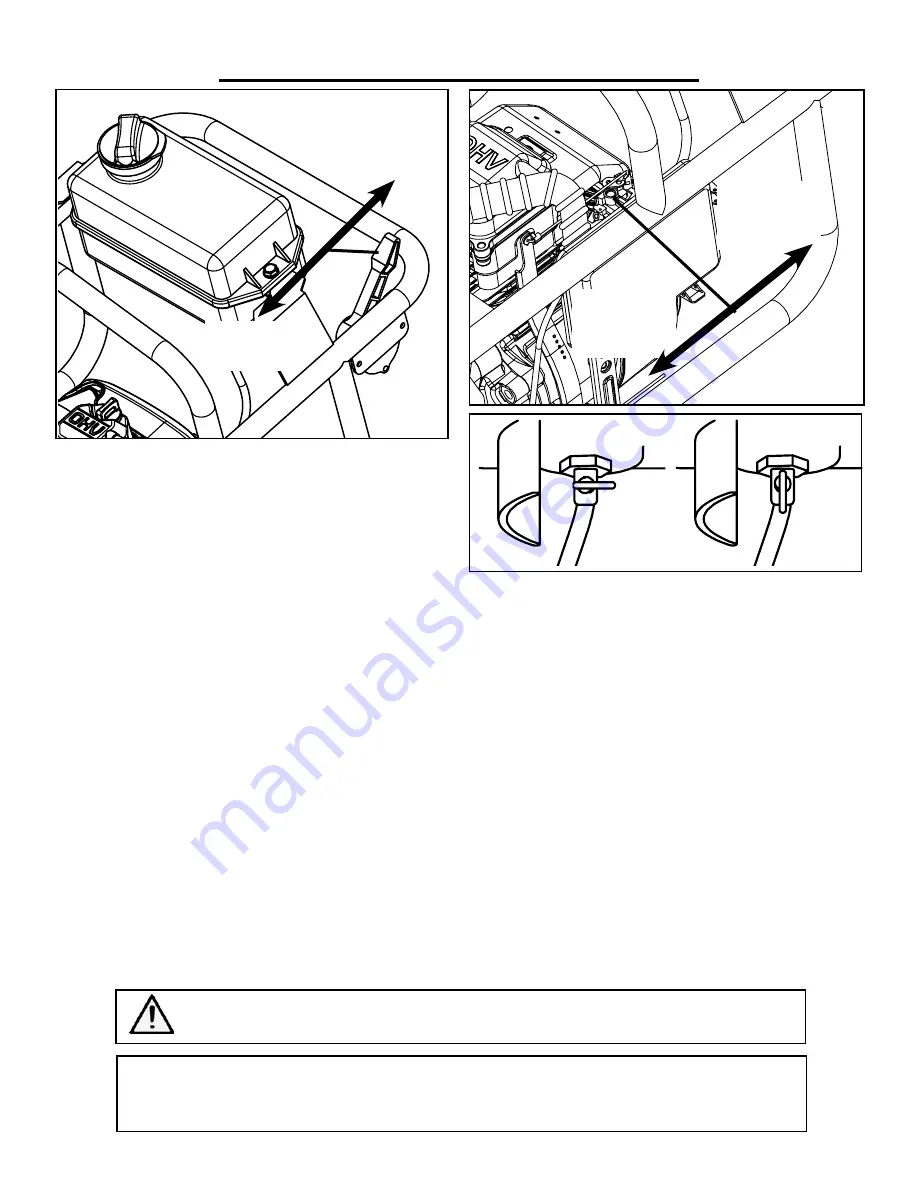

Closed/Start

(away from

recoil starter)

Open/Run

(towards

recoil starter)

Choke - Fig. 5

low the engine to run for 3 to 5 minutes to properly warm everything up.

2. To begin tamping, quickly move the throttle from the lowest position to its MAX THROTTLE position (Fig. 4).

DO NOT move the throttle slowly, as doing so may cause damage to the clutch or spring.

CAUTION: Make sure that the throttle lever is moved to the MAX THROTTLE position upon startup. Otherwise

you run the risk of damaging the tamping rammer.

3. Once the tamping action has commenced, adjust the jumping motion to best suit the conditions of the soil by

lightly adjusting the throttle lever. Increasing the engine speed does not increase compaction force. In fact, unneces-

sarily high operating speeds will cause the subsequent impaction force to decrease.

NOTE: Keep in mind that in cold weather (below 40°F), the oil may become viscous, resulting in irregular move-

ments of the rammer. It is recommended to perform a warm-up run while moving the throttle lever repeatedly

between MAX and MIN positions before attempting to use the rammer.

4. The tamping rammer has been designed to advance forward during its tamping operations. To advance at a

quicker speed, push down slightly on the handle so that the flat surface of the foot at the rear-end of the machine

contacts the ground.

Max Throttle

(high speed)

Min. Throttle

(low speed)

11

OPERATION

CAUTION

: Allowing gasoline to sit in the fuel tank for long periods of time can make it dif-

ficult to start the tamping rammer in the future. Never store the rammer for extended periods

of time with fuel in the fuel tank. Refer to Storage Section.

WARNING

: Allow the unit to cool for several minutes before touching areas that

become hot during use.

Fig. 4

Open

Closed

Fig. 6

STARTING THE TAMPING RAMMER

NOTE: For operation, the user should stand on the side

of the rammer with the gas tank.

1. Once you have started the engine (as in the choke is

open and the engine is running on its lowest speed), al-