Lit. No. 94430/94431, Rev. 09

21

October 1, 2018

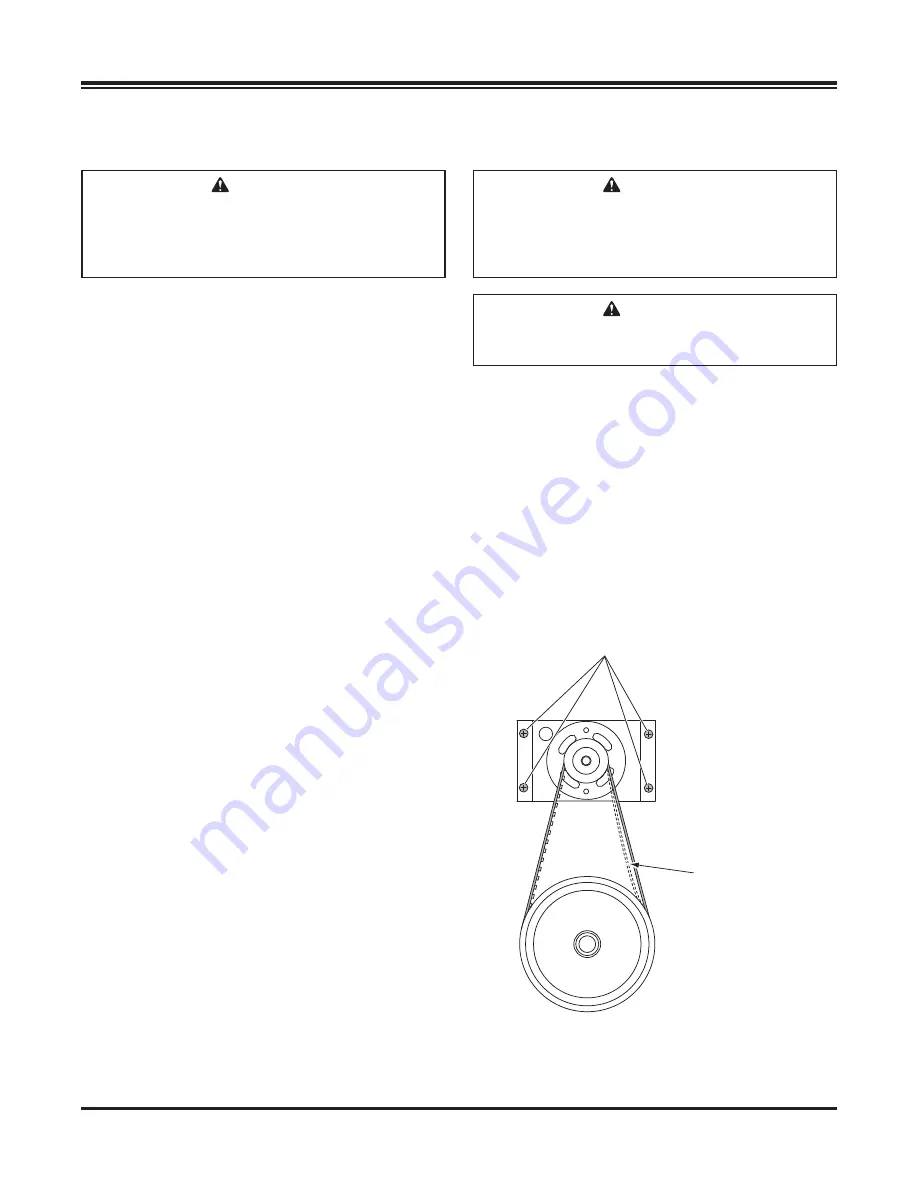

DRIVE BELT REPLACEMENT

1. Disconnect the electrical plug between the spreader

and truck. Remove the motor cap assembly.

2. Loosen the four Phillips head screws that fasten

the motor mount to the drive support.

3. Slide the motor toward the drive shaft.

4. Remove the belt and replace with a new one.

5. Slide the motor mount away from the drive shaft

until the proper tension of the drive belt is achieved.

After tightening the belt should easily de

fl

ect 3/8".

6. Tighten the four Phillips head screws and replace

the motor cap.

CAUTION

Overtightening the belt may result in damage

to the motor or bearings.

Phillips Head Screws

Belt deflects

approx. 3/8"

MAINTENANCE

POSTSEASON MAINTENANCE

Before storing the unit for the off-season, taking a few

minutes to do the following will extend the service life

of your spreader:

1. Thoroughly clean the unit inside and out.

2. Apply dielectric grease to all electrical connections

to prevent corrosion.

3. Grease the drive shaft bearings.

4. Oil or paint all bare metal surfaces.

5. Place the lid on the hopper body of the unit and

secure the latch.

6. Store the unit in an upright position; stabilize it

with supports if necessary. If the unit is stored

outdoors, cover the unit and place it on blocks to

avoid ground moisture.

CAUTION

Disconnect electric power at spreader

electrical wiring harness connection and tag

out if required before servicing or performing

maintenance.

CAUTION

Disconnect electric power at spreader

electrical wiring harness connection and tag

out if required before servicing or performing

maintenance.