6. OPERATIONAL CHECK

6.1 Remove the pressure test point screw from the gas

tee connection at the back of the dryer and connect

a gas pressure gauge.

6.2 Check that the dryer control is in the 'off' position, and

that the heat switch is set to 'high'.

Remove anything from inside the drum, check that

the lint filter is fitted, shut the dryer door.

6.3 Turn on the gas, push the electric plug into the socket

and switch on the electricity supply.

6.4 Select program 9 (Timed). Check for ignition.If the gas

fails to remain lit then repeatedly open and close the

door, push the start switch and run the machine for

periods of at least 30 seconds until the air is

removed from the system and burning is continuous.

Note that gas is not lit when the drum is turning anti-

clockwise.

The flame recognition system will only

operate if the electric supply is polarity correct - live

is live and neutral is neutral.

6.5 With the gas burning ensure that the pressure is as

detailed in the Technical Data.Turn off and replace

the pressure test point screw.Check for soundness.

6.6 Switch on again and re-start so that the gas is

burning.Disconnect the flexible gas hose and check

that the solenoids can be heard to close.After 30

seconds turn on the gas and check that there is no

re-ignition.Switch the machine off and on again and

check for re-ignition.

6.7 Check that the operation of the machine does not

cause spillage of products of combustion from any

open flued gas appliance in the same room, or from

appliances in adjoining rooms, e.g.a gas fire or

central heating boiler.

6.8 In the event of an electrical fault after installation of

the appliance, preliminary electrical system checks

must be carried out (i.e.earth continuity, polarity and

resistance to earth).

6.9

IMPORTANT INFORMATION RE-FUNCTIONING

OF THE FULL SEQUENCE FLAME CONTROL

BOX.

THE FULL SEQUENCE FLAME CONTROL BOX

ON THIS APPLIANCE REQUIRES A 6-12 SECOND

RE-SET PERIOD FOLLOWING EACH

INTERRUPTION OF INPUT VOLTAGE.

6 SECONDS DELAY IS REQUIRED BETWEEN

EACH ATTEMPT TO RESTART THE APPLIANCE

FOLLOWING SWITCHING IT OFF, OR AFTER

OPENING THE DOOR.

THE CONTROL BOX WILL ONLY

WORK CORRECTLY WHEN THE ELECTRIC SUPPLY

TO THE DRYER HAS CORRECT POLARITY - LIVE IS

LIVE AND NEUTRAL IS NEUTRAL

7 AIRFLOW

It is most important that airflow to the plinth is not

restricted.

8 MAINTENANCE

This appliance does not require an annual service

unless it is required as part of a landlord's gas

safety certificate.

If you do have any maintenance activity carried out,

it should be carried out by a competent person (i.e.

registered Engineer).

9 STACKING

Instructions for stacking, if required, are supplied

with the stacking kit.

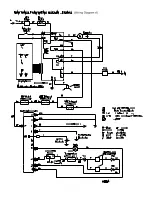

PROGRAMME

The electronic control measures dryness by the electrical

resistance method and operates relays to:a) energise

the drive motor, in foward and reverse rotation and b)

energise the full sequence flame controller.

The electronic controller determines when the selected

dryness level is reached, then turns off the heat source

and continues to rotate the drum for 12 minutes

"cool down", intermittent tumbling follows this until the

machine is unloaded - "anticrease" is indicated by an LED

(if selected).

The full sequence flame controller opens the tandem

solenoid gas valves after a delay time of about 8 seconds

and operates the pulsing spark ignition.If the flame is not

detected by the flame failure electrode within 10 seconds

then the valves are closed.The system must then be re-

set by switching the machine off and re-starting.

The heat selector switch provides options for either 60˚C,

or 50˚C, exhaust thermostat control.This results in the

burner cycling on and off giving Ionger than anticipated

drying times.Drying times vary depending on the weight

and size of the articles, type of fabric, dampness etc.

These thermostats turn off the heating towards the end of

the chosen cycle and so avoid waste of energy.The lower

temperature thermostat prevents delicate fabrics from

getting too hot with possible risk of damage.

An inlet thermostat is fitted in the ducting at the back of

the dryer.It may also operate under certain other

conditions of restriction of the air-flow, for example, an

overloaded drum or blocked lint filter.This thermostat

switches off the flame controller.This will result in the

burner cycling on and off giving longer than anticipated

drying times.

Should the thermostat fail there is an inlet cut-out

connected in circuit with the gas valves.After operation,

the cut-out can be re-set by switching OFF/ON the

mains supply for a periood, to restore heating but a service

call may be required to correct the initial fault.

The conditions of failure of the air flow, blow-back, or of

gas interruption are detected by the flame failure

electrode and the system is shut-down.

Both drum rotation and heater control are switched off

when the door is opened and switched on when the door

is reclosed, and the activate and start buttons pressed.

For programmes see chart on dryer control panel.

Note:

Do not allow fluff to accumulate around the dryer.

5

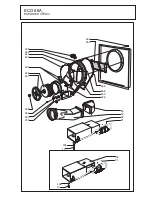

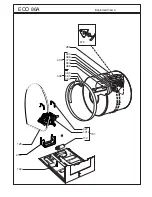

Summary of Contents for eco 86A

Page 8: ......

Page 9: ......

Page 10: ... 232 352 211 552 235 372 213 377 233 353 218 217 219 249 ...

Page 13: ...ECO 86A Exploded View 4 466 477 444 467 465 463 468 464 438 439 266 270 ...

Page 18: ......

Page 19: ......

Page 20: ...Manufactured By Crosslee plc Halifax Road Halifax W Yorks HX3 8DE 4213 194 05463 ...