26

1.

Position the tractor / wood chipper at the work

site.

2.

Set the tractor brake and block / chock the

wheels.

3.

Lower the chipper, ensure that the machine is

resting on the ground and is level and stable.

4.

All models except the BX32 Series: While

holding the feed hopper, release the latch pin

from the feed hopper pin tab, and carefully

lower the feed hopper.

5.

With the feed table in position, engage the

spring loaded latch pin to secure the hopper.

6.

Turn the discharge chute to the desired

position and adjust the deflector as required.

4�8 MACHINE SET-UP

Follow this procedure to prepare and set-up the machine at the work site: the chipper is attached to the

tractor 3 point hitch, PTO driveline is installed and hydraulics are connected.

IMPORTANT

Position the machine so the

prevailing wind/breeze blows the

exhaust gases/fumes away from

the operator's station.

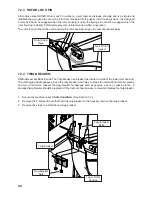

Feed Hopper Lock

Pin

IMPORTANT

The chipper must be resting on

the ground during operation, using

the chipper while raised up off the

ground is dangerous and will result

in damage to the machine.

4�8�1 BX52S ADJUSTABLE SKI HEIGHT

IMPORTANT

Do not use the ski to adjust for

user height, damage to the PTO

may occur if the angle becomes

too severe

Z94242

Note:

When lowering the

feed hopper, be aware of

a pinch point between the

hopper and the sub chute.

The ski can be adjusted up to 6.0" if required to

help align the PTO when attaching your chipper

to the tractor. The PTO should be as level as

possible when the chipper is in the lowered

(working) position.

1.

Raise the chipper.

2.

Loosen the 4 nuts and bolts.

3.

Lower the ski to the best position for the PTO

connection.

4.

Tighten the nuts and bolts according to the

Torque Chart (at the back of the manual).