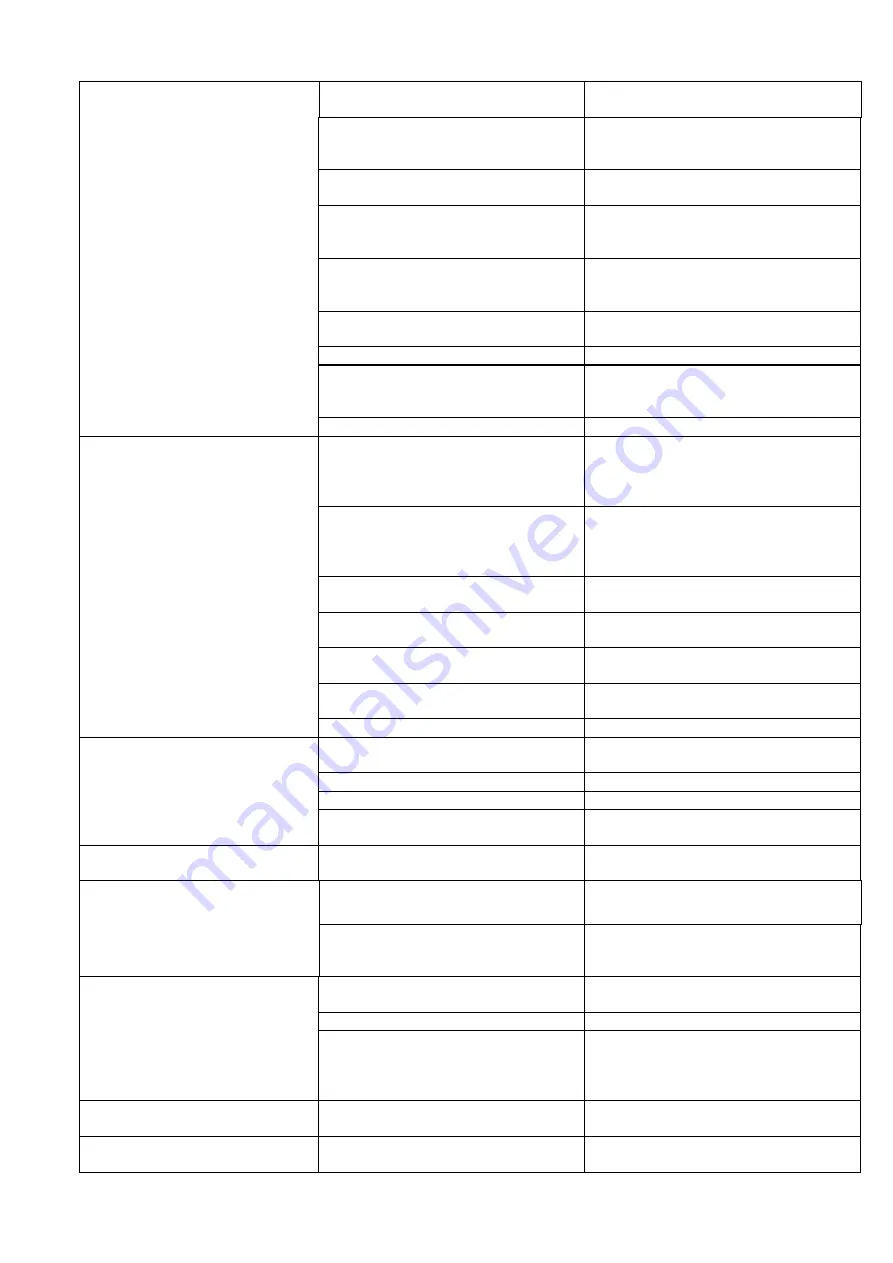

29

A) Faulty hot gas valve or wrongly

connected.

A) Verify and change if necessary.

B) Low water pressure.

B) Increase water pressure if possible.

(This can often be done by

removing flowmeter on faucet).

C) Fan pressostat or condensation

pressostat too low or faulty.

C) Adjust or replace.

D) Faulty condensation water inlet

valve (water cooled machines

without pressostatic)

D) Check and replace.

E) Faulty water pressostatic valve or

too open (water cooled machines

with this valve)

E) Adjust, repair or replace.

F) Room or water temperature below

7ºC.

F) Increase the defrost time.

G) Faulty timer or micros.

G) Check and replace if necessary.

H) Production time too long. The

cubes have flash outside the

mold.

H) Adjust by reducing time to the cycle

thermostat.

5) Ice cubes form correctly but

do not unstick.

I) Dirty water inlet filters.

I) Clean filters.

A) Blocked condenser or air access to

condenser.

A) Clean condenser; improve air

circulation by lifting machine from

floor and moving away from walls

and hot air sources .

B) In water-cooled machines:dirty

condenser, badly adjusted valve,

pressostat, faulty water inlet valve

or faulty pressostatic valve.

B) Clean condenser; check, adjust or

replace.

C) Faulty hot gas valve, doesn’t close

totaly.

C) Replace.

D) Faulty fan or pressostat, faulty

inlet cooling water valve.

D) Check fan and re-adjust pressostat

or replace.

E) Refrigerant charge too high or too

low.

E) Adjust.

F) Faulty water inlet valve: leaks and

does not close fully.

F) Check and replace.

6) Low ice production.

G) Inefficient compressor.

G) Replace.

A) Start of cycle thermostat adjusted

too low or faulty.

A) Adjust and/or replace.

B) Timer wheels do not run.

B) Tighten screws on timer.

C) Faulty timer motor.

C) Check and replace.

7) Ice cube are so large that

they stick together and form a

plate of ice

D) Faulty micros on timer or wrongly

connected.

D) Verify connections and/or change.

8) Ice cubes are too large.

A) Cycle thermostat adjusted too

high.

A) Adjust thermostat.

A) Cycle thermostat adjusted too

low.

A) Adjust thermostat.

9) Ice cubes are not completely

finished.

B) Low refrigerant charge.

B) Add refrigerant until there is frost

formation

5

cm

from

the

compressor at the end of the cycle.

A) Insufficient water in water pan;

unprimed pump.

A) Eliminate water leak.

B) Obstructed spray nozzles.

B) Clean nozzles.

10) Ice cubes are empty, rough

edges and very white.

C) The curtain strips does not fully

close and lose water.

C) Adjust the curtain strips or clean

the axle (it may has calcareous

impurities that avoid a smooth turn

of the strips).

11) Machine doesn’t stop even

when bin is full.

A) Faulty bin thermostat or wrongly

adjusted.

A) Adjust and/or replace.

12) Ice cubes melt in bin.

A) Obstruction in drains (inside the

machine or in premises).

A) Unblock.

Summary of Contents for ICE CUBES MAKERS Series

Page 1: ...ICE CUBES MAKERS Range SPRAY Technology ...

Page 8: ...8 ...

Page 9: ...9 SPECIFICATIONS Models NDP 20 NG DP 30 150 ...