Page 40

Issue 5.2 – March 2016

8

Faulty Printing Quality

!

WARNING

Settings for the printing quality may only be done by trained service

personnel.

Upon touching the print head a risk of burns may be present with a

defective heating element (see chapter 4.3).

The following points must be checked before searching for further caus-

es of faults:

•

Is the charge electrode slit perfectly clean?

•

Are the deflector plates and basis unit perfectly clean?

•

Is modulation/drop separation set correctly?

•

Is alignment of the ink jet in the charge electrode parallel/central?

•

Is system pressure set correctly (see chapter 6.2)?

•

Does the ink jet hit the gutter tube?

•

Correct ink density?

IMPORTANT

See also the enclosed CD for further information about printing quality

faults.

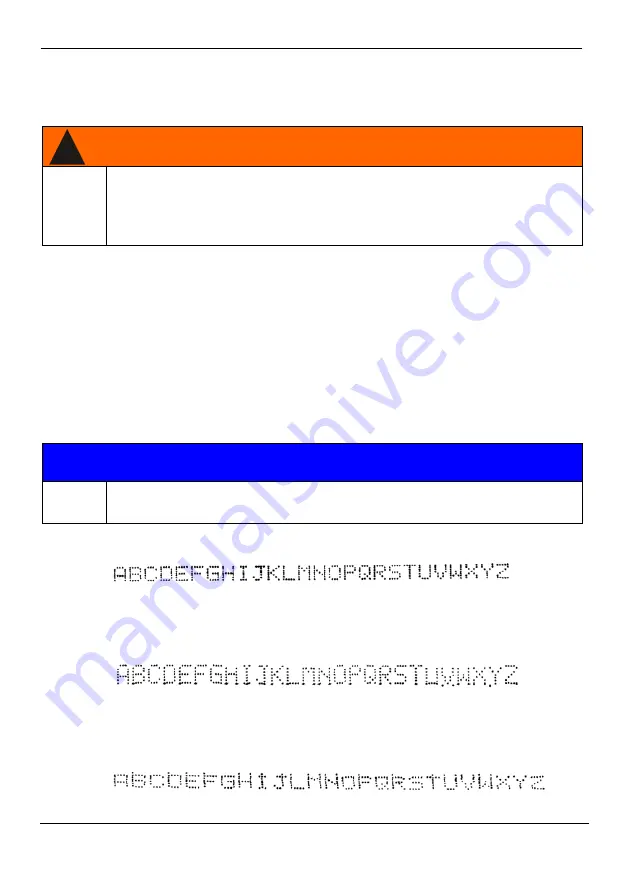

Correctly set printing quality:

Omitted or double drops. The horizontal and vertical drops do not form a

line.

System pressure too low. Modulation not adjusted correctly.

No straight lines to characters. The vertical drops overlap the horizontal

drops.

System pressure too high. Modulation not adjusted correctly.

Summary of Contents for Komax ims 295 BC

Page 1: ...ims 295 Series Operating Manual ...

Page 2: ...Page 2 Issue 5 2 March 2016 Notes ...

Page 23: ...Issue 5 2 March 2016 Page 23 12 mm For mounting the protections proceed in reverse order ...

Page 25: ...Issue 5 2 March 2016 Page 25 ...

Page 50: ...Page 50 Issue 5 2 March 2016 12 EC Declaration of Conformity ...