1.8. 33-125-lA

CAS-8 OPERATING MECHANISM

DESCRIPTION

The Type CAS-8 Operating Mechanism is equipped

with single coil shunt trip, an exhaust valve with

magnetic pilot, a magnetically operated pilot valve

for the automatic intake (this pilot valve can also be

operated manually by means of a pushbutton on top

of the magnet valve), an automatic throttle, a two

pole auxiliary switch, a ten pole auxiliary switch,

an operation counter, a control panel, an air com

pressor with storage tank, necessary heaters thermo

statically controlled, control equipment, and an all

steel weatherproof, outdoor housing which com

pletely encloses all of the above equipment.

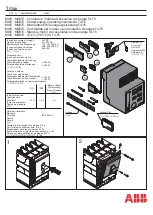

Figs. 1 and 2 show the mechanism in the closed

and latched position with the names of the various

parts. Referring to these figures, the breaker operat

ing rod is connected to the mechanism operating

lever, which is in turn connected to the piston which

operates in the cylinder of the compressed air

mechanism. The main lever is connected through a

link to the mechanism frame. This link allows

enough lateral motion for the piston and vertical pull

rod to keep their alignment throughout the opening

and closing stroke of the mechanism. The trip end

of the operating lever is held closed by a double

latch arrangement.

Caution:

The mechanism is not trip free

from the hand closing device.

Caution should

therefore be taken to make sure that the mechanism

control circuit and breaker disconnecting switches

are open when the mechanism is being operated by

hand, and also that the air supply to the mechanism

is shut off.

The mechanism and its associated equipment is

substantially constructed, and all vital parts such

as pins, pistons, valves, etc., are made of corrosion

resisting materials to insure satisfactory performance

over a long period of time. A 350-watt space heater

which is continuously energized reduces the con

densation of moisture in the housing. Two other

350-watt heaters operated by thermostatic control to

cut in at low temperatures are strategically located

to reduce the danger of moisture freezing around

the valves of the mechanism and compressor. The

compressor should not be started in freezing weather

without first making sure that the heaters have been

on long enough to thaw out valves, etc.-otherwise

the compressor may develop dangerously high

cylinder pressures. The compressor may be dis-

connected by opening the AB breaker in the motor

circuit, leaving the heaters energized.

The closing equipment consists of an air com

pressor with a storage tank and automatic control.

A pneumatic governor is set to maintain the pressure

in the storage tank at a certain value; the com

pressor motor is started when the pressure falls

approximately 15 lbs below this value. The normal

pressure may be set anywhere between 150 lbs

and 200 lbs, depending on the particular breaker

the mechanism is to be used with. Large breakers

will, of course, require higher pressure to close,

while it is desirable to limit the pressure to a lower

value on smaller breakers in order to prevent

undue slamming.

Compressor.

The air compressor is equipped

with a single phase, 60-cycle, 115/230 volt a-c

motor. The motor will be connected for 230 volts

when shipped in order to prevent damage to the

motor from over-voltage unless 115 volt connection

is specified. The air system will be suitable for at

least five operations without recharging. The

system will recharge from atmospheric pressure in

one hour or less. The pressure will build back to

normal after the motor has been started by the

pneumatic governor (15 lbs below normal) in

approximately 5 minutes. The storage tank fulfills all

requirements of State Inspection Codes and is

supplied with suitable accessories. All equipment is

manufactured under the ASME requirements and

receives underwriter inspection before shipment.

Safety Devices.

If anything should go wrong

with the compressor or air equipment so that normal

pressure is not maintained, a low pressure alarm and

cutout switch are provided for indication and pro

tection. The low pressure cutout switch is set to open

the closing control circuit before the pressure drops

too low to close the breaker satisfactorily. The low

pressure alarm switch is set 5 to 10 lbs above this

to close the circuit to the station alarm. A safety

valve is supplied on the storage tank which will pop

off at approximately 15% above the normal operat

ing pressure. This prevents the pressure from build

ing up to a dangerous level if the pneumatic

governor fails to cut off the compressor motor. The

settings of all pressure switches and safety valves

are made at the factory and should not be changed,

except to re-adjust if necessary to settings given on

nameplate mounted on inside of housing door.

3

www

. ElectricalPartManuals

. com