ISOMIX HC-IM-DE-W-DE-10-2018-Rev1_enUS | Art. No. 10070436

9

EN

ENGLISH

6.2 Initial commissioning

All screw fittings must be checked and tightened if

necessary prior to installation and commissioning!

Torque:

• ¾” screw fittings 35 Nm

• 1” screw fittings 55 Nm

• 1

1/2

” screw fittings 130 Nm

1. Connect the control station to the pipe network.

2. Shut off the ball valves (using ball valves (15) supplied

with the heating circuit manifold or shut-off device fitted

by the customer).

3. Switch off the pump and close all of the heating circuits

on the distributor.

It is sufficient to close the valves in the return

collector of the heating circuit manifold with the

protection caps.

4. Fill the manifold and control station with hot water (in

accordance with VDI 2035):

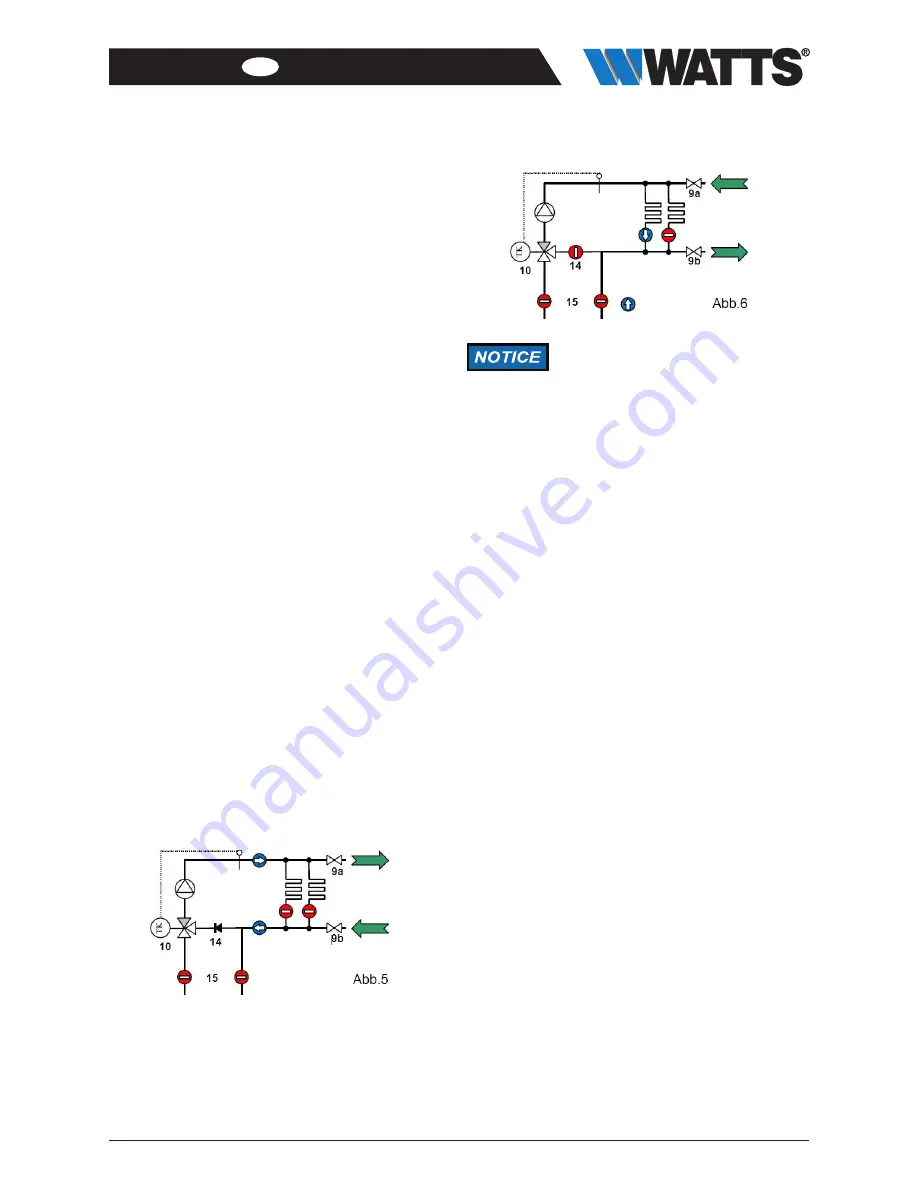

5. connect the filling hose to the fill and drain valve on the

return (5-9b) and the draining hose to the fill and drain

valve on the supply (5-9a).

Heating circuits are closed.

6. Open both fill and drain valves and fill the manifold and

control station until water comes out of the fill and drain

valve on the supply.

7. Close both fill and drain valves.

8. To fill and flush the heating circuits, connect the filling

hose to the supply fill and drain valve (6-9a) and the

emptying hose to the return fill and drain valve (6-9b).

9. Open the heating circuit to be flushed.

10. Open fill and drain valve and flush out the heating circuit

in the direction of flow until the air and any contamination

has been removed from the circuit completely.

The non-return valve (14) in the mixer bypass prevents

any short circuit when flushing.

11. Repeat the process for all the heating circuits.

Flushing is permitted only in the direction

of flow of the heating circuits, i.e. the

water must enter through the flow

manifold and come out of the return!

The drain must always be open, as

otherwise the high water pressure could

damage the heating system.

The instructions on flushing in the

operating manual for the heating circuit

manifold must also be observed.