GB

14

W 95

●

The spray movement should come from the arm, not just from the wrist. This

ensures that a uniform distance is maintained between the spray gun and the spray

surface during the spray operation (Illus. 4).

●

To achieve optimal spray results, spray back and forth over the surface (Illus. 5).

Cleaning and Maintenance

The spray gun can only operate satisfactorily if it is cleaned and preserved

after each use.

Attention!

Never immerse the spray gun in liquid when cleaning.

1 Empty out the remaining paint from the container.

2. Put proper thinner in the container and trigger the sprayer for approx. 2 seconds.

3. Pull the main plug out of the socket.

4. Disassemble the spray gun as shown in Illus. 8 (spare parts).

5. Thoroughly clean all soiled parts.

6. Reassemble the parts in reverse order.

7. Put a few drops of oil (e.g. sewing machine oil) in the intake and runback holes

(Illus. 6, arrow). Briefly switch on the spray gun.

Flexible Nozzle Extension (Illus. 7)

For spraying ceilings, resting objects or hard-to-reach areas e.g. radiators

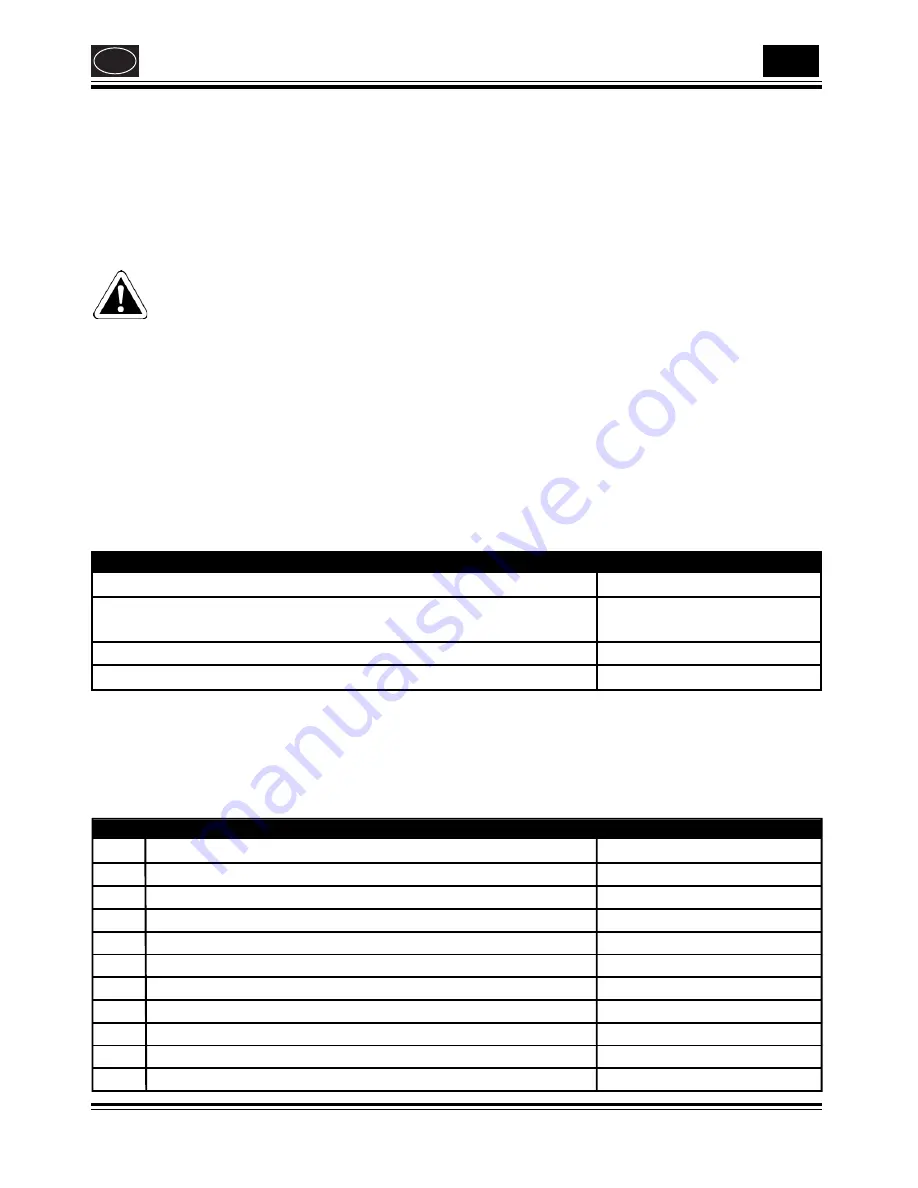

Accessories W 95

(not included in scope of delivery)

Designation

Order No.

Round spray nozzles for various spray materials:

Very thin spray materials/nozzle size: 0,5

0046 894

Paint container with cover

0414 906

Flexible nozzle extension with atomiser

0046 675

Spare Parts List W 95

Pos

Name

Order No.

1

Suction tube

0413 305

2

Paint container with cover

0414 906

3

Nozzle 0,8 mm

0046 903

4

Locking nut

0413 310

5

Valve

0209 042

6

Pump housing

0500 255

7

Piston spring

0033 028

8

Piston

0198 207

9

Nozzle spanner

0199 327

10

Viscosity measuring cup

0209 058

Summary of Contents for W 95

Page 1: ...W 95 D GB F NL 2 JAHRE GARANTIE 2 YEARS GUARANTEE 2 ANS DE GARANTIE ...

Page 2: ...1 0050342 3 4 5 0209058 2 ...

Page 3: ...3 6 7 ...

Page 4: ...8 ...