11 of 14

WX-501-0537 • 01.22

Setting

Description

Module

Shows the name of the Click device.

Driver

Names the driver you are currently working with.

Description

Shows a description of the device being configured. This is only for your information and does not

affect the operation of the device.

Location

Displays the location of the device being configured. This is only for your information and does not

affect the operation of the device.

Serial Number

Displays the serial number of your device.

Firmware Version

Shows the version of firmware your device currently has installed. If Click Supervisor detects a

discrepancy between this version and the most current version it currently has access to, you will be

prompted to upgrade when you connect to the device.

Subnet ID

Shows the subnet ID number. This option is currently not available.

Device ID

Gives the ID number of the device being configured, which is used to identify the device when you

are connecting to it. By default, this number is the last five digits of the serial number, which can be

found under the About tab or on the barcode sticker on the bottom of the device. It is recommended

that you do not change this number unless another device on the network has the same ID number.

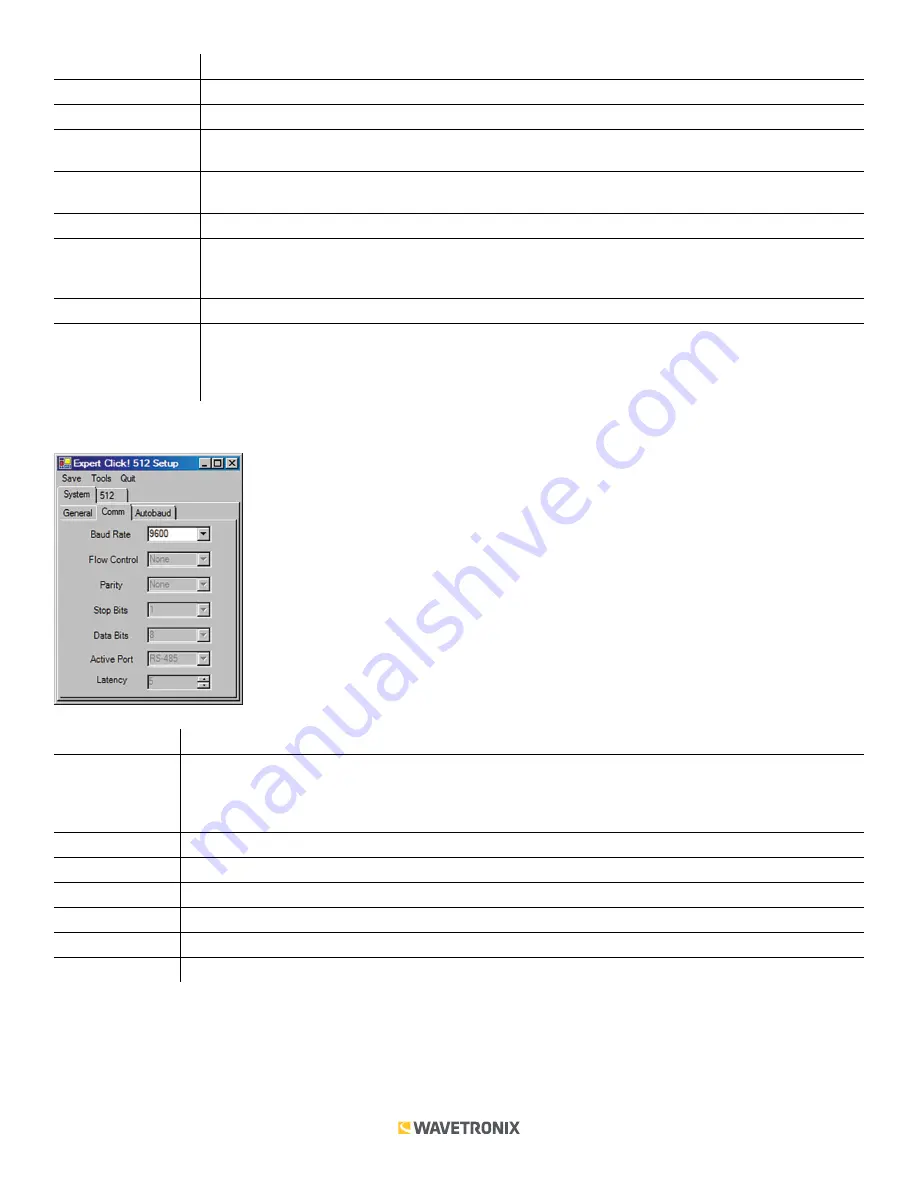

The

Comm

subtab allows you to configure how the Click device communicates (see the figure and table below).

Setting

Description

Baud Rate

Allows you to change the baud rate at which the device listens for data pushed from the SmartSensor

HD. It also changes the baud rate in serial convertor mode. It does not affect the baud rate for Click

Supervisor communications or data forwarding, which are always at 9600 bps. It does not affect the

baud rate of communications with a Click 104/112/114.

Flow Control

Is used for configuring hardware handshaking. This option is currently not available.

Parity

Allows you to set parity error checking. This option is currently not available.

Stop Bits

Allows you to set the number of stop bits. This option is currently not available.

Data Bits

Shows you the number of data bits being sent. This option cannot be changed.

Active Port

Indicates on which port you are communicating with the sensor. This option cannot be changed.

Latency

Indicates the latency between the sensor and the Click device. This option cannot be changed.

The

Autobaud

subtab allows you to configure how the device autobauds (see the figure and table below). As

none of these options can currently be changed, you would only use this tab if you needed to look at how the

device’s autobaud function is currently set up.