17

16

CAUTION! Saw blades are sharp. Always wear

ANSI Z87.1-approved eye protection, as well as

protective gloves, while handling saw blades.

CAUTION! Always be sure that the band saw

is turned OFF and unplugged before making any

adjustments.

OPERATION

Fig. 22

GENERAL CUTTING GUIDELINES

1. Make a test cut on scrap wood to test the settings and

get the hang of operating the band saw.

2. Make all adjustments with the band saw turned OFF

and unplugged.

3. Make sure the upper guard is close to the upper face

of your workpiece (see Adjusting the Upper Blade Guide

on page 14). Always use a push stick when cutting in-

tricate or narrow workpieces. Keep fingers, hands, and

other beloved body parts away from the blade!

4. Do not force the workpiece against the blade. Let the

tool do the work. Light contact gives easier cutting and

prevents excess friction, which will prolong the life of

the blade and prevents workpiece burning.

5. Always use dust collection. A dust port is located on

the back of the saw, next to the motor (p. 10 - O). Use a

hose clamp (if necessary) to secure the adapter or dust

hose to the dust port.

6. The band saw is most suitable for straight-line cut-

ting (cross-cutting, ripping, miter cutting, beveling,

compound cutting, and resawing). While it can certainly

cut curves, it is not a scroll saw, and cannot perform the

same kinds of cuts. Do not cut sharp corners; instead,

saw around corners.

CUTTING CURVES

When cutting curves, carefully turn the workpiece so

that the blade follows the cut line without twisting. If the

curve is so sharp that you repeatedly back up and cut

new kerf, use a narrower blade, or a blade with more set

(that is, the teeth are further apart). When a blade has

more set, the workpiece turns more easily, but you will

get a rougher cut.

When changing a cut, do not withdraw the workpiece

from the blade – the workpiece may drag the blade off

the wheels. Instead, turn the workpiece and cut out

through the scrap section of the workpiece. When cut-

ting long curves, make relief cuts as you go along.

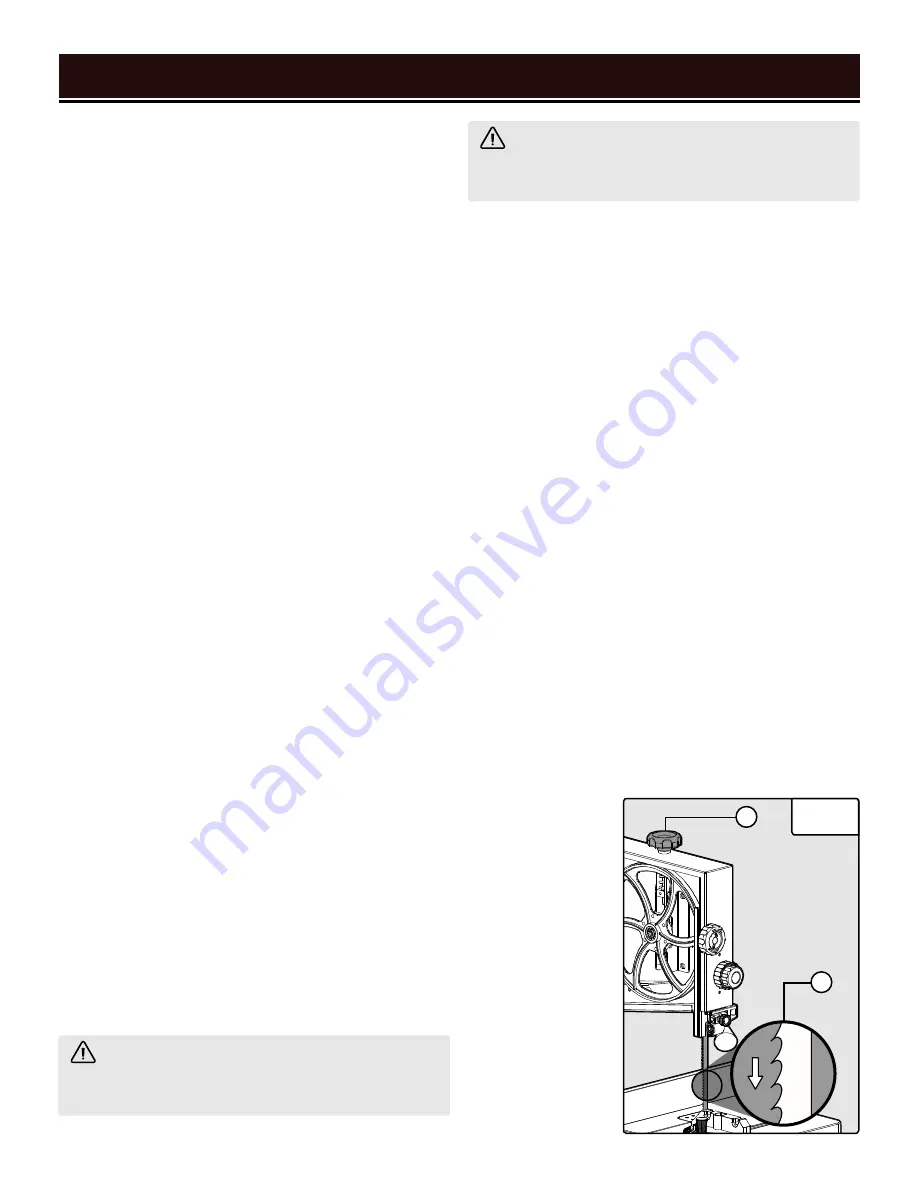

CHANGING BLADES (FIG. 22)

1. Double-check that the band saw is turned OFF and

disconnected from the power source. Open the upper

and lower doors.

2. Loosen the four guide rail lock knobs (you do not

have to completely remove the knobs), and slide the

guide rail off.

3. Turn the blade tension knob (A) to relieve tension on

the blade.

4. Remove the blade from the wheels and from between

the upper and lower bearing guides. Guide it through

the table slot. Store the blade in a safe place.

5. Guide the new blade through the table slot, spine

first. The blade teeth should be facing you, pointing

down towards the table (B).

6. Place the blade on the upper and lower wheels, and

between the bearing guides.

7. Tension the blade (see Adjusting the Blade Tension

on page 14).

8. Adjust the blade tracking (see Adjusting the Blade

Tracking on page 13).

9. Adjust the upper

and lower bearing

guides (see on

page 14 - 15).

10. Replace the

guide rail. Tighten

the lock knobs.

11. Make a test cut

on a scrap piece

of wood before

resuming cutting.

B

A