4 - INSTALLATION INSTRUCTIONS

063_03

- GAS KITCHENS

9

· 22

03/2006

4.1 Safety rules

• Only a local gas utility technician is authorized to carry out gas

installations and connections. The statutory regulations (applied

in Germany VDE, Austria ÖVE, Switzerland SEV, etc.) and connec-

tion conditions performed by the gas utility must be strictly

observed.

• Connection to a power balance system for the installation in a

wall is provided for through a connection point. Adhere to cur-

rent local legal requirements for connection.

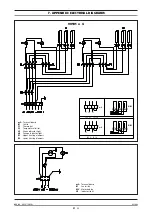

• Please note the electrical diagram! Compare the wiring diagram

number on the data plate of the appliance with the one shown

on the electrical diagram.

• Do not bend, crush or damage the cables against sharp corners.

• Lay the cables so as to avoid contact with extremely hot surfaces.

• The cable – which is totally sheathed – must be led inside the

appliance through the cable clamp and cable raceway installed

on the appliance.

• Ventilation system installation can be carried only by expert per-

sonnel.

• If the appliance is to be installed near walls, dividing walls,

kitchen equipment or decorative panelling, these should be in

non-inflammable material. If not, all appliances must be coated

with thermal-insulation fireproof material. Make sure that all fire

prevention standards and safety precautions are strictly adhered

to.

4.2 Structure, equipment and safety devices

of the unit

Robust steel frame, with 4 height adjustable feet.

18/10 chrome-nickel steel outer panelling.

4.2.1 Cooking zone

• Burner with stabilized flame.

• Gas cocks with safety and adjustable from maximum to minimum.

• Thermoelectric ignition safety.

•

Enamelled cast-iron pan supports.

• The bodies of the burners and the venturi tubes are made of cast

iron, while the lid is brass.

• 18/10 chrome-nickel steel cooking top.

• Knobs in thermosetting material.

4.2.2 Oven

The cooking chamber is made of stainless steel.

The runners for the pans are made of steel or chromed rod iron.

The pull-out grill i sin chromed rod-iron.

The door, with double wall and thermal insulation, is equipped with

an insulated handle and a hinge with balanced spring.

The insulation of the cooking chamber is fibreglass.

Gas version GN 2/1 and MAXI

The tubular burners are in chromed steel and are resistant to ther-

mal and mechanical stress.

Gas is supplied through a safety valve with a thermostat.

The main burner is switched on from a pilot burner with a fixed noz-

zle. It is also supplied with a thermoelectric ignition safety

with thermocouple connected to the pilot burner. The burner has a

piezo ignition.

The adjustment of the oven temperature, which can be varied

between 160 and 300° C, is made with the thermostat.

The bottom of the oven, in cast iron with reinforced ribs (for GN 2/1)

and steel (for MAXI), is in two pieces.

The smoke collector is in aluminised sheet metal and the protection

grill is in enamelled cast iron.

Gas version GN 1/1 ventilated

The tubular burners are in stainless steel and are resistant to ther-

mal and mechanical stress.

Gas is supplied through a safety valve with a thermostat and a safe-

ty thermocouple.

The ignition of the main burner takes place by means of an AT

transformer.

The adjustment of the oven temperature, which can be varied

between 160 and 300° C, is made with the thermostat.

The bottom of the oven is made of stainless steel.

The smoke collector is in aluminised sheet metal and the protection

grill is in enamelled cast iron.

Electric version GN 2/1

The heating elements are in the top (upper heat) and under the

bottom (lower heat).

Temperature adjustment between 50 and 300° C is made by a ther-

mostat connected to a tri-polar switch.

It is possible to turn on the upper and lower heating elements sepa-

rately or at the same time.

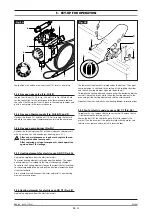

Indicator lights show when voltage is supplied to the appliance (see

Fig. 4A).

The cooking chamber is made of stainless steel.

The upper heating elements are visible (grill), while the lower ones

are covered by a sheet of stainless steel.

Electric version GN 1/1 ventilated

The heating elements are in the top (upper heat), under the bottom

(lower heat), and in the rear around the fan (convection).

The upper heating elements are visible (grill), while the lower ones

are covered by stainless steel panels.

Temperature adjustment between 50 and 300° C is made by a ther-

mostat connected to a switch.

The use of a 9-position commutator makes it possible to light the

heating elements separately or at the same time with ventilation or

in static mode.

The lighting of the heating elements is indicated by 2 indicator

lights (see fig. 4B).

4.2.3 Neutral cabinet

In model 90103, a neutral cabinet with a door alongside the oven is

standard.

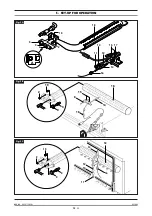

4.3 Assembly

4.3.1 Installation premises

The appliance should be installed in a well-ventilated room, and if

possible under a range hood (check current regulations).

The appliance can be installed on its own or with other similar

equipment.

If the appliance is to be installed near inflammable walls, a minimum

distance of 150 mm around the sides and back should be allowed.

If this distance cannot be obtained, take proper heat-protection

action such as fitting tiles or thermal radiation protection material

to the walls.

Before connecting the appliance to the gas supply, check on the

data plate that the appliance is suitable and type-tested for the

type of gas available.