2

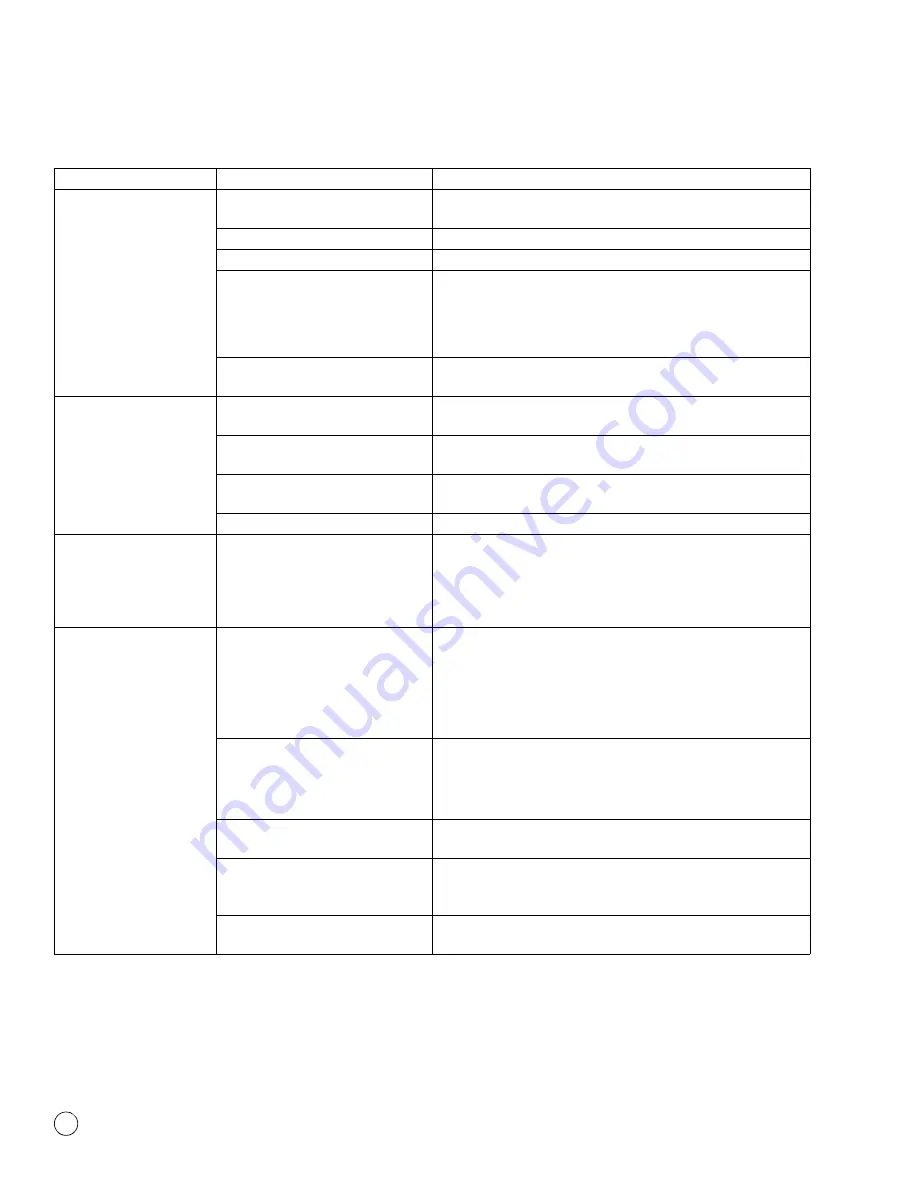

Troubleshooting

6

WABCO

Maintenance Manual 31 (Revised 08-18)

Compressor leaks engine

coolant

Loose fitting

Check fittings at compressor and engine for leaks and verify fittings

are correctly torqued.

Cracked coolant port

Replace cylinder head.

Porosity in cylinder head

Replace cylinder head.

Leaking of gasket internal to the

cylinder head

Verify cylinder head bolts are correctly torqued. Make necessary

adjustments.

Inspect gasket for cracks or signs of wear. Replace if necessary.

Replace cylinder head.

None of the above, but condition

persists

Replace compressor.

Compressor pressurizes

coolant system or coolant

leakage to compressor

inlet

Leaking of gasket internal to the

cylinder head

Inspect gasket. Replace if necessary.

Cavitation or corrosion in cylinder

head

Replace cylinder head.

Porosity in cylinder head or cylinder

head cracked

Replace cylinder head.

None of above, but condition persists

Replace the compressor.

Unloader leakage

Possible internal damage, including

worn or damaged unloader piston

O-ring, porosity in unloader piston

bore, loose or leaking seal at unloader

piston bore

Replace compressor cylinder head assembly.

Compressor head gasket

failure

Discharge line blocked due to freezing

or carbon build-up

Check for trap (low spots) in lines.

Make necessary repairs.

Clear discharge line. Replace line if necessary.

Check for carbon build-up. If carbon build-up is present, replace the

discharge line.

Frozen or blocked line to governor

Clear blocked line. Replace line if necessary.

Check for air dryer malfunction. Repair or replace as required. Refer

to the air dryer manufacturer’s maintenance manual for service

information.

Governor malfunction

Repair or replace the governor. Refer to governor manufacturer’s

maintenance manual for service information.

Incorrect cylinder head bolt torque,

machining defect on cylinder head or

block, defective cylinder head gasket

Inspect gasket. Replace if necessary. Verify all bolts are correctly

torqued. If problem persists, replace cylinder head.

None of the above, but condition

persists

Replace compressor cylinder head assembly.

Condition

Possible Cause

Solution

Table A: Compressor Troubleshooting Guide

Summary of Contents for System Saver 318

Page 4: ...Notes...