-

42

Washer M20

-

3

Bolt M16x50

-

43

Locknut M20

-

4

Spring washer M16

-

44

Lockpin folding fork

-

5

Bolt M12x60

-

45

Eccentric lockpin

-

6

Nut M12

-

46

Compression spring Ø35x3-L40

-

7

Bolt M12x30

-

47

Bolt M10x45

-

8

Heico lock washer M12

-

48

Locknut M10

-

9

Bronze bearing Ø75x60,8-L90

-

49

Nameplate WIFO

-

10

Stripper Ø60x70x7/10

-

50

Rack shaft C45-M5-Ø60-L783

-

11

Pivot pin Ø125x172 (t.b.v. SK55A)

-

51

Rack block

-

Pivot pin Ø125x189 (t.b.v.SK55C)

-

52

Heico lock washer M30

-

12

Fork carrier SK55A

-

53

Bolt M30x80

-

Fork carrier SK55C

-

54

Flat nut M30

-

13

Gearwheel C45-M5-Z=60

4290114

55

Circlip internal Ø80

-

14

Tapered roller bearing 33018

429029

56

Stripper Ø60x70x7/10

-

15

Tapered roller bearing 33117

429030

57

Bronze bearing rack shaft Ø75x60,2-L70

-

16

Packing seal Ø145x125-L14 H9

429035

58

Rack section

-

17

Packing seal Ø145x125-L14 H9

429035

59

Rotating cylinder DW80-35-377

-

18

Locking plate Ø160-L25

4290073

60

Locknut M14

-

19

Grease nipple M8

-

61

Ball valve 3/8”2-weg

429062

20

Adjusting screw M12x40

-

62

Balancing valve 3/8”EW

429057

21

Nut M12

-

63

Adjusting screw M10x20

-

22

Spring washer M12

-

64

Hex sock bolt M8x16

-

23

Bolt M12x50

-

65

Grease nipple M8

-

24

Hex sock bolt M12x80 12.-

-

66

Washer Ø50x17-L8

-

25

Roll pin Ø14x90

-

67

Spring washer M16

-

26

Bolt M16x25

-

68

Bolt M16x40

-

27

Spring washer M16

-

69

Sideshift cylinder DW70-30-200

-

28

Fork positioner folding fork

-

70

Bolt M16x70

-

29

Pin folding fork Ø30-L201

-

71

Spring washer M16

-

30

Roll pin Ø10x60

72

Guiding section left

-

31

Fork folding fork

-

73

Guiding section right

-

32

Grease nipple M8

-

74

Guiding shaft Ø60-L810

-

33

Folding fork extention

-

75

Guiding shaft Ø60-L810

-

34

Compression spring Ø42x3,5-L40

-

76

Hydraulics mounting plate

-

35

Locking plate folding fork extention

-

77

Bolt M16x50

-

36

Body washer M10

-

78

Heico lock washer M16

-

37

Bolt M10x25

-

79

Bolt M10x30

-

38

Gas spring block

-

80

Washer M10

-

Table 2.3.1- Parts list for SK54A and SK55C

Summary of Contents for K55A

Page 2: ......

Page 12: ...10 2 2 K55A and K55C 2 2 1 Parts list Figure 2 2 1 Parts drawing for K55A and K55C...

Page 15: ...13 2 3 SK55A and SK55C 2 3 1 Parts list Figure 2 3 1 Parts drawing for SK55A and SK55C...

Page 22: ...20 Figure 3 3 1 Position of the tapered roller of K55A K55C SK55A and SK55C...

Page 23: ......