36 l

Installation, operation and maintenance manual – Squirrel cage motor – WGM20 Line 14108242

Drying oil is used to protect the motor shaft against rust

during transportation. In order to ensure the proper

operation of the grounding brush, this oil, as well as any

residue between the shaft and the brush, must be

removed before starting the motor. The brush must be

constantly monitored during operation, and it must be

replaced by another one of the same quality (granulation)

at the end of its useful life.

7.9

ENCODER MAINTENANCE

The correct installation of the encoder (if any) is very

important for its operation. Both disassembly and

assembly must be done by skilled and trained personnel,

according to the procedures contained in the specific

manual of the equipment manufacturer.

If any further explanations are necessary, consult WEG.

7.10

BEARING MAINTENANCE

7.10.1

Bearing data

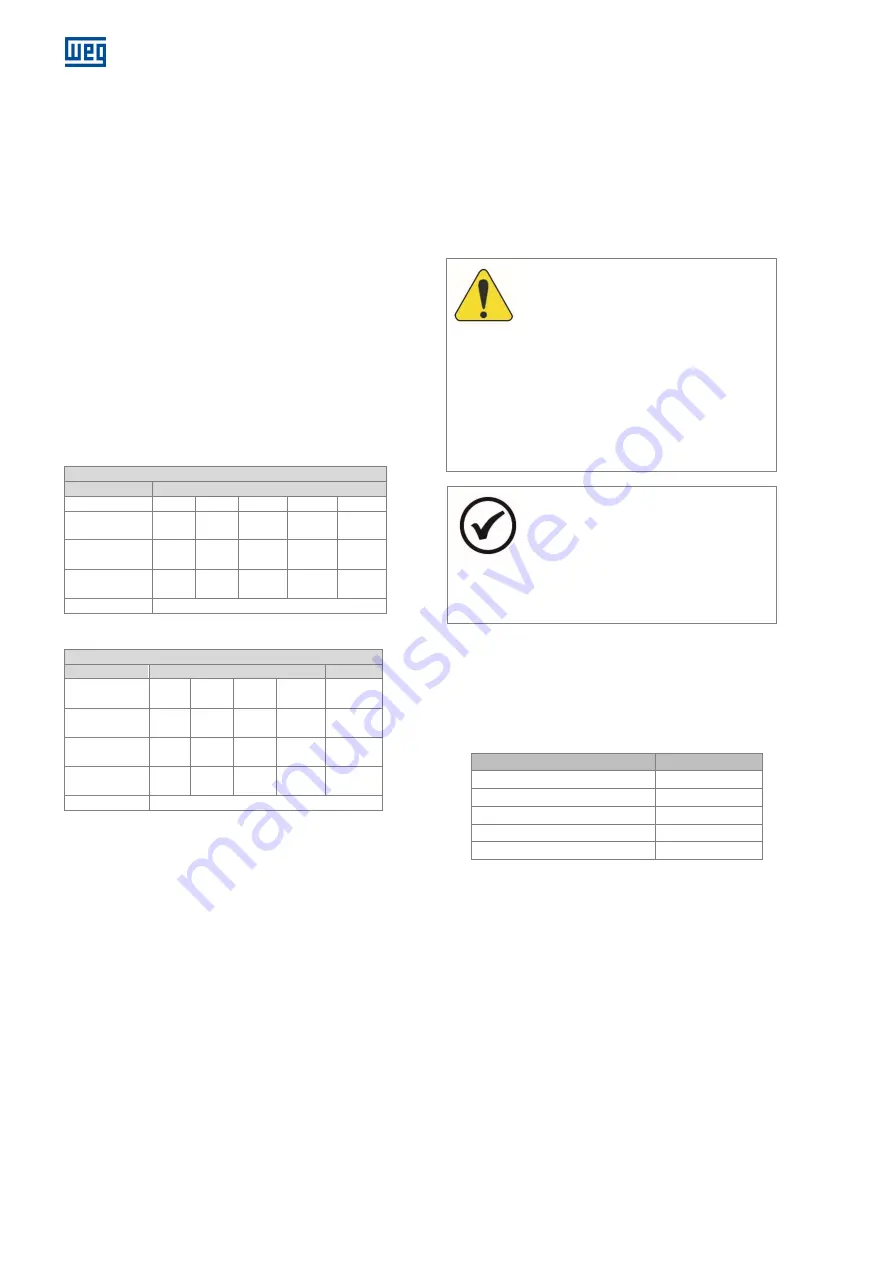

Table 7.1: Bearing data: horizontal motors

Bearing data – Horizontal motors

Front and Rear

Frame

355

400

450

500

560

Rolling

Bearing

6222 6224

6228

6232

6232

Grease

quantity (g)

38

43

52,5

69,6

69,6

Lubrication

interval (h)

4500 4500

4420

3420

3420

Grease

Polirex EM 103

Table 7.2: Bearing data - vertical motors

Bearing data – Vertical motors

Front

Rear

Frame

355

400

450

500

355 to

500

Rolling

Bearing

6222 6224

6226

6232

7222

Grease

quantity (g)

41

43

46

69,6

38

Lubrication

interval (h)

4500 4500

4500

3270

2240

Grease

Polirex EM 103

7.10.2

Instructions for lubrication

The lubrication system was designed in such a way that

during the lubrication of the rolling bearings, all the old

grease is removed from the rolling bearing races and

expelled through a drain which enables the exit of the

grease, but prevents the ingress of dust or other harmful

contaminants.

This drain also prevents damage to the rolling bearings by

excessive lubrication.

It is recommended to make the lubrication with the motor

in operation in order to ensure the renewal of the grease in

the rolling bearing housing.

If that is not possible due to the presence of rotating parts

near the grease nipple (pulleys, etc.) which may put the

operator at risk, follow the procedures below:

With the motor stopped, inject approximately half of the

total intended amount of grease and operate the motor

for approximately one minute at full speed;

Stop the motor and inject the rest of the grease.

ATTENTION

The injection of all the grease with the

motor stopped may lead to the penetration

of part of the lubricant into the motor

through the internal seal of the rolling

bearing cap;

It is important to clean the grease nipples

prior to lubrication in order to prevent

foreign materials from being dragged into

the rolling bearing. For lubrication, use only

manual grease gun.

NOTE

The rolling bearing data, amount and type

of grease, and lubrication intervals are

informed in Table 7.1, Table 7.2 and on a

bearing nameplate fixed to the motor.

Check this information before performing

the lubrication.

The lubrication intervals informed consider the working

temperature of the rolling bearing of 70ºC;

Based on the operating temperature ranges listed in

Table 7.3, apply the following correction factors for the

rolling bearing lubrication intervals:

Table 7.3: Reduction factor for lubrication intervals

Bearing operating temperature Reduction factor

Below 60 ºC

1.59

Between 70 and 80 ºC

0.63

Between 80 and 90 ºC

0.40

Between 90 and 100 ºC

0.25

Between 100 and 110 ºC

0.16

7.10.3

Procedures for bearing lubrication

1.

Clean with a cotton cloth around the hole of the

grease nipple;

2.

With the rotor operating, inject the grease with a

manual grease gun until grease starts coming out from

the drain or until the proper amount of grease,

informed in Table 7.1 and Table 7.2 has been injected.

3.

Keep the motor running long enough so that the

grease excess passes through the drain;

4.

Inspect the bearing temperature to make sure there

was no significant change;