Maintenance Instructions

ADJUSTMENTS

77

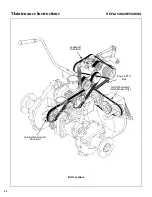

Blade Brake Band Adjustment

NOTE: The length of the actuator rod is adjusted

by disconnecting the bottom clevis and shortening

or lengthening accordingly. The standard pre-set

length of the actuator rod is set at the factory at

8-1/4 in. (209 mm).

Brake Actuator Rod Adjustment

2.

After adjustments are complete, check blade

brake action as described in CHECKING/SER-

VICING the Blade Brake Action in this section.

If blades do not stop within five (5) seconds,

check the following:

a.

Recheck 1/8 in. (3 mm) gap between stop

block and chassis.

b.

Make sure clutch and brake linkage are

working freely (no binding).

c.

Check the brake band lining.

d.

Check the brake drum on the pulley. If

excessive wear is present, it will be neces-

sary to replace worn parts.

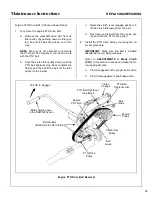

Transmission Control

IMPORTANT: The proper adjustment of the trans-

mission control stops is essential for efficient oper-

ation and life of the transmission. These stops are

properly adjusted at the factory and should only re-

quire readjustment if the transmission or related

control linkage is removed or changed.

NOTE: It would not be unusual for a new machine,

after initial 5 or 10 hours of operation, to begin to not

travel straight (this is due to the break-in of the

transmissions). In this case, proceed to

Straight

Ground Travel Adjustment - Step 4

.

IMPORTANT: The following adjustment proce-

dures are sequential. Check and adjust each func-

tion in the order given.

Set Forward Travel Limit (Stop) - Step 1

1.

Move the Forward Speed Control (FSC) lever to

the most FORWARD position.

2.

Check clearance of the RH and LH steering le-

ver actuator arms with the frame and adjust for-

ward stop bolt so each lever clears the frame

by at least 1/16 in. (1.6 mm). Clearance of the

arm to the frame should be checked while ap-

plying pressure back on the arm to remove

any slack in the linkage.

Blade Clutch

Idler Pulley

1/8 in.

(3 mm)

PTO Belt Tightener

Chassis

Stop Block

8-1/4 in.

(209 mm)

Bottom

Clevis

Locknuts