1INSTALLATION

The dryer is designed for installation using a flexible gas

connection with tubing in accordance with B.S.669.

Ensure that the supply gas sizing is adequate.

When installing, position the appliance so that the plug is

accessible.

An electric supply cord with moulded-on 13 Amp.plug is

fitted at the back of the dryer.The length is 1.5 m.(5ft.).

If there are any other appliances that are relatively high

rated (eg a central heating boiler)fed from the same gas

supply branch, it is advisable to perform the verification of

inlet pressure with both appliances in operation.

Prior to installation, check that the local distribution

conditions, nature of gas and pressure and adjustment of

the dryer are compatible.

2 AIR SUPPLY

The tumble dryer shall be installed in a room or internal

space having an openable window, or equivalent.The

customer must be advised that this must be kept open

during use.

Purpose provided ventilation of 100cm² shall also be

provided where the room volume is less than 3.7m 3/kw

of appliance rated heat input.

Additional guidance on the provision of air supply may be

obtained from BS5440 parts 1 and 2 and BS 7624:2004

If the dryer is to be installed in a room or internal space

that already contains one or more fuel burning

appliances, the ventilation requirements above, together

with any additional requirements of BS5440-2:2009, 5,5

shall be applied.

3 POSITION

The dryer must not be installed in a bedroom, bathroom

or shower room.

Great care is required in the location of the dryer in

premises where concentrations of flammable vapours

may accumulate, e.g.commercial garages and associated

workshops.

The dryer can be placed against a wall, other appliances,

kitchen furniture and similar surfaces.

4 VENTING

The dryer must be fitted with an exhaust vent hose and

the end either hung out of a window or fitted to a wall/

window vent connection.

Note:

Do not obstruct or add a mesh to the vent hose

outlet during use and ensure that it cannot be blocked or

bent sharply which obstructs the air flow.

It is recommended that the interior of the hose be

periodically inspected and cleaned if necessary.

PERMANENT VENTING

Accessory wall/window vent kit CL005 is available:

See illustration for necessary hole through wall.Dim A=

200mm and Dim B= 100mm for direct alignment.

Note DimBmay be increased to 200mm to facilitate easier

drilling if required.

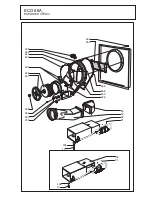

5 POSITION OF DRYER AND CONNECTIONS

The illustration shows the minimum space required by the

dryer and the position of the gas wall connector.It is not

acceptable to use a forward facing mounting plate because

of the space limitation.The sideways facing assembly must

be used and this should be fitted so that the flexible hose

hangs down from the bayonet connector.

A 13 Amp socket must be provided within a distance of 1.4

m (55 in.) of the cable entry into the dryer.The socket must

have an efficient earth connection.

If the dryer is to stand on a surface above the floor or on

top of a washing machine (using the Stacking Kit) then the

750 mm dimension is measured above the supporting

surface.

If the dryer is installed under a worktop there must be a

minimum gap of 15 mm between the top of the dryer and

the underside of the worktop to allow for ventilation.

If it is intended to move the dryer regularly for use then the

Restraining Kit must be fitted to prevent possible damage

to the gas connection.

We also recommend the fitting of a restraining kit to any

dryer which is stacked.

If using accessories:

Wall/Window Vent Kit

Stacking Kit

Restraining Kit

See separate fitting instructions included with each Kit.

INSTALLATION

4

Summary of Contents for eco 86A

Page 8: ......

Page 9: ......

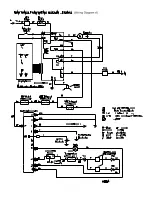

Page 10: ... 232 352 211 552 235 372 213 377 233 353 218 217 219 249 ...

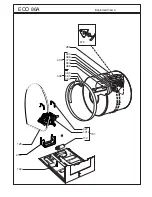

Page 13: ...ECO 86A Exploded View 4 466 477 444 467 465 463 468 464 438 439 266 270 ...

Page 18: ......

Page 19: ......

Page 20: ...Manufactured By Crosslee plc Halifax Road Halifax W Yorks HX3 8DE 4213 194 05463 ...