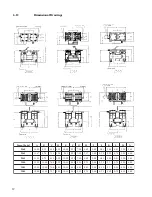

7.20

Vacuum System for Vacuum Chamber,

Glove Box, Annular Space & Transfer Line

2561B-50

2561C-50

2561C-56

2581B-50

2581C-50

2581C-56

7.21

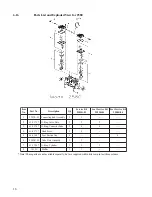

System Components

* used on 2561B & 2581B

** used on 2561C & 2581C

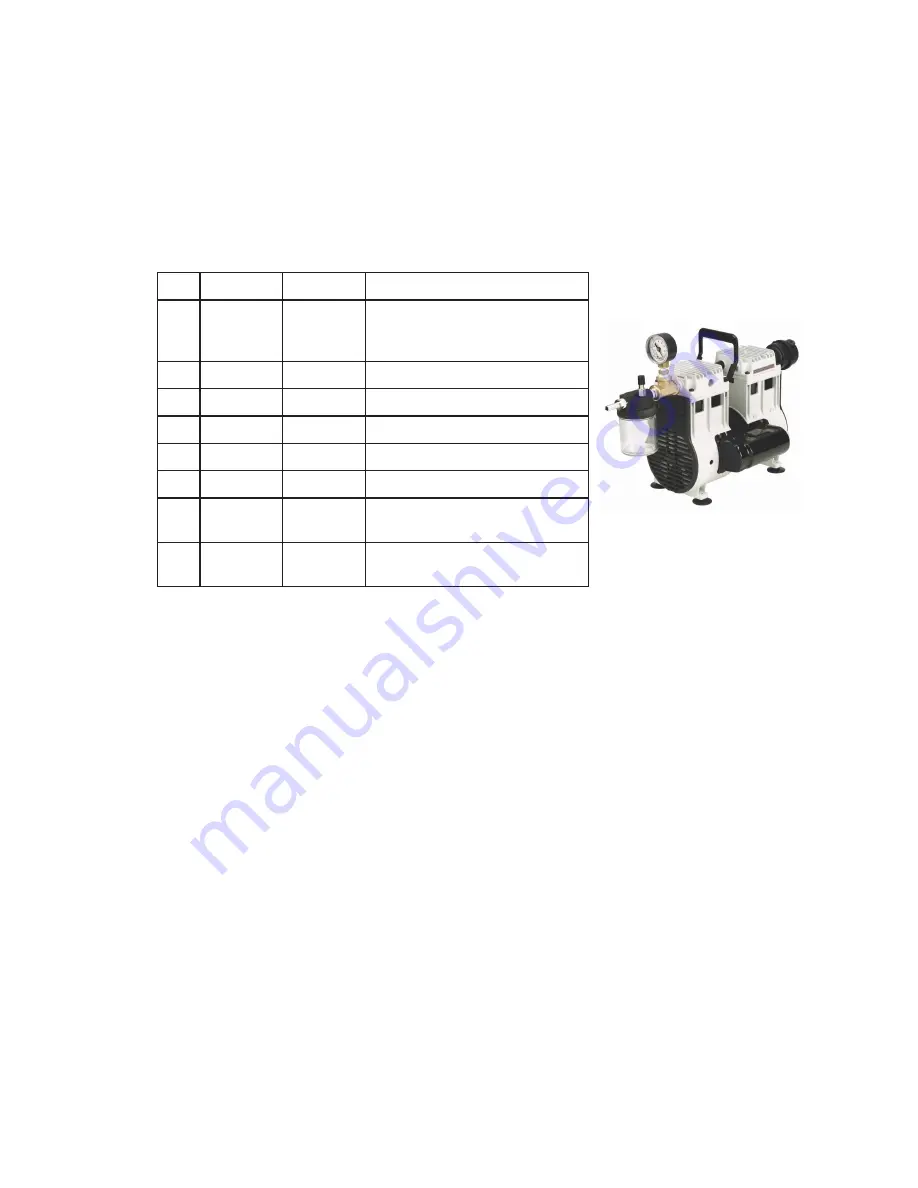

7.22

System Operation

Welch’s new portable oil-free general utility roughing pumps provide continuous, reliable vacuum that your

vacuum chamber, glove box, annular space and transfer line applications require. The pumping mechanism

is an economical twin head oil-free Wob-L® known for reliability and durability. These rugged pumps

handle 20,000 plus roughing cycles – from atmospheric to 5 Torr – before needing seal maintenance.

The pumps come completely equipped and ready to use. An inlet trap to help prevent ingestion of fluids into the

pump, a dial gauge for continuous vacuum level monitoring, and a vacuum regulator to adjust vacuum levels.

Just plug it in and you’ re up and running.

Choose Model 2581B-50 for evacuating vacuum ovens, annular spaces, transfer lines and purging a glove box

up to 30 cubic feet. For Vacuum Ovens, Model 2561B-50 is suited for 1.5 cubic foot ovens or smaller and Model

2581B-50 can be used for up to 3.5 cubic feet.

The pumping speed of the 2561 and 2581 at rough vacuum levels is equal to oil-seal rotary vane pumps of similar

size. This makes the 2561 and 2581 an economical, oil-free solution for replacing oil-seal rotary vane pumps.

These pumps are therefore highly recommended for standard duty laboratory applications, general vacuum work

and where quick roughing of a chamber is needed.

The 2581 and 2561 pump Models are for use in standard duty applications. This means that they are not recom-

mended for pumping acidic, basics or organic vapors or gasses. If you are looking for a pump to handles these

types of conditions, contact a Welch representative and they will be able to assist you in selecting the correct

pump for your application.

.

y

t

Q

1

6

5

2

1

8

5

2

n

o

i

t

p

i

r

c

s

e

D

1

1

r

o

1

r

o

4

2

-

B

1

6

5

2

4

2

-

C

1

6

5

2

5

2

-

C

1

6

5

2

4

2

-

B

1

8

5

2

4

2

-

C

1

8

5

2

5

2

-

C

1

8

5

2

h

P

1

,

z

H

0

6

,

V

5

1

1

,

p

m

u

P

h

P

1

,

z

H

0

6

/

0

5

,

V

0

3

2

,

p

m

u

P

h

P

1

,

z

H

0

6

/

0

5

,

V

0

0

1

,

p

m

u

P

1

6

7

5

3

-

1

6

6

7

5

3

-

1

6

d

e

n

i

h

c

a

M

,

y

l

b

m

e

s

s

A

r

a

J

1

2

4

1

5

-

1

6

2

4

1

5

-

1

6

e

r

u

t

a

i

n

i

M

e

v

l

a

V

e

l

d

e

e

N

1

8

4

1

5

-

1

6

8

4

1

5

-

1

6

k

c

a

l

B

d

e

t

u

l

F

,

b

o

n

K

t

n

e

m

u

r

t

s

n

I

1

4

5

3

0

-

2

6

4

5

3

0

-

2

6

T

P

N

"

8

/

3

,

b

r

a

B

e

s

o

H

1

6

3

1

0

-

6

6

6

3

1

0

-

6

6

r

a

n

y

K

t

h

g

i

a

r

t

S

e

l

a

M

b

r

a

B

1

6

6

0

1

-

2

6

2

7

3

0

-

2

6

6

6

0

1

-

2

6

"

1

x

"

8

/

3

e

l

p

p

i

N

"

4

/

1

x

"

8

/

3

g

n

i

c

u

d

e

R

x

e

H

e

l

p

p

i

N

1

1

r

o

*

4

9

4

3

-

1

6

*

*

5

9

2

1

-

1

7

*

4

9

4

3

-

1

6

*

*

5

9

2

1

-

1

7

g

H

n

i

/

a

P

k

,

e

g

u

a

G

m

u

u

c

a

V

g

H

n

i

/

g

H

m

c

,

e

g

u

a

G

m

u

u

c

a

V

20

Summary of Contents for 2560

Page 11: ...6 11 Pumping Speed Curves 11 ...

Page 21: ...21 ...