8

BA201

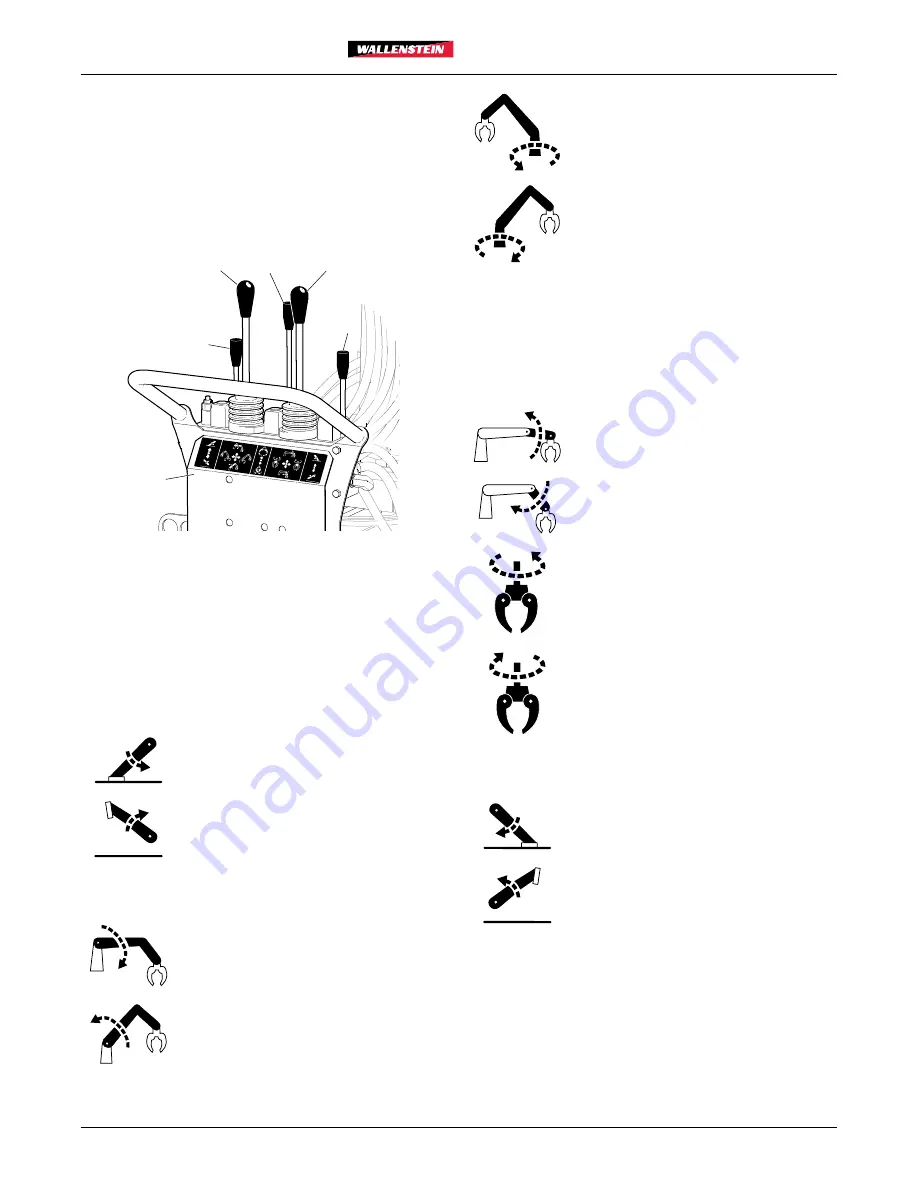

Controls

The main control valve has five control levers. The two outer

levers control the position of the stabilizers, and the other three

levers operate the main boom, dipper boom, and grapple.

With the

BA201 Backhoe Kit

installed, bucket curl-in and

curl-out is performed with the left-to-right grapple rotate control

lever (4). Grapple open/close lever (3) is not used.

01623

1

2

3

4

5

6

Fig. 9 –

Main Directional Control Valve

1. Left-hand Stabilizer Raise/Lower

2. Main Boom Raise/Lower, Rotate

3. (Not used with Backhoe Kit)

4. Dipper Boom Raise/Lower, Bucket Curl-in/Curl-out

5. Right-hand Stabilizer Raise/Lower

6. Control Valve Function Decal

1. Left-hand Stabilizer

Stabilizer lower

–push the lever forward to

lower the stabilizer.

Stabilizer raise

–pull the lever back to raise

the stabilizer.

2. Main Boom Raise/Lower, Rotate

Main boom lower

–push the lever forward to

lower the main boom.

Main boom raise

–pull the lever back to raise

the main boom.

Main boom rotate left

–push the lever

to the left to rotate the main boom

counterclockwise .

Main boom rotate right

–push the lever to the

right to rotate the main boom clockwise.

3. Not used with Backhoe Kit

4. Dipper Boom Raise/Lower, Bucket Curl-in,

Curl-out

Dipper boom raise

–push the lever forward to

raise the dipper boom.

Dipper boom lower

–pull the lever back to

raise the dipper boom.

Bucket Curl-in

–push the lever left to curl the

bucket in.

Bucket Curl-out

–push the lever to curl the

bucket in.

5. Right-hand Stabilizer

Stabilizer lower

–push the lever forward to

lower the stabilizer.

Stabilizer raise

–pull the lever back to raise

the stabilizer.

Summary of Contents for BA201

Page 15: ...WallensteinEquipment com...