9

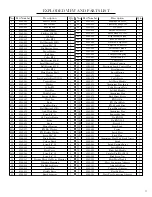

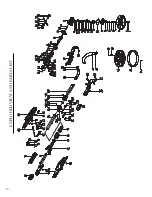

EXPLODED VIEW AND PARTS LIST

No. Part Number

Description

Qty.

1

6369-001

M6X15 Screw

1

2

6369-002

Ø

6 Washer

1

3

6369-003

Sanding Pad

1

4

6369-004

Output Shaft

1

5

6369-005

Flat Key 3X3X10

1

6

6369-006

Oil Seal

1

7

6369-007

Collar

Ø

22

1

8

6369-008

Ball Earing 6900 Rs

1

9

6369-009

Screw M4*12

6

10

6369-010

Big Bearing Cover

1

10A

6369-011

Paper Washer

1

11

6369-012

End Gear

1

12

6369-013

Collar

Ø

10

1

13

6369-014

Ball Bearing 606 Z

2

15

6369-015

Small Bearing Cover

1

16

6369-016

Ball Bearing 699 Z

1

16A

6369-017

Collar

Ø

22

1

17

6369-018

Main Driving Shaft

1

17A

6369-019

Washer

1

18

6369-020

Semi-Circular Key 3X3X10

1

19

6369-021

Tapered Gear

1

19A

6369-022

Washer

1

20

6369-023

Collar

Ø

9

1

21

6369-024

Gear Box

1

22

6369-025

Middle Cover

1

22A

6369-026

Spring Of Rotor

1

22B

6369-027

Wool Cap

1

23

6369-028

Rotor

1

23A

6369-029

Anti-Dust Ring

1

24

6369-030

Ball Bearing 607 Rs

1

25

6369-031

Anti-Wind Ring

1

26

6369-032

Screw St4*55

2

26A

6369-033

4.2 Circular Button

1

27

6369-034

Stator

1

27A

6369-035

Sleeve

1

28

6369-036

Motor Housing

1

28A

6369-037

Ø

4 Flat Washer

4

28B

6369-038

Ø

4 Flexible Washer

4

29

6369-039

Screw M4*20

4

30

6369-040

Brush Holder

2

31

6369-041

Carbon Brush

2

32

6369-042

Screw St3*10

4

33

6369-043

Coil Spring

2

34

6369-044

Back Cover

1

34A

6369-045

Screw St4*12

2

35

6369-046

Screw St4*14

42

36

6369-047

Pressing Block On Motor Housing

1

37

6369-048

Vibration Damping

2

38

6369-049

Big Rubber Sleeve

2

39

6369-050

Screw Pin

2

40

6369-051

Flexible Sleeve

1

41

6369-052

Brush Segment

1

No. Part Number

Description

Qty.

42

6369-053

Sanding Pad Cover

1

48

6369-054

Tightening Ring 25-38

1

49

6369-055

350 Hose

1

50

6369-056

Small Cable Sleeve

1

51

6369-057

Small Rubber Cover

2

52

6369-058

Right Handle Stand

1

53

6369-059

Ø

28 Connector

2

54

6369-060

Plastic Soft PipeØ28

1

55

6369-061

Ellipticle Connector

1

57

6369-062

Left Handle Stand

1

58

6369-063

Washer

Ø

4

4

59

6369-064

Compressed Spring

4

60

6369-065

Electric Sensor

2

61

6369-066

Cable Plate

2

62

6369-067

Electric Capacity

1

63

6369-068

Electronic Speed Control Plate

1

64

6369-069

Potentiometer

1

65

6369-070

Speed Button

1

67

6369-071

Cable

1

68

6369-072

Cable Sleeve

1

69

6369-073

Left Main Handle

1

70

6369-074

Aluminium Pipe Insert

1

71

6369-075

Cable Pressing Plate

1

72

6369-076

Left Sub-Handle

1

73

6369-077

Aluminium Pipe

1

73A

6369-078

Back Hinge Sleeve

1

73B

6369-079

Ø

5X45Pin

1

73C

6369-080

Ø

5 Clinch Bolt

2

73D

6369-081

Ø

1.2 Sealed Ring

1

73E

6369-082

Front Hinge Sleeve

1

73F

6369-083

Aluminium Pipe

1

73M

6369-084

Supporting Arm

2

73P

6369-085

Pin

Ø

5X30

1

73Q

6369-086

Pin

Ø

5X16.8

1

73H

6369-087

Sleeve 2#

1

73I

6369-088

Front Latch

1

73J

6369-089

Spring

1

73K

6369-090

Latch Pivot

1

73L

6369-091

Fixed Plate

1

74

6369-092

Aluminium Pipe With Single Access

1

75

6369-093

Switch

1

76

6369-094

Switch Pushing Lever

1

77

6369-095

Switch Button

1

78

6369-096

Right Sub-Handle

1

79

6369-097

Circular Pin

Φ

1.5X11.8

1

80

6369-098

Back Screw Nut

2

81

6369-099

Right Main Handle

1

82

6369-100

Hose Connection Adapter

1

83

6369-101

Adjustable Ring

1

84

6369-102

Connection Adapter

1

/

6369-103

Flexible Hose

1

/

6369-104

Dust Port Connection Adapter

1

Summary of Contents for 6369

Page 10: ...10 EXPLODED VIEW AND PARTS LIST...

Page 12: ...Thanks for remembering...