9

GA 2800EA, GA 2805EA

OPERATING MANUAL

EDITION 12/2008

PART NO. DOC350731

2.5.2

EXPLOSION PROTECTION IDENTIFICATION

2.5.3

MAXI. SURFACE TEMPERATURE

2.5.4

SAFETY INSTRUCTIONS

2.5

USE IN AN EXPLOSION HAZARD AREA

2.5.1

CORRECT USE

2.4

SAFETY-RELEVANT INFORMATION ABOUT DISCHARGES

The plastic parts of the spray gun are charged electrostatically by the high-voltage field

of the spray pistol. Harmless discharges (brush discharges) are possible after contact with

plastic parts. They are completely harmless for people.

The corona discharge at the electrode end is visible during darkness at a distance of be-

tween 4 and 10 mm; 0.15 and 0.4 inches, between the spray gun and spray object.

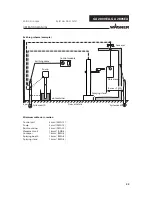

4HEELECTROSTATICSPRAYGUN'!%!AND'!%!ISSUITABLEFORSPRAYINGLIQUIDMATE

RIALSPARTICULARLYCOATINGMATERIALSUSINGTHEAIRATOMIZINGMETHOD

#OATINGMATERIALSCONTAININGSOLVENTSOF%XPLOSION#LASS))!MAYBEUSED4HESPRAYGUN

MAYONLYBEUSEDINCOMBINATIONWITHACONTROLUNIT%0'

!SDElNEDINTHE$IRECTIVE#%!4%8 THEUNITISSUITABLEFORUSEINAREASWHERE

THEREISANEXPLOSIONHAZARD

))'%%XM*4

#%

#OMMUNAUTÏS%UROPÏENNES

.OMINATEDTESTINGBODY04"

%X

3YMBOLFOREXPLOSIONPROTECTION

))

5NITCLASS))

#ATEGORY:ONE

'

%XATMOSPHEREGAS

%

%UROPEANSTANDARD

%X

%XPLOSIONPROTECTION

M* -AXIGNITIONENERGY

4

4EMPERATURECLASS

s

-AXSURFACETEMPERATURE

²#²&

s

0ERMISSIBLEMATERIALTEMPERATURE ²#²&

s

0ERMISSIBLEAMBIENTTEMPERATURE ²#²&

3AFEHANDLINGOF7!'.%2SPRAYUNITS

-ECHANICALSPARKSCANFORMIFTHEUNITCOMESINTOCONTACTWITHMETAL

)NANEXPLOSIVEATMOSPHERE

$ONOTKNOCKORPUSHTHEUNITAGAINSTSTEELORRUSTYIRON

$ONOTDROPTHEGUN

5SEONLYTOOLSTHATAREMADEOFAPERMITTEDMATERIAL