THIS DISPOSER UTILIZES ANTI-JAM SWIVEL IMPELLERS THAT MAKE A CLICKING SOUND AS THEY

SWING INTO PLACE. THIS INDICATES NORMAL OPERATION.

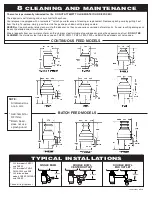

BATCH FEED MODELS:

LARGE

SMALL

MEDIUM

6

OPERATING INSTRUCTIONS

6A

6B

6C

6D

CONNECTING DISPOSER TO 3-BOLT MOUNT ASSEMBLY

A.

Remove sink stopper. Turn on

cold water using a medium flow.

B.

Turn switch to ON position; your

motor is turning at full speed

and ready to use.

C.

Scrape in food waste. Down the

drain go table scraps, peelings,

cobs, rinds, seeds, pits, bones

and coffee grounds. To speed up

food waste disposal, cut or

break up large bones, rinds and

cobs. Large bones and fibrous

husks require considerable

grinding time and are more

easily thrown away with other

trash. Do not be alarmed that

the disposer slows down while

grinding. The disposer is actually

increasing torque (grinding

power) and is operating under

normal conditions.

D.

Before turning disposer off, let

water and disposer run for

approximately 25 seconds after

shredding stops. This assures

that all waste is thoroughly

flushed through trap and drain.

E.

It is not recommended to use

hot water while running

disposer. Cold water will keep

food waste and fats solid so dis-

poser can flush away particles.

F.

PM4 model is designed for

intermittent usage only and is

not rated for continuous

commercial usage.

A.

Remove sink stopper and turn

on a medium flow of cold

water (see 6A).

B.

Scrape in food waste. Down

the drain go table scraps,

vegetable peelings, cobs, rinds,

pits, bones and coffee grounds

(see 6B).

C.

Insert stopper to start disposer

(see 6C). One of the two

small slots in stopper base

must line up with switch plunger

inside the neck of the disposer.

Push down firmly. Lift stopper to

shut disposer off.

D.

Run disposer for 25 seconds

after shredding stops.

This assures that all waste is

thoroughly flushed through trap

and drain.

E.

To fill sink, insert stopper so that

largest slot lines up with switch

plunger (see 6D). Stopper can

now be pushed down to seal

sink without actuating disposer.

When medium sized slot (see 6C)

in stopper base is lined up with

the switch plunger, water can

drain, but tableware, etc.,

cannot be accidentally dropped

into disposer.

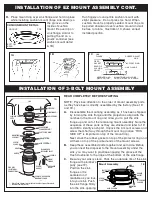

A.

Press firmly around the Hush Cushion® to ensure

it is engaged with the neck of the disposer.

B.

Lubricate the top inside lip of the rubber Hush

Cushion® with a liquid soap.

C.

Line up discharge elbow of disposer with trap

under mounting assembly. Guide disposer up and

engage the groove of the Hush Cushion® around

the ridge at the bottom of the sink flange (see 5E

& refer back to 3B). While still supporting the dis-

poser, tighten the screw-clamp around Hush

Cushion®. The disposer will now hang by itself.

D.

If you need to turn the disposer make sure the sink

flange does not turn. It will break the seal created

when installed. Go back to steps 5A and 5B.

IMPORTANT – PLEASE READ

Do not remove clamp from Hush Cushion® or

Hush Cushion® from hopper. Both parts are factory

installed and installation ready.

Lubricate top angled surface of

rubber Hush Cushion® with liquid

soap prior to engaging disposer

to sink flange. Fit Hush Cushion®

lip into sink flange groove using a

slight rocking motion. Tighten

clamp (see 5F).

5F

SINK FLANGE

CLAMP

HUSH CUSHION®

TOP ANGLED

SURFACE

HUSH

CUSHION®

5E

SINK

FLANGE

GROOVE

CLAMP

HOPPER