4.5

Air Vents

On the system boiler an automatic air vent complete with its own check valve is fitted

to the top of the boiler heat exchanger. It is recommended that an air vent is fitted at

the highest point in the system. However where the pipework comes off the boiler and

drops down an automatic airvent should be fitted to the top of the boiler.

4.6

Drain Cock

Drain cock(s) should be fitted to the lowest points in the system to enable the system

to be fully drained. On the system boiler a drain cock has been fitted to the system

boiler heat exchanger.

4.7

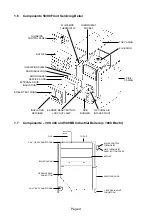

Expansion Vessels

Refer to BS 7074: part 1 or BS 5449 for details of the pressure vessel sizing. The

values given in the table are for a total system values which includes the primary water

capacity. On the system boiler a 12 litre expansion vessel charged to 0.5 bar is supplied.

This can accommodate a maximum system volume of approximately 150 litres. If this

volume is exceeded an additional vessel will be required.

0.5

2.1

4.2

6.3

8.3

10.5

12.5

14.6

16.7

18.7

20.8

22.9

25.0

1.0

2.7

5.4

8.2

10.9

13.6

16.3

19.1

21.8

24.5

27.2

30.0

32.7

1.5

3.9

7.8

11.7

15.6

19.5

23.4

27.3

31.2

35.1

39.0

42.9

46.8

25

50

75

100

125

150

175

200

225

250

275

300

INITIAL

CHARGE

TOTAL

SYSTEM

VOLUME

VESSEL VOLUMES

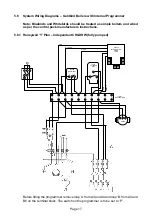

4.8

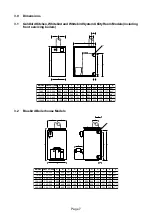

System Filling

Water loss from a sealed system, as indicated by a reduction in pressure on the pressure

gauge, may be made up through a filling loop, however the cause of the water loss

should be fully investigated and corrected.

After filling, vent all air from the system. Ensure the caps on the automatic air vents are

loose, bleed the circulating pump and disconnect the temporary filling loop.

As standard, a filling point complete with a filling loop has been included within the

system boiler. A system pressure, when cold, of 1 bar is recommended.

4.9

System Pressure

The pressure relief discharge shall be positioned away from any electrical components.

No other valves should be positioned between the relief valve and the discharge, and

the discharge pipes should not be used for any other purposes. The discharge pipe

must be plumbed to an external drain in a position where the discharge can be seen

but cannot cause any injury or damage.

Where there is a catastrophic loss of water from the system the boiler thermostats

may fail to operate which would result in serious damage to the appliance. To prevent

this it is recommended that a low pressure cut out switch set at 0.2 bar is fitted to the

system and wired in series with the boiler thermostats.

Page 13