Page 4

BLACK

WHITE

FUSE

10 AMP

+ 12 VOLTS

GROUND

CHASSIS

SUITABLE

(SP/ST)

SWITCH

12 VDC

To mount the PierceAlert™ in front of the

power supply on a 46” Lighbar.

1.

Disconnect the lightbar from its power source and wait at

least 15 minutes before proceeding any further

2.

Remove both endcaps from the extrusion.

3.

Slide all lenses and dividers out of the extrusion.

4.

Remove the Phillips-head screws or stand-offs

(depending on which of these your lightbar is equipped

with) from the power supply.

5.

Remove the power supply from the extrusion. Do not

disconnect the power supply from the lightbar harness

cables.

6.

Remove the two, inboard, Phillips-head screws from the

lightheads located on either side of the power supply

mounting area. Rotate the power supply/lighthead

mounting brackets and remove them from the

extrusion. If one of the power supply/lighthead

mounting brackets contains a fuse block, separate this

fuse block from the bracket before removing the bracket

from the extrusion.

7.

The next step is dependent upon how your lightbar is

equipped:

If your lightbar has a drip cover attached to the power

supply, remove the screws that secure this cover to the

power supply. Remove and discard the drip cover and

return the screws to their original position in the power

supply.

or

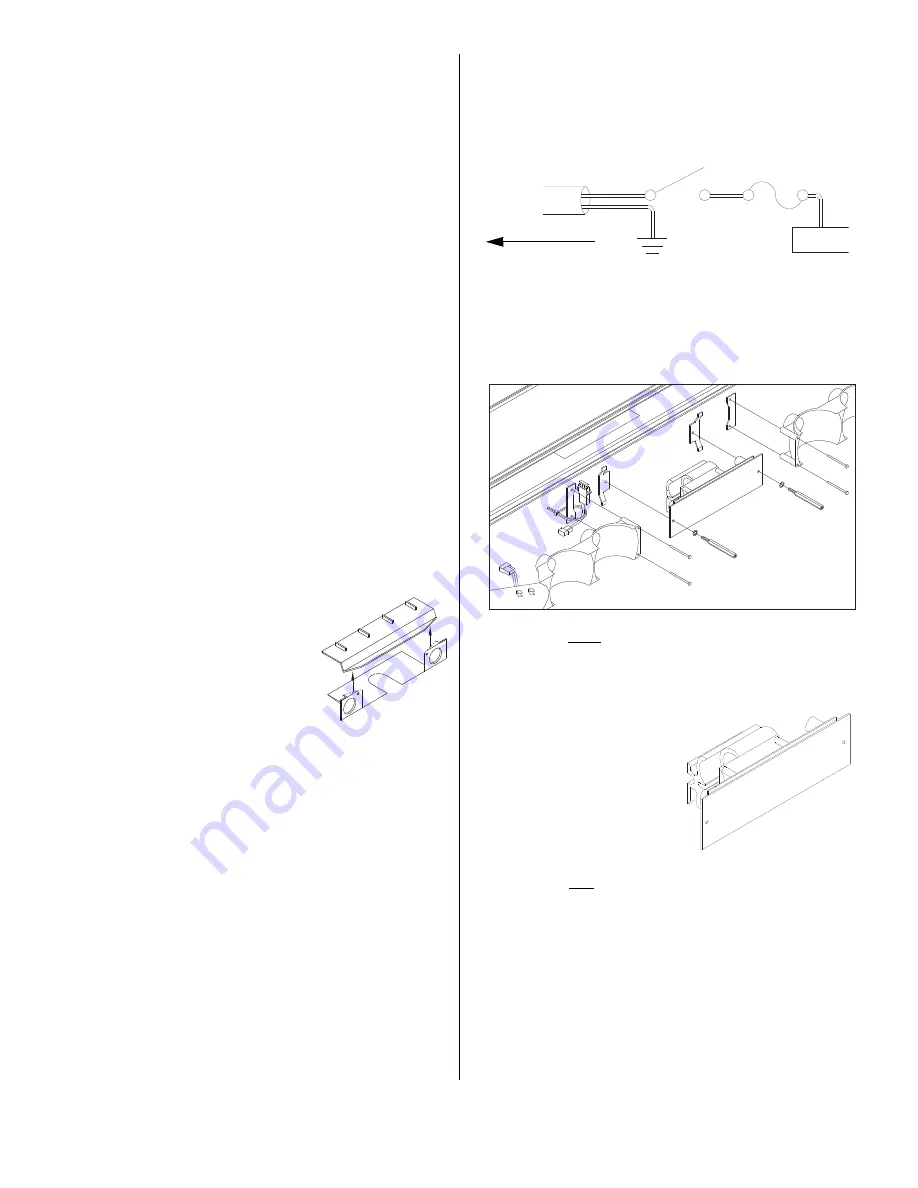

If your lightbar has a protective

housing fastened to the extrusion

behind the power supply, trim this

housing as shown in Fig. 1.

8. Remove the reflector assembly

that is located above the cable access hole in the

extrusion.

9.

If a matrix board is not located near the cable access

hole, skip to step 12.

10. Connect one end of the PierceAlert-to-Matrix™ harness

cable (supplied) into an available option port on the

matrix board.

11. Route this harness cable to the PierceAlert mounting

area.

12. If there are no available option ports on the matrix board,

or if there is no matrix board present, route the two-

conductor harness cable up through the cable access

hole, into the extrusion and directly to the PierceAlert

mounting location.

13. Route this two-conductor cable along the same path as

the existing input cable for your lightbar, and connect it to

either an existing switch-head or to a user supplied

switch. Refer to the wiring diagram for details.

Fig. 1

TO LIGHTBAR

Fig. 2

16. Using the supplied tie-wrap, secure the fuse block to the

new lighthead bracket (See Fig. 3).

17. Install the new lighthead brackets in the extrusion as

shown in Fig.3.

Note: Be sure to plug the fuse block

back into the wiring harness before continuing.

18. Install the metal (not plastic), recessed power supply

mounting brackets that are included in this kit. Be sure

that these are positioned in the power supply mounting

area.

19. Now examine the heat sink

on your power supply. If it is

the same as the heat sink

shown in Fig. 4, it must be

removed and replaced with

the heat sink included with

this kit. If the existing heat

sink is the same as the one

included with this kit, do not

replace it.

20. Using the long stand-offs and the internal-tooth lock

washers included with this kit (Fig. 3), remount the power

supply in the extrusion. Do not allow any harness wires

to be pinched between the power supply and the

extrusion!

21. Slide the lens spacer (included) into the bottom lens

channel of the extrusion. Position this spacer directly in

front of the power supply.

Fig. 3

14. Return the reflector to its mounting area in front of the

cable access hole and secure with the original screws.

15. Now secure the reflector (referenced in steps 9 & 10) to

its new mounting bracket with its original screws.

Fig. 4