H37i

Maintenance Instructions

Checking and Servicing

59

CHECKING/SERVICING

DANGER

To prevent accidental starting of the engine

when servicing or adjusting the machine,

remove the key from the ignition switch

and disconnect the spark plug wires.

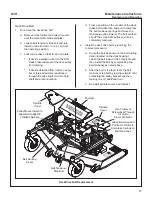

Security of Air Cleaner System

NOTE:

The following inspection is

only an exter-

nal inspection

and should be done without

“dis-

turbing”

the filtration components.

On a daily basis, visually inspect the external

condition of the engine air cleaner system. The

following items should be inspected:

1. Check the Briggs & Stratton air cleaner canis-

ter for damage. Make sure the cover is in

place and the cover latches are secure—do

not run the engine without the air cleaner

cover in place and secure.

2. Inspect the air intake hose (into the engine) for

cracks, nicks, cuts, ect., and check the hose

clamps for tightness.

Battery

The battery comes sealed and is maintenance-

free, so the electrolyte level will not need to be

checked or filled.

IMPORTANT:

Make sure battery is securely

mounted in the frame. A loose battery may cause

damage to the case resulting in acid leakage and

severe damage to the machine. A hazard may be

created by damage to critical working parts and

safety systems.

CAUTION

Important Battery Service, Installation, and

Charging Tips for Electronic Fuel Injection

Engines:

●

Do not allow the battery cables to touch

opposing terminals. When connecting

battery cables attach the positive (+)

cable to positive (+) battery terminal

first, followed by negative (-) cable to

negative (-) battery terminal.

●

Never start the engine when the cables

are loose or poorly connected to the

battery terminals.

●

Never disconnect battery while engine

is running.

●

Never use a quick battery charger to

start the engine.

●

Never “jump start” the engine using an-

other source. Electricity fluctuations

can damage the ECU (Electronic Con-

trol Unit).

●

Always disconnect negative (-) battery

cable lead before charging battery, and

also unplug harness from ECU before

performing any welding on equipment.

Cleaning the Terminals

If battery terminals are corroded,

remove the

battery

from the mower. Using a wire brush,

remove corro sion with a solution of

one part bak-

ing soda and four parts water.

Rinse with clean

water. Coat the terminals with petroleum jelly or

terminal protector spray to retard further corrosion.