This is quite acceptable providing that:

The heating wires are spaced at least 50mm

apart at all times.

The heating wires never cross.

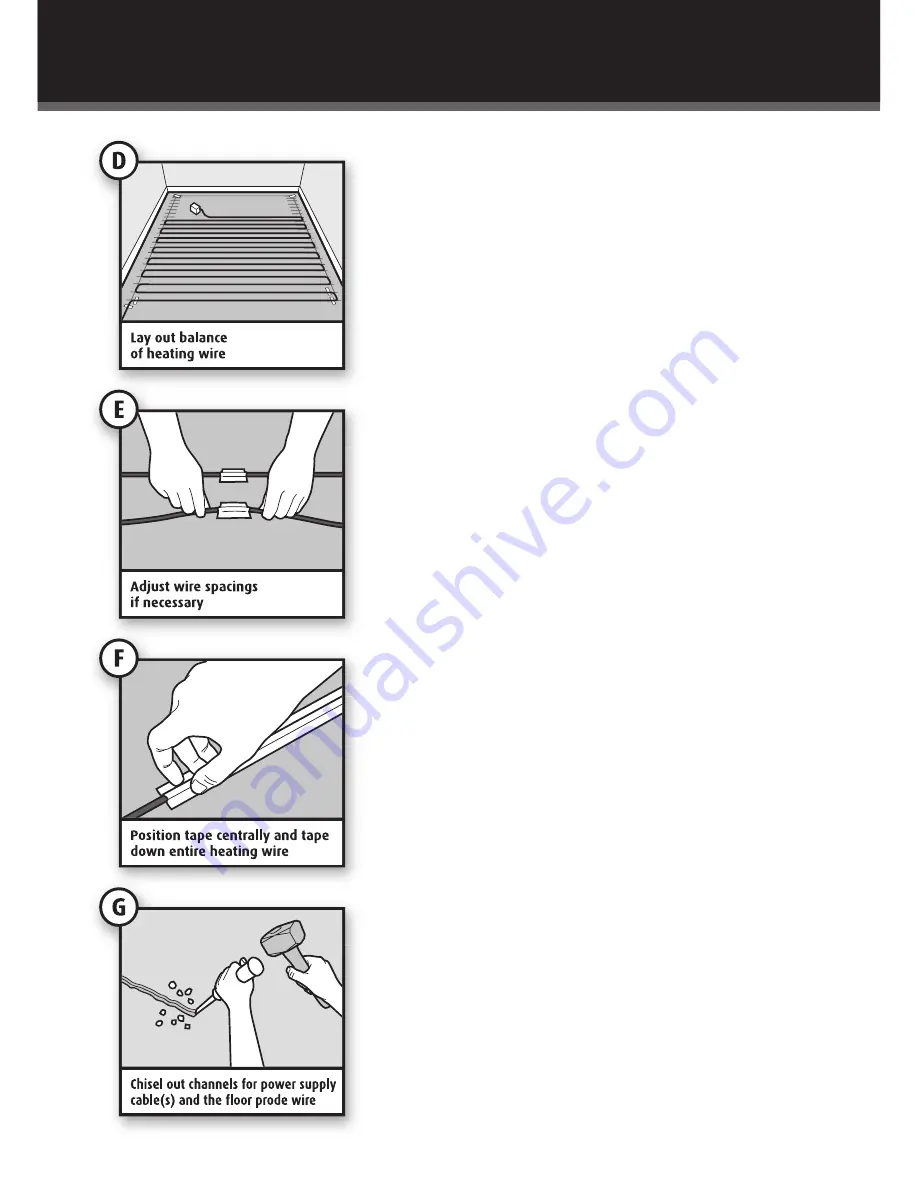

Once the heating wire layout has been completed, the

entire length of the heating wire should be taped to

the floor.

Ensure the greatest possible adhesion, with the minimum

of trapped air space beneath the taped wire. As you

apply the tape, gently tighten the heating wire from the

ends to ensure it is straight.

The wire should be located in the centre of the tape

to provide maximum protection from the tiler’s trowel.

If the tape is not completely covering the wire at any

point, apply another layer of tape to provide

additional protection.

After applying a length of tape, run your forefinger and

thumb along the length of the wire, gently squeezing

the wire to remove any air space between the wire

and the tape.

Depending on the requirements of the tiler, it may be

necessary to chisel out or "chase" short channels in the

subfloor to minimise the increased height presented by

the power cable, the end joint and the floor probe wire.

Before chiselling the area, ensure that the heating wire

and power supply cable are out of the way. Fit the power

supply cable into the channels and secure with fixing tape.

Remove all debris and chippings from the floor. Unless

the floor is being tiled immediately, cover the floor with

hardboard or cardboard to protect the heating wire.

Note:

the main joint and end cap must be covered by adhesive and tile.

Do not tape over these joints as air pockets can occur and cause the joint

to fail due to overheating.

13

Summary of Contents for DWS300

Page 16: ...Notes 16 ...

Page 17: ......