Subject to modifications, errors excepted · © Wagner Solar Inc., 2011 · 485 Massachusetts Ave, Suite300, Cmbridge, MA 02139

40

%

TollFree: 877-97Wagner (877-979-2463)

8 Troubleshooting

Despite careful manufacture and installation defects may

occur in your SECUSOL system. Some common faults and

solutions for a professional installer are described below.

All maintenance and repair work (here in the columns

„Solution“) must be carried out by a trained professional.

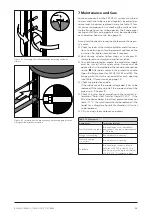

Table 15 Fault

Explanation

Solution

DHW section

1. DHW connections are leaking

1.1 Settling of gaskets when

connections were not sufficiently

tightened.

Re-tighten connections

Solar circuit

1. Collectors are not filled.

1.1 Length of collector loop beyond

limitations of use?

Table 1 shows the length limits for the collector loop. The

maximum length may have been exceeded.

1.2 Incorrect filling capacity?

Empty the system and refill as specified.

3. Cavitation noise

1

3.1 Incorrect filling capacity?

Cavitation noises may occur if the filling quantity is too low.

Empty the system and refill as specified.

3.2 Negative pressure in the system?

Negative pressure is possible if the system is opened for a

short time during operation or if solar fluid is let off via the

safety valve. Switch off system (controller), cool down solar

circuit to < 68 °F / 20 °C. Open filling tap at the solar flow

pipe to equalize the pressure and close filling tap again.

4. Safety valve in the solar circuit

blows off.

4.1 Incorrect filling quantity?

The filling quantity of the solar fluid may have been

incorrectly measured. Switch off system (controller, manual

operation: pump OFF) until it has cooled down. If

necessary draw off hot water until the tank sensor shows

< 68 °F / 20 °C. Then open filling and emptying tap on the

solar flow pipe and collect fluid in a container. Close filling

and emptying tap.

4.2 Length of solar circuit outside min./

max. limitations?

Table 1 shows the length limits for the solar circuit. The

minimum length may have been undercut and solar fluid

was blown off the safety valve. After equalizing the

pressure (proceed as per 3.2) the system is operational

again.

5. Pump is in idle state but

collector loop does not empty.

5.1 Have the collector loop pipes not

been installed at a steady down

grade slope?

No further measures required. During strong solar

radiation and idle pump, the collectors will empty by

themselves as a result of momentary vapor formation.

6. The Storage cylinder insulation

is moist at the bottom

6.1 Are all pipe connections and

flange/socket properly tightened?

Flat sealing gaskets tend to settle during the first weeks of

operation, therefore all connections should be re-

tightened after a few weeks..

6.2 Safety valve blow off

Additional fault analysis acc. to 4.2

After the fault was removed, the insulation will dry off from

the heat supplied by the heated storage cylinder. No

further steps need to be taken.

1) For smooth operation the circulator pump used in the system requires a minimum liquid column on the suction side (i.e. towards the

storage cylinder). If the column height drops below the required minimum cavitation can occur, which is spontaneous vaporization of

small amounts of liquid that can cause mechanical damage to the pump impeller. Additionally underscoring the gas solubility limit air

bubbles may form around the impeller, possibly diminishing the pump‘s capacity. Cavitations can be easily detected acoustically

because of noticeable flow noise during operation and a significant drop in capacity.

In order to avoid cavitation, the specified filling volume of the system has to be precisely adhered to. Furthermore the build-up of

overpressure is neccessary when the solar liquid heats up, for which the system has to be airtight at all times.