www.weg.net

WEG Molded Case Circuit Breakers - User’s Manual

10

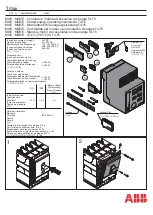

Adjustment

buttons

Figure 8:

trip unit magnetic trip adjustment buttons

3.5. INSPECTION AND FIELD TESTING

UBW250 molded case circuit breakers are designed to provide years of almost

maintenance-free operation.

The following procedure describes how to inspect and test a circuit breaker in

service.

3.6. INSPECTION

Circuit breakers in service should be inspected periodically. The inspection should

include the following checks (4-1 through 4-8):

WARNING

The voltages in energized equipment can cause death or severe personal

injury. Before inspecting the circuit breaker in an electrical system, make

sure there is no voltage present where work is to be performed. Special

attention should be paid to reverse feed applications to ensure no voltage

is present.

CAUTION

Make sure that cleaning agents or solvents used to clean the circuit breaker

are suitable for the job. Some commercial cleaning agents will damage the

nameplates or molded parts.

1. Remove dust, dirt, soot, grease, or moisture from the surface of the circuit

breaker using a lint-free dry cloth, brush, or vacuum cleaner. Do not blow

debris into circuit breaker. If contamination is found, look for the source and

eliminate the problem.

2. Switch circuit breaker to ON and OFF several times to be sure that the

mechanical linkages are free and do not bind. If mechanical linkages are not

free, replace circuit breaker.

3. With the circuit breaker in the ON position, press the PUSH TO-TRIP button

to mechanically trip the circuit breaker. Trip, reset, and switch circuit breaker

ON several times. If mechanism does not reset each time the circuit breaker is

tripped, replace the circuit breaker.