14

Fault Finding

Fault Finding

This section provides an easy reference guide to the more common problems that may occur during the

operation of your appliance. The fault finding guide in this section is intended to help you correct, or at

least accurately diagnose problems with your equipment.

Although this section covers the most common problems reported, you may encounter a problem not

covered in this section. In such instances, please contact your local authorised service agent who will

make every effort to help you identify and resolve the problem. Please note that the service agent will

require the following information:-

The Model Trade Name and the Serial Number of the Appliance. (both can be found on

the Technical Data Plate located on the appliance.

Fault

Possible Cause

Remedy

Insufficient heating of the

cooking zone.

Unsuitable pan material.

Use only approved pans.

Continuous heating of the

cooking zone at maximum

power.

Knob switch faulty.

Check / Replace the knob switch.

Call the service provider.

Empty cooking zone starts

operating.

Pan detection sensor faulty.

Replace / repair generator.

Call the service provider.

Small metal objects are heated. Pan detection sensor faulty.

Replace / repair generator.

Call the service provider.

Pan bottom diameter is less than

120 mm.

Use suitable pan size.

Generator defective.

Replace / repair generator.

Call the service provider.

Appliance not working.

Mains fuse or supply interrupted.

Check fuses / mains connection.

Fuses blow when switching ‘on’

appliance.

Short circuit in generator.

Replace / repair generator.

Call the service provider.

No heating of cooking zone.

Summary of Contents for IN8200E

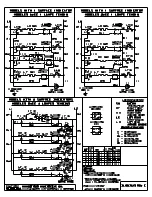

Page 8: ...6 Dimensions Dimensions IN L 8200E IN L 8400E...

Page 21: ......