WaterFurnace works continually to improve its products. As a result, the design and specifi cations of each product at the time of order may be changed without notice. Please contact WaterFurnace at 1-888-929-2837 for latest design and

specifi cations. Purchaser’s approval of this data set signifi es that the equipment is acceptable under the provisions of the job specifi cation. Statements and other information contained herein are not express warranties and do not form the

basis of any bargain between the parties, but are merely WaterFurnace’s opinion or commendation of its products. The latest version of this document is available at www.waterfurnace.com.

Contractor: P.O.:

Engineer:

Project Name:

Unit Tag:

SD2552WNB 09/16

29

Page _____ of _____

ENVISION

2

NKW

REVERSIBLE CHILLER - 50Hz

Engineering Guide Specifi cations cont.

Heat Exchangers:

1.

The water to refrigerant heat exchangers shall be

dual circuit, copper-brazed 316 stainless steel channel

plates, capable of withstanding 4.5MPa psig working

pressure on the refrigerant side and 3.1MPa psig on

the water side. Refrigerant circuits are separate with a

common water supply. This provides optimal part load

efficiency compared to using two single circuit heat

exchangers. Heat exchangers are designed to work as

an evaporator and condenser.

2.

Heat exchangers are covered with 19mm closed-cell

insulation on sizes 030-060 and 25mm closed-cell

insulation on sizes 090-150.

3.

Water line connections attached to the heat

exchangers are groove type are factory installed

with groove coupling and steel pipe nipple. Pipe

nipple is insulated and comes with 1/4" NPT pressure/

temperature port.

Refrigerant Components:

1.

Unit shall utilize R-410A refrigerant type. All system

components shall be rated to appropriate UL standards

to handle maximum system pressure.

2.

Factory charged, sealed system contains optimal

refrigerant quantity.

3.

Each refrigerant circuit shall utilize a thermostatic

expansion valve (TXV) with stainless steel sensing bulb

and laser welded diaphragm. TXV will control adequate

superheat over the stated operating range as indicated

in submittal data.

4.

Bidirectional, liquid line filter driers are to be factory

installed to provide additional system cleanliness.

5.

Factory installed service ports for high and low

pressure readings.

6.

Optional factory installed pressure gauges mounted

below control panel aid in field diagnostics and

reduces need for technician applied gauges.

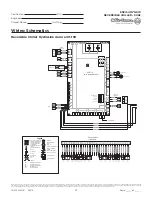

Control Panel

1.

Factory installed, wired, and functionally tested at

factory before shipment.

2.

Single-point power connection to non-fused, or fused

rotary-type disconnect in control panel.

3.

Factory installed, DIN mounted CUBEFuse with Class J

rating wired for protection of each compressor.

4.

Low voltage, emergency stop button factory wired and

mounted to control panel service door.

5.

Factory mounted class 2, control power transformer

provides nominal 24 VAC low voltage power supply.

Primary to transformer is protected by Class CC fuses.

6.

High pressure cut out set at 4.1MPa with manual reset.

7.

Low pressure cut out set at 275kPa with manual reset.

8.

Unit shall have phase loss/reversal for

compressor protection.

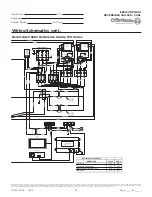

Controls:

1.

The unit shall be controlled using a microprocessor

which sequences all functions and modes of operations.

2.

Units shall be capable to communicate thru standard

DDC protocols such as N2, Lon, and BACnet (MS/TP @

19,200 Baud Rate).

3.

Standalone, non-communicating units are also

available that will operate with thermostat, mechanical,

or electronic signals. Temperature set mode is capable

of controlling to leaving/entering load temperature.

4.

The control system shall have the following features:

•

Anti-short cycle time delay of 5 minutes on

compressor operation.

•

Random start on power up mode

•

Low voltage protection

•

High voltage protection

•

Unit shut down on high or low refrigerant pressures

•

Unit shut down for freeze detection

•

Source and Load heat exchanger freeze detection

setpoint selectable for water or antifreeze

•

Automatic intelligent reset

5.

A 4 x 20 digit backlit LCD to display the following:

•

Entering and leaving water temperatures

•

High pressure, low pressure, low voltage, high

voltage, freeze detection setpoint, and control status

•

The low pressure shall not be monitored for

the first 120 seconds after a compressor start

command to prevent nuisance safety trips

•

Remote fault indication on the thermostat

•

An accessory relay output tied to each compressor

selectable for normally open or normally closed

6. Control

Inputs:

• Start/Stop

• Lead/Lag

•

Freeze detection set point for load/source

•

Water temperature set point

• Control

Outputs:

• Status:

Cooling/Heating/On/Off

•

Load Side Supply and Return Temperatures

•

Source Side Supply and Return Temperatures

•

Evaporator Entering Refrigerant Temperatures

•

Condenser Leaving Refrigerant Temperatures

Accessories:

1.

Additional Items Not Listed Previously:

•

Compressor sound blankets to reduce sound

power level of unit.

•

Flow switch to monitor the units presence of flow.

2.

Flow Proving Switch

•

A flow proving switch shall be available utilizing

high reliability flow sensing technology.