D e t e c t i o n

PDM PRO CO

2

Sustainable Single Gas Detector

User Manual

14

D e t e c t i o n

5.1.1. READ

The “Read” button (upper-left side first icon) allows a user to retrieve the stored data.

5.1.2 WRITE

The “Write” button (upper-left side second icon) has one of the most important role in this software interface.

Because every single and each configured or customized settings will be saved by clicking “Write” button. When a

user configures the instrument`s settings, “Write” button will be clicked and message will pop-up. Click “Yes”.

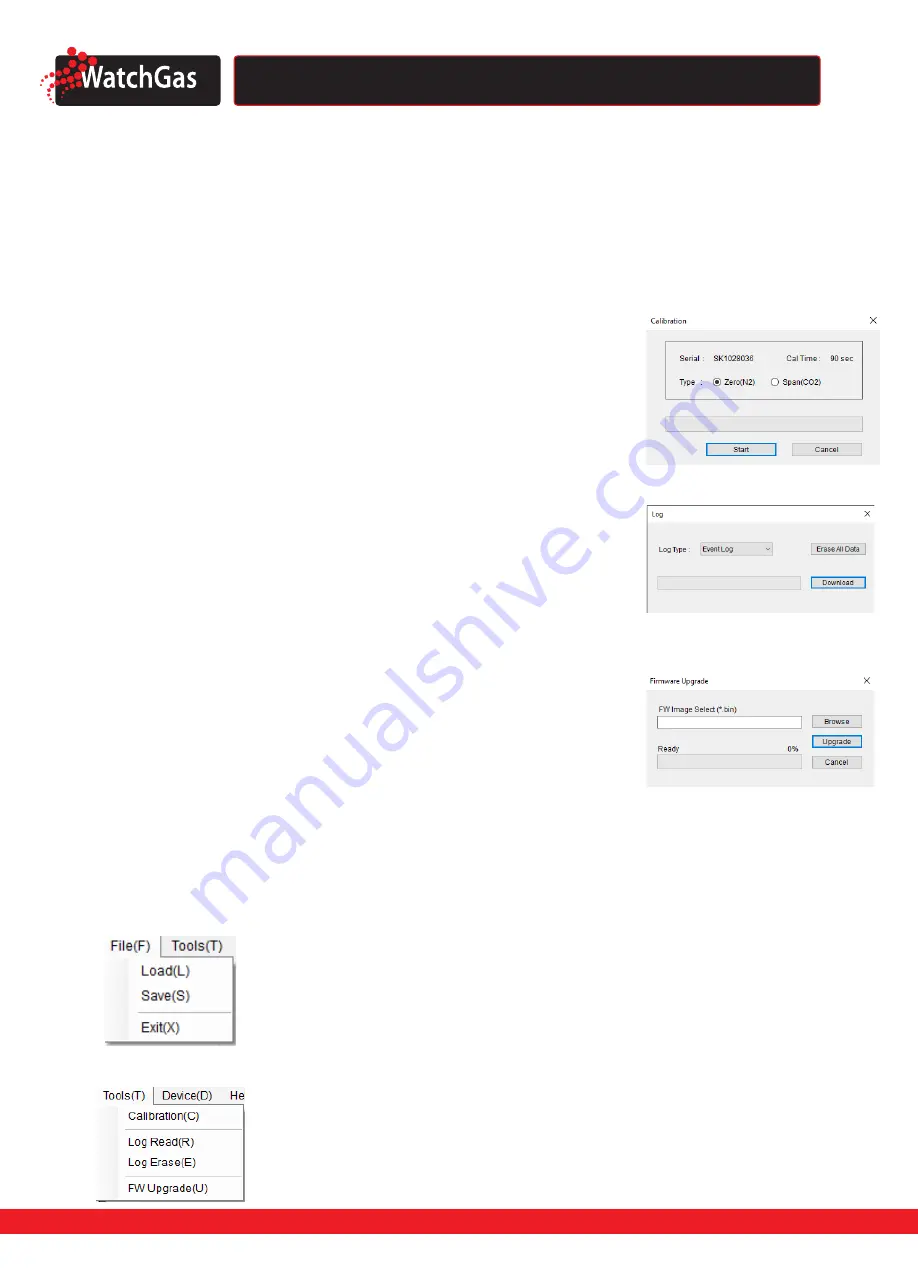

5.1.3 CALIBRATION

To perform the calibration using software, follow the below:

1. Connect the unit to the PC using instrument`s USB

2. Plug the calibration cap and connect with N

2

or CO

2

gas cylinder.

3. Open the software and click “Calibration” (middle-left side icon) and wizard will

come up

4. Choose the calibration gas type and click “Start” with releasing the gas from the

cylinder.

5. The zero(N

2

) and span(CO

2

) calibration takes 90 seconds.

5.1.4 LOG

All recent 30 events and 64.000 gas readings will be stored in the device and will

be automatically erases one by one from the earliest logs when new event occurs.

There are two types of event logs, “Event Log” and “Event + Data log” are available

to download. Choose the log and click “Download” button. The log files will be

downloaded and created by unit`s Serial number and will be in “.csv” format. However,

clicking “Erase” button will clear all the logs from the storage of device and cannot be

recovered.

5.1.5 UPGRADE (FIRMWARE)

1. To upgrade the latest firmware version of the PDM PRO CO₂, follow the below:

2. Click “Browse” button and navigate to the firmware location

3. Choose the firmware and click the “Open” button

4. Click “Write” to begin upgrading process

5. When upgrade is finished, power off the device and turn it on

6. The “F-UP” ->“boot” message will come up and upgrade is complete

Note:

Pressing “Cancel” button during the upgrading process will cancel and close the Firmware Upgrade Wizard

5.2 WINDOW MENU

5.2.1 MENU - FILE (F)

5.2.2 MENU - TOOLS (T)

•

Load(L)

Load the installed settings

•

Save(S)

Save the current settings

•

Exit(X)

Finish the work and end the program (close the tap)

•

Calibration(C

) Open the calibration window to start calibration process

•

Log Read(R)

Retrieve and save the log events

•

Log Erase(E)

C lean all the logs from the storage (erased logs cannot be recove-

red)

•

FW Upgrade(U)

Open the firmware upgrade window to start upgrading process