To manage recipe click on:

Create a New recipe:

create a recipe file with the standard

default settings

Open existing recipe:

open an existing recipe file

Upload from unit:

create a new recipe with the value

uploaded from a connected power controller

Close:

close the current recipe

Save:

save the recipe in a file

Save as:

save a copy of the recipe in a file

Download to unit:

send the current recipe parameters in the connected power

controller

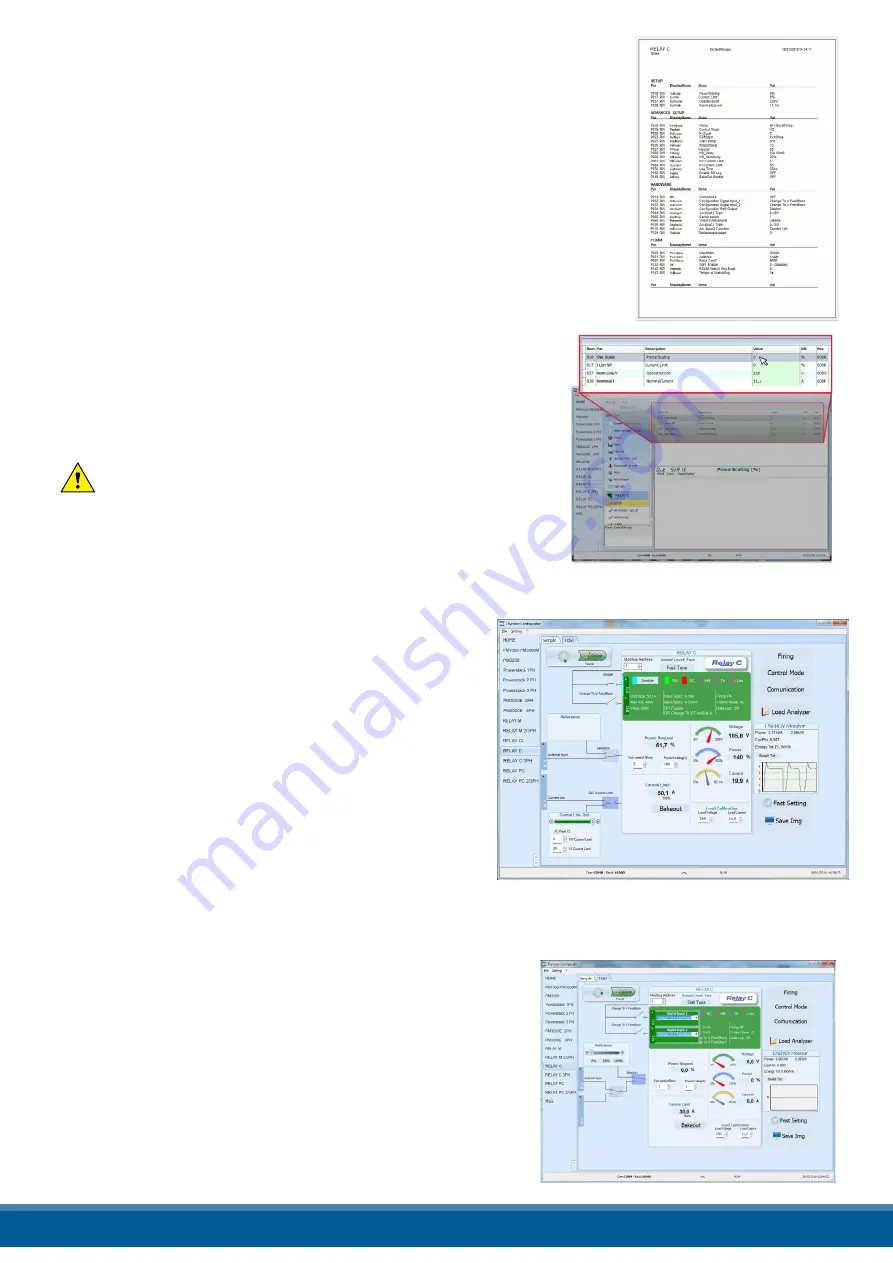

Print: print the recipe (see sample at right)

Print report:

print the recipe (see sample at right)

To edit the actual recipe values click a parameter menu name:

SETUP

ADVANCED SETUP

HARDWARE

COMMUNICATIONS

And after click on the value and modify it.

NOTE!

Changes to the values here affect the open recipe only.

To apply these changes to the power controller settings,

download them to the power controller using the

Download to unit option.

13.6.3 Test Section

This section is used to monitor and adjust the operation

of the power controller in real time using RS485 or USB

communication port.

After select the model, is possible access to this section

clicking the “TEST” tab below the main menu

Operating on TEST Section:

Online button:

is the button to start or stop communication

updates with the power controller

After communication start a green communication

status indicator sweeps clockwise when the software

is communicating right with a power controller, is the

connection link is broken the color will become red

Address:

value used to set the power controller address

Access Level:

click the value to log in or out. Default Password address is “1111”.

To configure and monitor the digital inputs:

Digital input states and functions:

show whether each input detects an open or closed circuit and

the function the input performs

Digital Input States and Function Selectors:

set the function for each digital input. Click DI1 or DI2 to expand

the options.

www.west-cs.co.uk

44