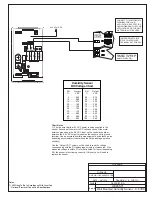

General Notes

FILENAME

DATE:

B. CREWS

DESCRIPTION:

PAGE

DRAWN BY:

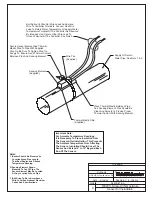

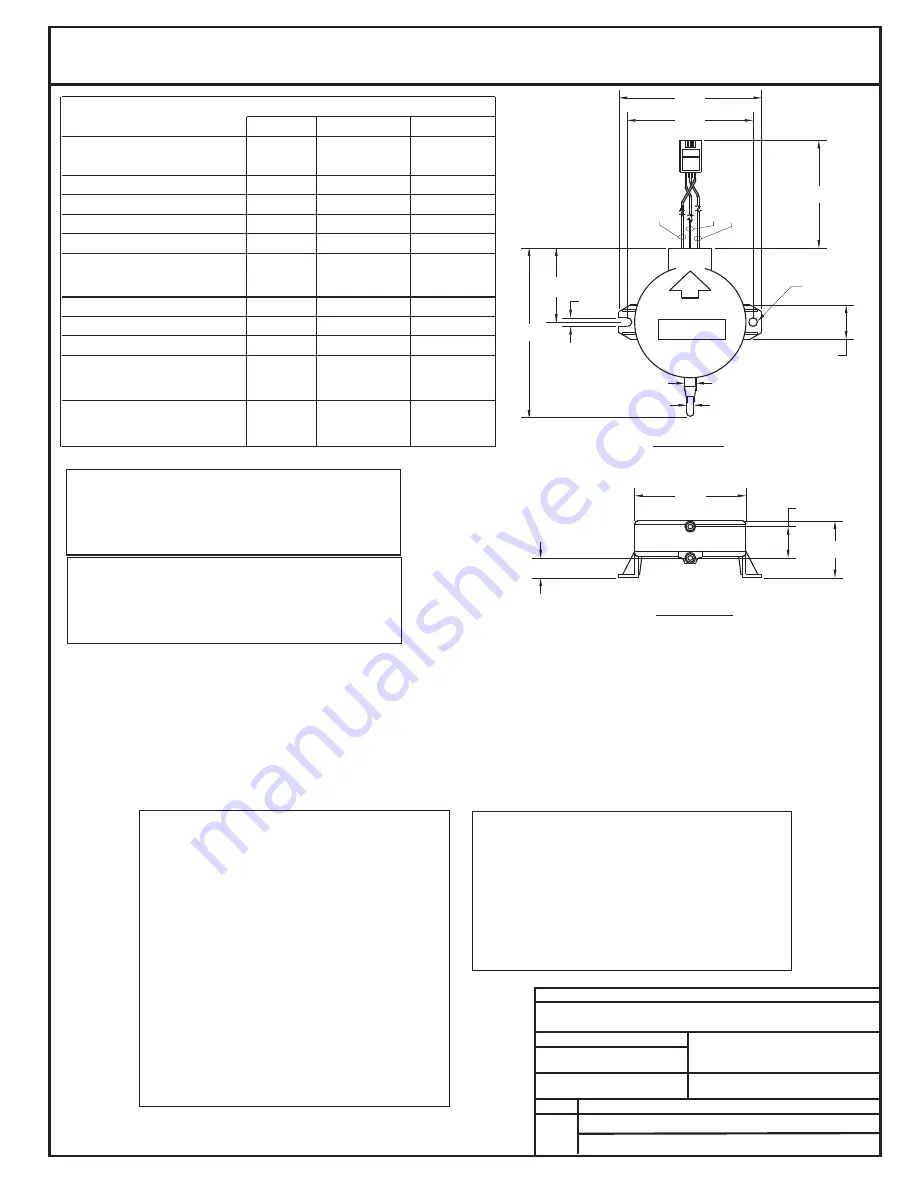

Pressure Sensor

1

JOB NAME

2.)All Wiring To Be In Accordance With Local And

National Electrical Codes And Specifications.

08/19/08

G-OE271TRAN1.CDR

OE271

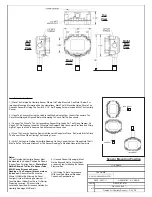

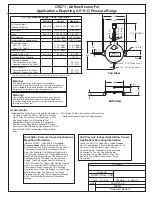

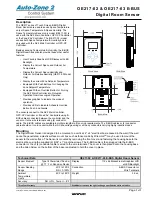

Top View

Side View

OUT

IN

GND

UP

(-)LO

0.35"

0.55"

1.00"

2.20"

0.15" DIA.

0.15"

2.94"

2.50"

0.125" (1/8" Tubing Conn.)

0.200" (3/16" Tubing Conn.)

1.95"

0.60"

12.0" APPROX.

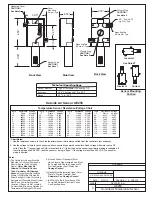

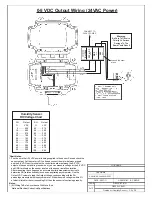

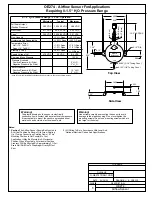

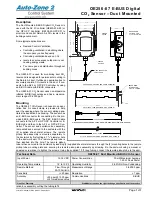

Full Scale Output

(Positive Pressure)

Null Offset

Span*

Minimum

Typical

Maximum

Hystereisis And Repeatability

Temperature Error

Null +10 To 40 C

°

°

Stability (1 Year)

Supply Voltage (Vs)

Pressure Overload

Burst Pressure

Positive Pressure (Hi Side)

Negative Pressure (Lo Side)

Positive Pressure (Hi Side)

Negative Pressure (Lo Side)

Non-Linearity

Span +10 To 40 C

°

°

Common Mode Pressure

0-5“ H O Pressure Range - 5 VDC Operation

2

3.92 VDC

0.17 VDC

0.2-0.3 VDC

0.33 VDC

3.59 VDC

3.91 VDC

±0

.05 % Span

4.75 VDC

5.0 VDC

8.0 VDC

15 PSI

25“ H O

2

50“ H O

2

15“ H O

2

25“ H O

2

4.08 VDC

3.95-4.05 VDC

3.65-3.85 VDC

±0

.3 % Span

±0

.5 % Span

±0

.03 % Span

±

1.0 % Span

±

0.5 % Span

±

1.0 % Span

±

1.5 % Span

±

1.5 % Span

*Span Is The Algebraic Difference Between End Points (Null Offset And Full Scale Output)

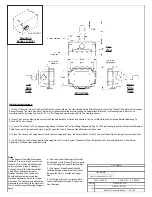

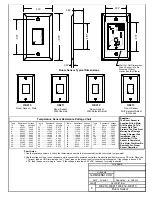

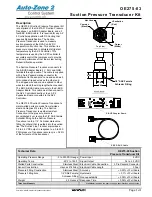

The plastic housing on the sensor is electrically

conductive. Avoid contact with any electrical components.

It is acceptable to mount the sensor on grounded sheet

metal such as ductwork, electrical panels, etc.

Use extreme care when mounting the sensor to avoid

damage to the plastic housing. Do not overtighten the

mounting screws! Do not use mounting screws which are

too large for the holes!

Warning!

Warning!

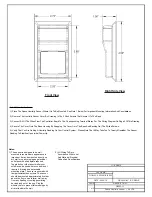

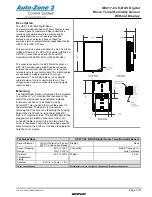

1.)

The Airflow Sensor Should Be Mounted In

A Vertical Position As Shown With Arrow Pointing

Up. ( Tubing Connections Pointing Down). If This

Mounting Position Is Not Possible In Your

Application, It May Be Mounted In A Horizontal

Position. When Mounted In A Horizontal Position

Accuracy Will Be Affected By Approximately 2% Full

Scale Null Shift Due To Diaphragm Gravity Effect

Error.

Caution:

1.29"

OUT

(Black)

GND

(Green)

IN

(Red)

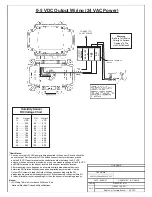

OE271

S.P. Sensor

OE271 -

For

Applications

Requiring 0-5“ H O Pressure Range

2

Airflow Sensor

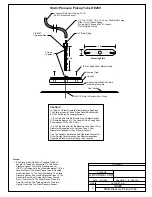

When The OE271 Is Used As A Duct

It May Be Mounted To The

Ductwork Near The Static Pressure Pickup Tube. If

The Sensor Is Mounted In This Manner, Away

From The Controller, The Modular Plug Must Be

Cut Off And 3-conductor 24 Gauge Minimum Wire

Must Be Butt Spliced Between The Sensor And

The Modular Plug To Extend The Sensor Wire

Length. Total Wire Length Should Not Exceed

100Ft. If Desired The Sensor May Also Be Located

Near The Controller, With The Modular Plug On

The Sensor Directly Connected To The Mating

Controller Jack. When This Method Is Used Tubing

Must Be Run From The Sensor To The Static

Pressure Pickup Tube. Tubing Should Not Exceed

250 Ft. And Must Be Continuous Without Any

Splices.

Static

Pressure Sensor

When The OE271 Is Used As An Airflow

For VAV Applications It Should Be Mounted In The

VAV Box Control Enclosure Near The Box

Controller Board. The Modular Plug should be

Connected To The VAV Controller Board

Connection. Tubing Must Be Run From The

Sensor to The Airflow Pickup Probe Tubing

Connection.

Sensor

Duct Static Pressure Sensor Applications

Mounting Information

VAV Pressure Independent Airflow Sensor

Applications Mounting Information