9

8

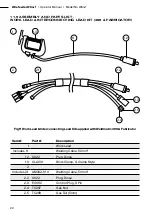

Wirefeeder W64-1 | Operator Manual | Model No W64-1

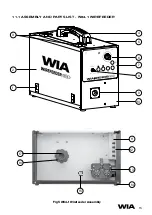

1 Power on Indicator

This indicator is illuminated when

wirefeeder is connected to a power source

and the power source is switched on.

2 Arc start

This control can be set to modify arc

starting conditions. For many applications

the control can be set at the mid point.

Rotating the knob towards ‘FAST’ will

provide faster wire acceleration at arc

start giving quicker starts, suitable for

applications such as rapid tack welding.

Rotating the knob towards ‘SOFT’ will

slow wire acceleration, providing a softer

start suitable for larger diameter and

aluminium wires.

3 Wire Speed Control

This control sets the speed of the wire

drive motor within the range of 0 - 172 RPM,

equivalent to 0 - 20 metres per minute of

welding electrode wire. Rotate the control

clockwise to increase the feed speed.

This control is used in conjunction with the

Wire Speed Range Select Switch. Switch to

low for slower (0-10 metres/min wirespeed

control and switch to high for higher (8-20

metres/min) wire speeds.

4 Wire Speed Range Indicator Light

This indicator is illuminated when speed

range is set to High speed range (8-20

metres/min).

5 Wire Speed Range Select Switch

Press to change from Low wire speed range

to High wire speed range.

6 Purge Button

Press to open the gas solenoid valve without

energising the welding power source.

4 CONTROLS

3 SPECIFICATIONS

Wirefeeder

Supply Voltage

32 volts AC, (from welding power source)

Rated Supply Current

5 Amps

Pre-gas Range

0 - 2 seconds

Post-gas Range

0 - 10 seconds

Start Speed

Normal or Creep (switchable)

Spool Sizes

5 kg, 15 kg

Wirespeed Range

0 - 172 RPM: 0 - 20 Metres per min

(0 - 10 Metres per min Low Speed Range,

8 - 20 Metres per min High Speed Range)

Wire Size Range

0.6mm - 1.6mm diameter