8

EN

2.2 Securing the Danger Zone

The danger zone must be secured by means of the light barriers alone, or by means of the light barriers in

combination with additional mechanical safety devices. Reaching around, over and/or under the safety field must

be prevented in any case. It must be impossible to approach the point of danger without passing through the light

barriers. The safety field is located between the beam emission of the sender and the beam entry at the receiver. The

beam diameter is smaller than 30 mm.

The Light Barriers are only allowed to be used to secure access according to EN ISO 13855. The use for

finger and hand protection is not allowed.

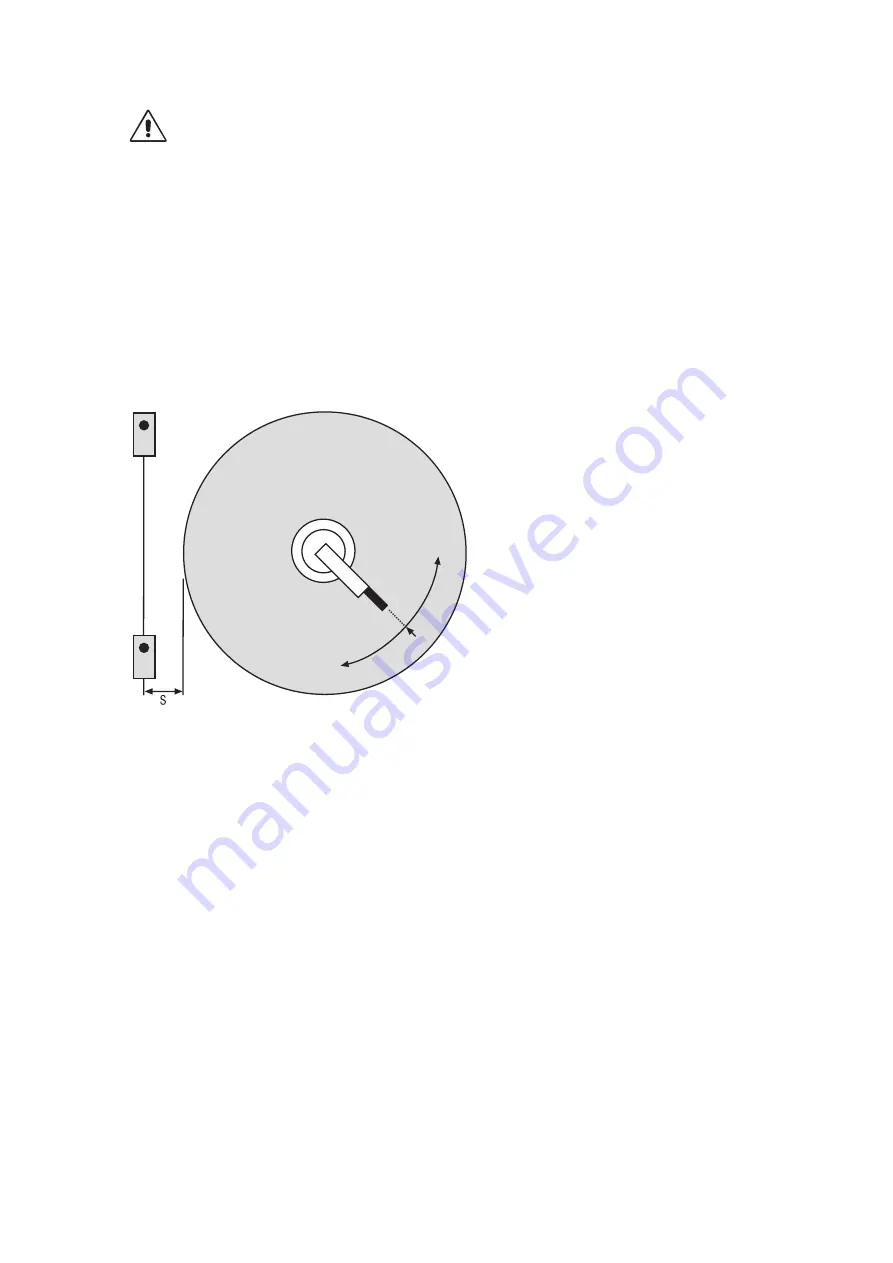

2.3 Safety Clearance per EN ISO 13855

Safety clearance S is calculated with the following formula in accordance with EN ISO 13855: S = K × T +C

A gripping speed of 1,6 meters per second is assumed.

Example:

Danger Zone

Standstill

Standstill

Stop Signal

S = Minimum safety clearance in mm, measured from the danger zone to the point of detection, to the line of

detection or to the safety field.

K = Approach speed constant in mm per sec. = 1600 mm per sec.

T = Total response time (t1 + t2) in seconds

t1 = Response time of the Individual Light Barrier Control Unit in seconds

t2 = Machine or process over-travel time in seconds

C = Additional clearance in mm (margin), which is based upon penetration into the danger zone before the safety

device is triggered

Obstruction of the safety field during hazardous motion results in immediate shutdown. The distance between

the safety field and the point of danger must be large enough to assure that the point of danger cannot be

reached until hazardous motion has come to a standstill. This safety clearance depends upon total over-travel time,

as well as the person’s maximum gripping or walking speed.

Total over-travel time is the sum of maximum response time of the ESPE and maximum over-travel time of the

hazardous motion. Machine over-travel time must be determined by means of repeated measurement prior to

initial start-up, and each time the machine is retooled or set up.

In order to secure the danger zones, the safety heights set forth in EN ISO 13855 are determined by means of a risk

analysis in accordance with EN ISO 13849-1.