20

Part Number: 9294045 07/19

Maintenence Section3

20 - Ordinary Maintenance

20.1 Operations by the user that do not require the

assistance of a qualified technician

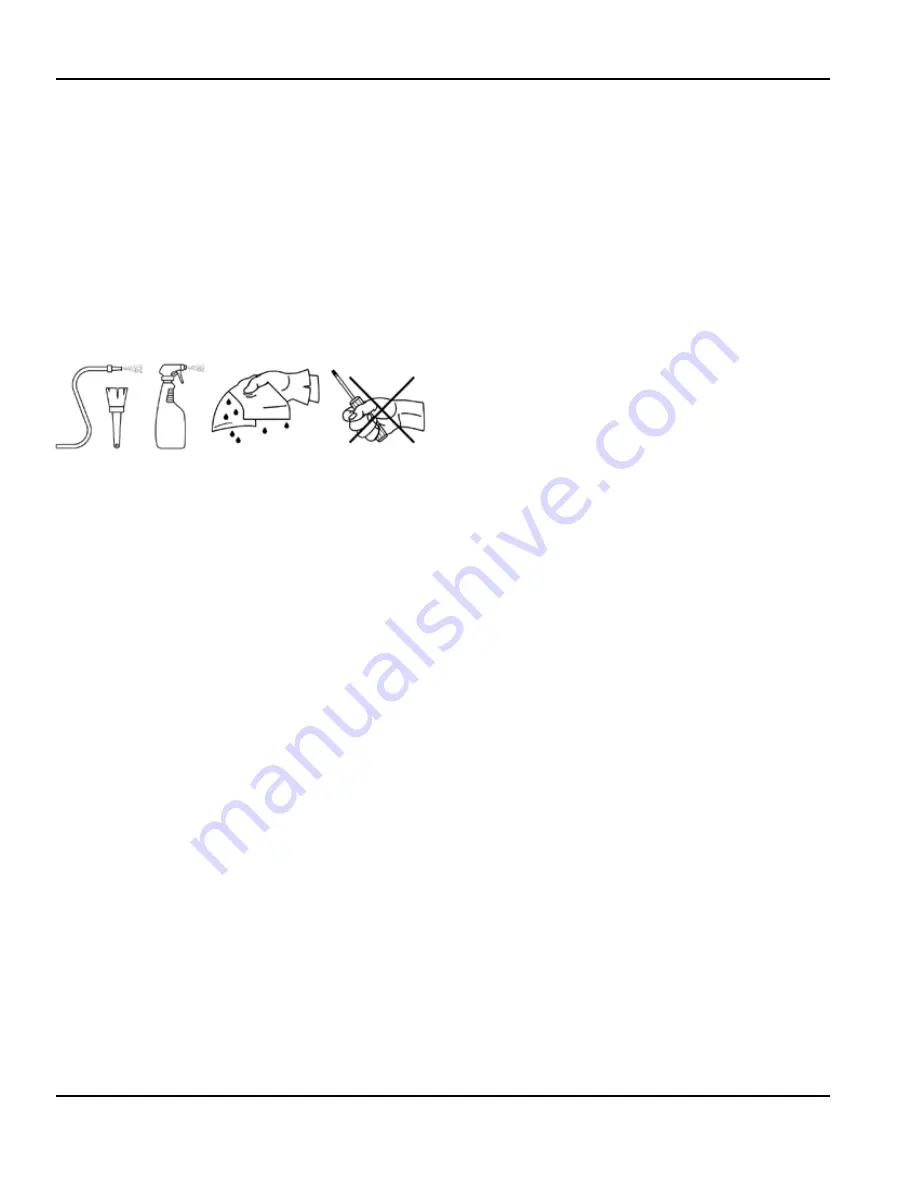

20.1.1 - Cell cleaning

In order to ensure hygiene and protection of the quality

of the food being processed, interal cleaning of the cell

must be performed frequently, depending on the type of

food stored.

Suggested frequency: weekly cleaning.

- The shape of the cell and of the internal components

allow its cleaning using a cloth or sponge.

- Clean with water and non-abrasive neutral detergents.

Rinsing is possible with a cloth or sponge soaked in water

or with a moderate water jet (not exceeding the system

pressure). Do not scrape the surfaces with sharp or

abrasive items.

20.1.2 - Outer casing cleaning

For cleaning of the casing simply use a cloth dampened

with a chlorine-free product, suitable for stainless steel.

20.1.3 - Defrost water drainage

The system was designed for automatic and manual

defrosting when needed.

Check for correct water drainage of the evaporator on

the drop tray (if supplied), avoiding the occurrence of

obstructions of the drainage pipe.

,

20.2 - Operations only for authorised installer

Below are listed the routine maintenance operations

that must only be performed by qualified installation

techinicians. The manufacturer declines all liability

for accidents caused by non-compliance with the

requirement.

Below is a list of operations useful to preserve the efficient

operation of the appliance with related recommended

frequencies.

Detailed maintenance operations are described in the

Service Manual kept by installers and qualified technicials.

20.2.1 - Condenser cleaning

(for air cooled models only)

For the correct and efficient operation of the condenser,

the air cooled condenser must be kept clean to allow the

circulation of air.

Recommended frequency: operation to be performed

every 30 days or in any case according to the working

condintions of the appliance (the presence of dust and

flour in the work environment of the appliance significantly

affects dirt accumulation of the condenser thus making it

less efficient).

20.2.2 - Condenser filter cleaning

(for air cooled models only)

Recommended frequency: operation to be performed

every 30 days or in any case according to the working

condintions of the appliance (the presence of dust and

flour in the work environment of the appliance significantly

affects dirt accumulation of the condenser thus making it

less efficient).

20.2.3 - Evaporator cleaning

For the correct and efficient operation of the appliance,

the evaporator battery must be kept clean to allow free

air circulation and especially to remove food residue and

grease the can be a source of bacteria harmful to human

health.

Suggested frequency: operation to be performed every 30

days or depending on the type of food being processed.

20.2.4 - Ozonator maintenance

Dirty and dusty environments reduce efficiency of the

ozonator: for longer lamp life and for greater efficiency,

the bulb of the ozonator should be cleaned periodically. To

ensure maximum fucntionality the bulb must be replaced

every 12 months.

For the correct maintenance and cleaning practices

comply with the instructions in the service manual.

Suggested frequency: clean the lamp of the ozonator at

least every 3 months.

Replacement of the lamp every 12 months (only genuine

spare parts).

21 - TIPS FOR SMOOTH OPERATION

21.1 - Operating instructions

Before operating the machine it is necessary to perform

thorough cleaning inside the cell.

21.2 - Pre-cooling

Before using the machine for the first time or after a period

of disuse. pre-cool the cell by running the machine empty

until it reaches the working temperature set.

To obtain good performance of the machine and to aviod

food alterations, it is advisable to:

• stack the products in order to promote the

Summary of Contents for Delfield CV10E

Page 22: ...22 Part Number 9294045 07 19 Troubleshooting Section 4 T40 BLast Chiller Shock Freezer ...

Page 25: ...Part Number 9294045 07 19 25 Section 4 Troubleshooting T5 T14D Refrigeration System Schematic ...

Page 26: ...26 Part Number 9294045 07 19 Troubleshooting Section 4 T5 T14D Wiring Diagram ...

Page 31: ...Part Number 9294045 07 19 31 Section 4 Troubleshooting Controller Buttons ...

Page 41: ...Part Number 9294045 07 19 41 Section 4 Troubleshooting THIS PAGE INTENTIONALLY LEFT BLANK ...