6

© Wagner Spray Tech. All rights reserved.

English

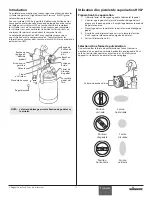

Replacing the air valve Seals

1. Remove the old rear air valve seal. It may stay on the end

of the needle guide shaft spring or in the material flow

adjustment housing.

2. Slide the new rear seal into the material adjustment housing.

3. Remove the front seal retaining clip using a snap-ring pliers.

4. Slide the old front air valve seal off of the needle guide shaft.

5. Place the new front air valve seal on the needle guide shaft

with the beveled side facing the gun.

NOTE: Make sure that the new front air valve seal looks like

the one that was just removed.

SIDE VIEW

Front Air Valve Seal

Beveled Side

6. Snap the front seal retaining clip onto the needle guide shaft.

Needle

Guide Shaft

Rear Air

Valve Seal

Spring

Material Flow Adjustment Housing

Front Air

Valve Seal

Front Seal Retaining Clip

Removing the Packing

1. Remove the packing nut using a 3⁄8 inch wrench.

2. Insert a long, narrow-bladed flathead screwdriver through the

back of the gun and into the packing hole.

3. Press the screwdriver firmly into the packing and turn

counterclockwise. This should back the old packing out of the

threaded hole. If it does not, push the screwdriver more firmly

into the packing and try again. If this still does not remove the

packing, use a pick tool to pull the packing out.

Packing Nut

Packing Hole

NOTE: Make sure all of the old packing is removed before

installing the new packing.

Installing the New Packing and Reassembling the Gun

1. Place the new packing into the packing hole.

2. Thread the packing nut one turn into the packing hole. Do

not tighten.

3. Push the needle guide shaft through the back of the gun body

and thread on the retaining nut.

4. Grasp the material flow adjustment housing with the needle

attached. Slide the needle with the spring and the rear

air valve seal through the needle guide shaft and into the

packing nut. Tighten the material flow adjustment housing

securely using a wrench.

5. Tighten the packing nut securely using a 3/8 inch wrench,

then loosen the packing nut a quarter turn.

6. Assemble the trigger by inserting the retaining pin or pins and

attaching the snap rings.

7. Pull the trigger to make certain the needle moves freely. If

the needle sticks, loosen the packing nut. If the packing leaks,

tighten the packing nut.

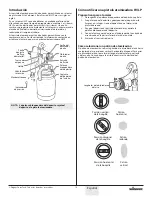

Replacing the Check valve, valve Seal, and air Tubes

The check valve is a one-way valve designed to allow air into the

cup, pressurizing the cup’s contents. Because it is a one-way valve, it

prevents paint from seeping up the air tube into the air passages of

the gun. It also eliminates any delay in material flow when the gun is

triggered by maintaining pressure in the cup.

The check valve rotates open easily for cleaning. It contains a valve

seal that can be removed and cleaned with soap and water for

waterborne materials or a compatible solvent for other materials. To

replace the check valve, the valve seal, and/or the air tubes:

1. Pull the lower air tube from the bottom of the check valve.

2. Pull the check valve from the upper air tube.

3. Unscrew the two halves of the check valve.

4. Remove the worn valve seal.

5. Clean the check valve body with a solvent appropriate to the

type of material being used.

NOTE: Thoroughly clean the inside of the top half of the

check valve but do not scratch it.

6. Insert a new valve seal, stem up, into the top of the check

valve as shown.

7. Tighten the two halves of the check valve together.

8. Insert the top of the check valve into the upper air tube.

NOTE: Insert the check valve into the air tube so that the

arrow on the valve points toward the gun.

GUN

Check Valve

Air Tube

Air Tube

Valve Seal

9. If the lower air tube is too long, trim the tube so that it fits the

gun.

10. Push the lower air tube onto the bottom of the check valve.

NOTE: Make sure to attach the shorter air tube to the gun

fitting and the longer air tube to the cup lid air

nipple.