Group

28

fgnition

systems

Design

and function - System

descriptions

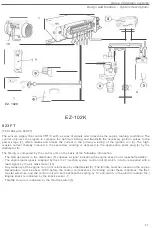

EZ-115K

EZ-115K

B280EIF

The

co

ntrol unit

(1) computes the optimum timing on

the

basis of information

from the

various sensors

and delivers

an ignition pulse at exactly the

cor

rect

ins

tant to the

power stage

which responds by making and breaking the

current

in the

primary winding of the ignition coil

(25).

The high-tension

cu

rrent

induced

in the

secondary winding by

interruption of the primary current is

fed

to

th

e

distribut

or (28)

for

delivery

to

the appropriate spark plug (29).

The

con

trol

unit computes the timing on

the

basis of the following information:

-

Engine

speed

and

crankshaft position signals are supplied by the speed

/

positi

o

n

pick-up

(2)

.

-

Engine

knock

detected by the

knock

sensors

(7)

.

-

Ignition in NO

.

1

cylinder is indicated by the No.1 cylinder detector (15)

.

-

Engine

load signals are

supplied

by

the

fuel injection system

control

unit (19).

-

Eng

i

ne

temperature

is

indicated by

th

e

t

empera

ture

sensor

(23)

.

-

Closure of the

throttle

is

ind

icated by

the throttle

switch

(2

4

)

.

The

ignition

pulse

is interrupted by

the contro

l

unit

at a speed of

approx. 6300

r/min.

Th

e

control unit

can

vary the timing from

approx.

60

°

before TDC to approx. "

.

after

TD

C.

55