Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners

14

Part No. 550-141-935/0602

Connect water boiler piping

7

General water piping information:

•

System water supply and return piping should be installed and piping

connections attached to boiler before erecting jacket or installing controls.

•

Do not pipe in through supply and out through return. This creates reverse

water flow through boiler that must not be used.

•

When three-way valves are used for temperature modulation, install slow-

opening (minimum 10-minute) valves and boiler mixing pump to minimize

potential of boiler thermal shock. See W-M Bulletin AE-8402.

Install piping:

Install piping as shown in Figure 12 for single boilers. For multiple boilers, see

Figure 13, page 15.

Improperly piped systems or undersized piping can contribute

to erratic boiler operation and possible boiler or system

damage.

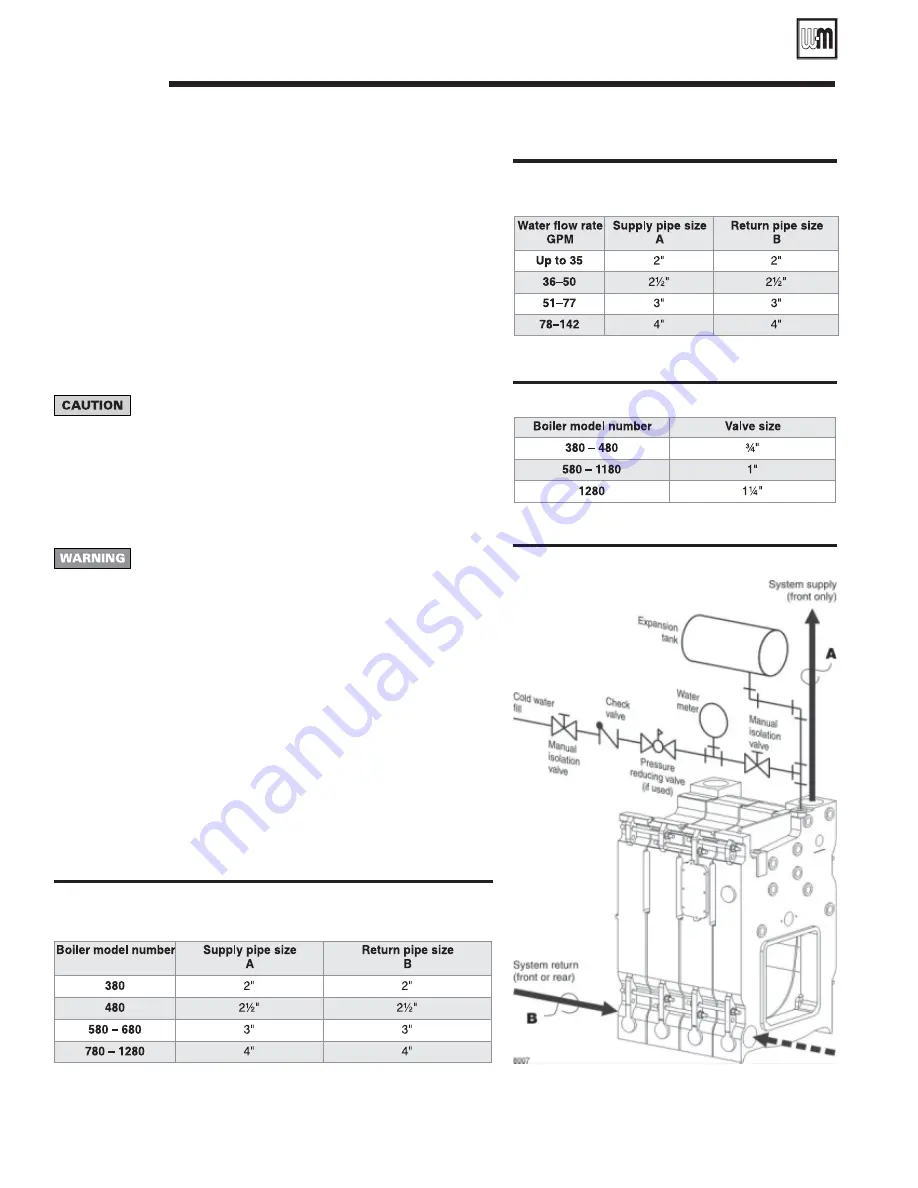

1. Connect supply and return piping:

a. Size according to tables below.

1) For

unknown flow rates

, size piping per Table below, using 20°F.

temperature rise through boiler.

2) For

known flow rates or higher flow rate

through boiler, size

piping per Table below.

Flow at higher rates than shown in Table below for pipe size

can damage boiler, causing substantial property damage.

b. Locate circulator in supply piping.

c. For return piping, use full diameter pipe for 10 times that diameter before

making any reduction. For example, a 4-inch return should not be

reduced any closer to boiler return tapping than 40 inches.

d. Install system blow-off (drain) valve in lowest part of return piping close

to boiler. ASME minimum size requirements are shown in Table 5.

2. Install expansion tank:

a.

Closed type

– connect to 1" tapping “K” (refer to pages 28 and 29).

Use 1” N.P.T. piping. Any horizontal piping must pitch up toward tank

at least 1 inch per each 5 feet of piping.

b.

Diaphragm type

– Refer to tank manufacturer’s literature for location.

Install automatic air vent in “K” tapping.

c. Connect cold water fill to expansion tank piping. See Figure 12, page 14.

Also shown are recommended valves and water meter, when used. Water

meter will detect added make-up water, indicating leaks in system.

Table 7

ASME drain valve size

Table 6

Recommended minimum pipe sizes for

known flow rates.

Table 5

Recommended minimum pipe sizes when flow rate is

not known (see Figure 12)

Figure 12

Water boiler piping, typical