15

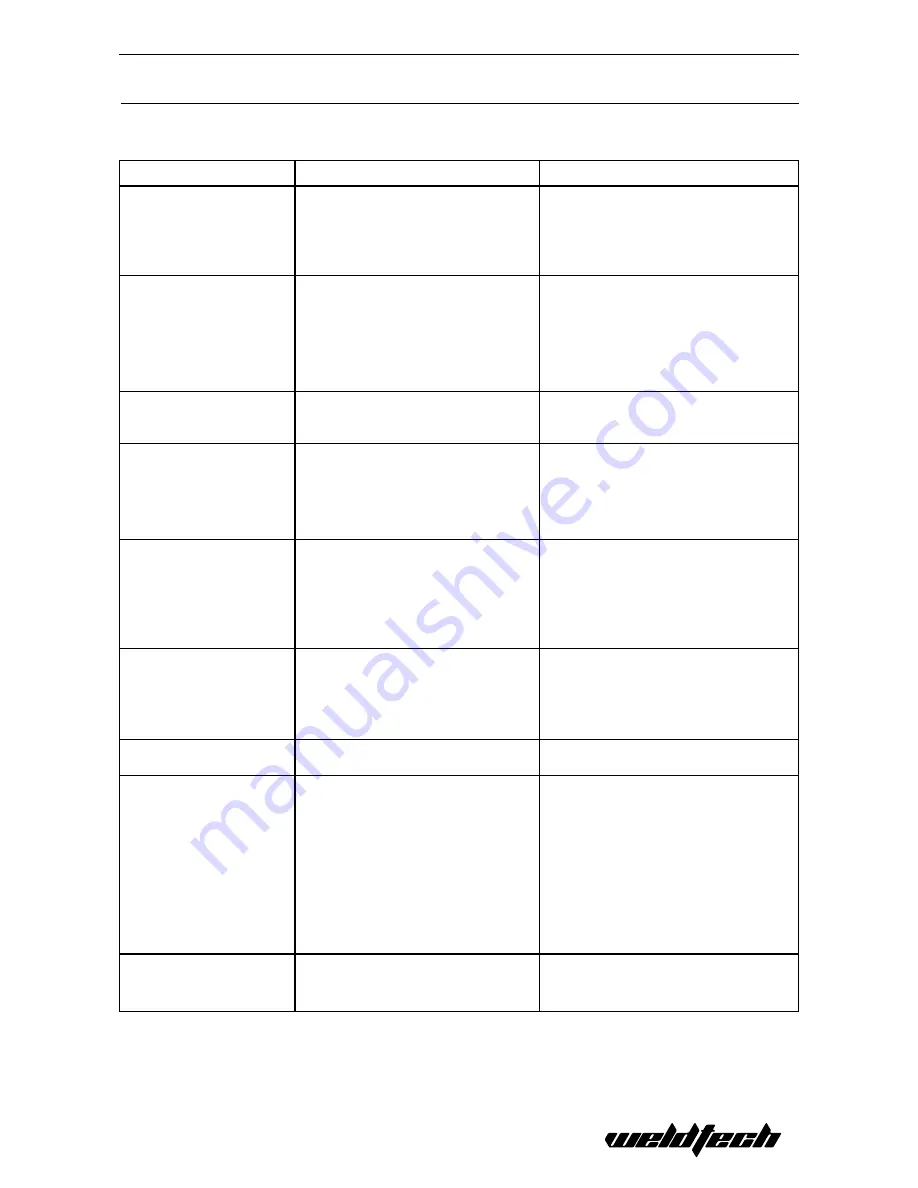

Troubleshooting

• Extension cord being used is not heavy

duty

PROBLEM

CAUSE

SOLUTION

Torch will not come on

• Power switch OFF

• Air supply is not of sufficient volume or

pressure

• Work piece ground clamp not attached.

• Turn power switch to the ON position

• Check air supply (60–80 PSI, 3.5cfm required)

• Attach to work piece or to steel table with

work piece securely clamped to table

Sparks are shooting upward

instead of down through the

material.

• Plasma torch is not piercing the material

• Torch may be too far away from the

workpiece

• Material may not be earthed properly

• Travel speed too fast

• Increase current

• Decrease the distance of your torch to the

workpiece

• Check connections for proper earth

• Reduce speed

Beginning of cut not

completely pierced

• Possible earth connection problem

• Check all connections

Dross build-up on parts of

cuts

• Tool/material building up heat

• Cutting speed too slow or current too

high

• Worn torch parts

• Allow material to cool then continue cut.

• Increase speed and/or reduce current until

dross is reduced to minimum

• Inspect and repair or replace worn parts

Arc stops while cutting

• Cutting speed too slow

• Torch is too high, away from material

• Worn torch parts

• Workpiece earth cable disconnected

• Increase speed until problem solved

• Lower torch to recommended height

• Inspect and repair or replace worn parts

• Connect workpiece earth clamp to work

piece or steel table.

Insufficient penetration

• Cutting speed too fast

• Torch tilted too much

• Metal too thick for plasma capacity

• Worn torch parts

• Slow down travel speed

• Adjust tilt

• Several passes may be necessary

• Inspect and repair or replace worn parts

Arc sputters/flares

• Water in the air supply

• Install air drier or additional filtration

Consumables wear quickly

• Exceeding unit capability

• Excessive ARC starting HF use

• Improperly assembled torch

• Inadequate air supply, pressure too low

• Faulty air compressor

• Material too thick, increase angle to

prevent blow back into torch tip

• Do not operate HF ARC starting for more

than 3 seconds - you can also start with

torch in contact with metal or within 1/16”

of metal

• See section ‘Replacing Consumables’

• Check air filters, increase air pressure

• Check air compressor operation and make

sure input air pressure is at least 100 PSI

Circuit breaker/fuse trips

while operating

• Use a heavy duty extension cord (2.5mm

diameter)

If you have any problems in setting up or operating the machine,

please first re-consult this manual.

Summary of Contents for SC40C

Page 1: ...OPERATING INSTRUCTIONS SC40C 40A INVERTER PLASMA CUTTER www weldtech net nz ...

Page 16: ...16 ...

Page 18: ...18 ...

Page 19: ...19 ...