14

ENABLE THE QCL INSTRUMENT

Press the

Enable

button on the front panel. The button will

glow blue only when current is delivered to the load. There is

a standard 2-second delay before the button illuminates and

current flows.

VI SCAN

1. On the Control screen, press to access the VI

scan screen.

2. Press the

Current Start

value to select the current at

which to start the scan. Turn the

Adjustment

knob to

change it.

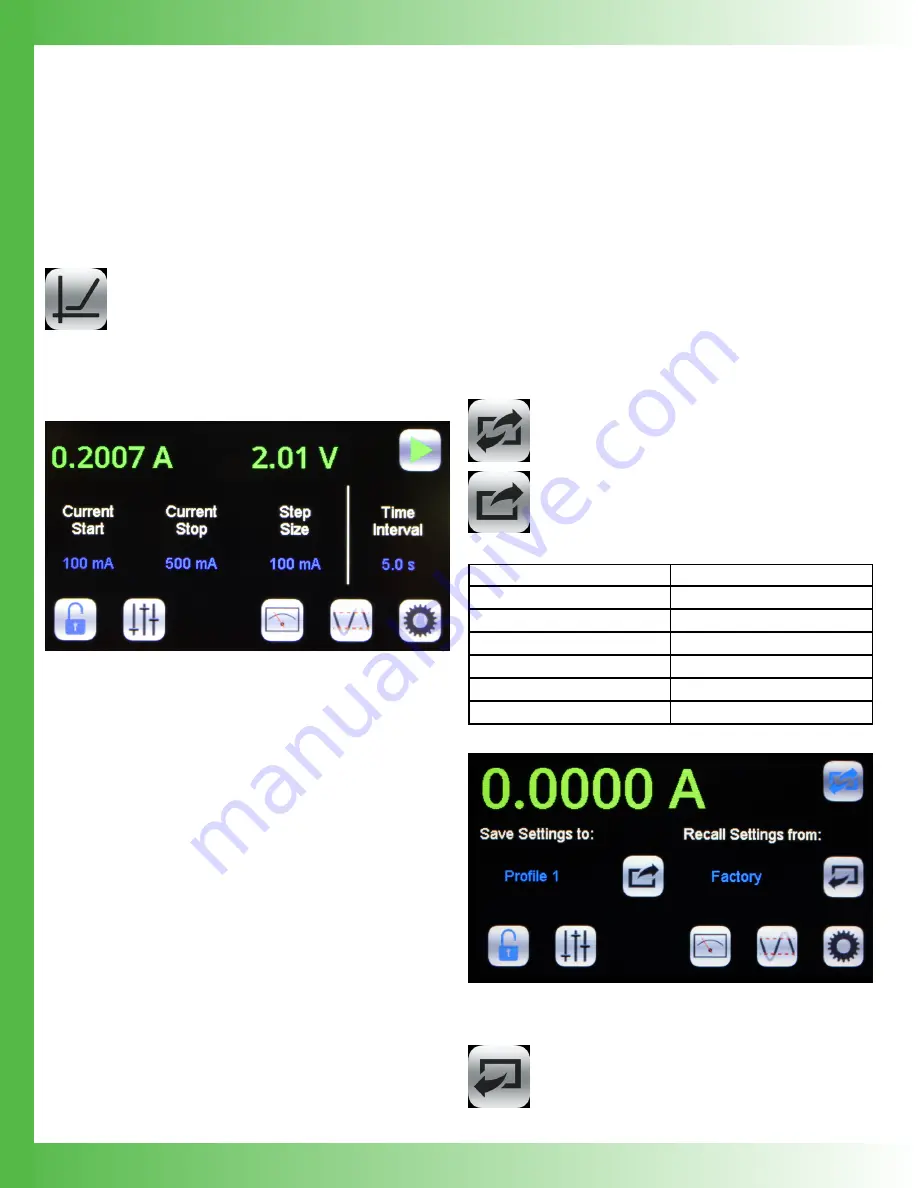

Figure 19. Scan Screen

3. Press the

Current Stop

value to select the current at

which to stop the scan.

4. Press the

Step Size

value to select the current interval at

which to take a measurement. The maximum interval is

10% of full scale. Minimum step is 1% of full scale.

5. Press the

Time Interval

value to select the amount of time

to allow the current to settle. For the best data accuracy,

use a Time Interval of 2 seconds or more. The minimum

time interval is 0.1 seconds.

6.

Insert the USB flash drive in the USB slot on the front

panel.

7. Press the green

Run

button to start the scan. When

finished, data is saved to the USB flash drive with

the filename

viscanxx.txt

, where xx starts at 00 and

increments.

8. To stop mid-scan, press the red

Stop

button to abort the

scan. Any data collected during the aborted scan is saved

to the USB flash drive.

NOTES:

•

The step interval time is approximate. In the scan files,

time intervals are slightly more than the step interval

indicated on the instrument. Each interval builds on the

previous one.

•

Should the Step Size interval not finish at the Stop Current,

the reading is still taken and recorded. For example,

if the Start Current is 250 mA and the Stop Current is

1.04 A with a Current Step of 250 mA, a reading is taken

at 1000 mA (1 A) and 1040 mA (1. 04 A) but not at 1250

mA (1.25 A).

• After a VI scan is completed, the output is disabled and

the setpoint is zeroed.

SAVE OR RECALL SETTINGS

Press to access the Save/Recall Screen.

Under

Save Settings to

, press the blue text

to toggle through the Profile options, select

one, and then press the

Save

icon.

The following variables are saved:

OPERATION SETTINGS

VI SCAN SETTINGS

Setpoint

VI Start Current

Current Limit

VI Stop Current

Max Supply Voltage

VI Step Size

Cable Resistance

VI Time Interval

Display Brightness

Beeper Status

Figure 20. Save / Recall Screen

Under

Recall Settings from

, press the

blue text to toggle through the saved Profile

options, and then press the

Recall

icon to

recall the saved settings. Select

Factory

to

restore the settings to the factory defaults.