6

EN-XXX_ECOplus-Solar-Storage_MA-201026-1WA10603

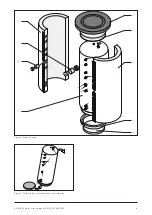

Figure 8 Installation of a CORREX® impressed current anode

3.7 Install a Impressed Current Anode

The installed sacrificial anode can be replaced with a

maintenance free impressed current anode (optional ac-

cessory, fig 8)

●

Remove cable and existing magnesium anode (1), (2)

●

Screw impressed current anode and fasten the cable to

the electronics device (3) - (5)

●

After filling the storage tank check function (see chap

„Maintenance“)

4 Startup of the System

4.1 Acceptance Protocol

The correct startup of the system must be certified by a

qualified person in the Final Check Protocol in order ren-

der the warranty agreement valid

4.2 System Check

After fitting all components, please carry out the following

checks:

●

Are all components fitted correctly?

●

Are all safety units installed? Is the 10 bar safety valve

fitted? If necessary, is a pressure regulator fitted and

can it be closed off from the vessel?

●

Are all fittings and connections safe and tight?

●

If present – were all electrical connections made to re-

quired standards?

●

Are the temperature sensors in the correct positions?

Do all controllers display plausible values?

4.3 Flushing the Installation

Malfunction or damage when storage tank is not ade-

quately purged!

In spite of careful production methods, some residues of

the processes, including metal slack, may remain inside

the pipes, the vessel and the heat exchangers These can

cause problems during operation of the system and may

lead to damage Therefore, the system must be flushed

before permanent operation starts Also filtering/retain-

ing devices should be installed at convenient points in

the system, as even later some production residues may

become dislodged and may have to be removed

4.4 Settings at Boiler and Solar

Controllers

The temperature limitation of 95 °C for the solar storage

vessel must never be exceeded.

Observe correct settings at boiler and solar controllers

(e g max boiler temperature)

4.5 Filling, Venting, Pressure Check

●

Pease make sure that before filling and startup of the

system, all openings are closed

●

(Fig 9) To fill the storage, open the cock of the safety

group in the cold water supply leg (17) and a water tap

of the connected supply While doing so, allow air to

escape through the bleed (9)

●

After venting the piping close all water taps If water

escapes from the air bleed, close it as well

●

Carry out a pressure test after the system has been

completely installed (max 10 bar) While test pressur-

izing, check all fittings and connections for leaks If nec-

essary retighten

1

2

3

4

5