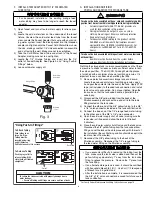

How to Sanitize the Storage Tank and Filtration System

Sanitizing the storage tank generally requires:

•

Common household bleach (5.25% non-scented)

•

Eye dropper or plastic oral syringe

1) Close the cold water feed valve and lift up on the faucet

handle to empty the water in the storage tank. It should

feel light when empty.

2) Disconnect the 3/8” yellow tubing (system tank) from the

ball valve on top of the storage tank.

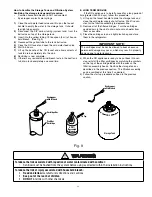

3) Insert into the yellow tubing 1/2 teaspoon (3 ml) of house-

hold bleach. (See Fig 9)

4) Reconnect the yellow tube to the tank ball valve.

5) Close the RO faucet and open the cold water feed valve.

6) Wait 4-5 hours.

7) Lift up the handle of the RO faucet and allow contents of

tank to drain completely into the sink.

8) Sanitizing is now complete.

9) If there is any residual chlorine/bleach taste in the next tank

full, drain tank completely a second time.

E. LONG TERM NON-USE

If the RO appliance is to be left unused for a long period of

time (greater than 30 days), follow this procedure:

1) Lift up on the faucet handle to drain the storage tank and

close the cold water supply shut off valve. Wait five min-

utes for the filtration assembly to depressurize.

2) Remove all of the filter cartridges. Turn the cartridges

upside down in the sink to drain out as much water from

them as possible.

3) Place the cartridges in an air tight plastic bag and store

them in the refrigerator.

IMPORTANT NOTE:

The cartridges must be not be allowed to freeze because

permanent damage may occur, which may result in property

damage due to water leakage.

4) When the RO appliance is ready to be put back into ser-

vice, reinstall the filter cartridges by matching the symbols

on the top of the cartridge labels with the ones on the

filtration assembly heads. Sanitize the storage tank as

described in the previous section. The filtration assembly

can be sanitized at this time if so desired.

5) Follow the start up procedure outlined in the previous

section.

15

Eyedropper

with Bleach

Prefilter

Cartridge

Cartridge Ear

1/2 Tsp.

5.25%

Unscented

Bleach

Eyedropper

with Bleach

Storage Tank

Fig. 9

To reduce the risk associated with ingestion of water contaminated with sanitizer:

• Sanitizer must be flushed from the system before using as directed within the installation instructions.

To reduce the risk of injury associated with household bleach:

• Read and follow

manufacturers directions and cautions

• Keep out of the reach of children

• DO NOT

intermix with other chemicals