35

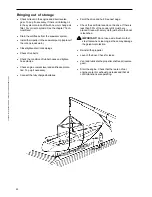

Fuel pre-filter. Draining and replacing

filter insert

Draining

The fuel pre-filter is an optional extra.

Position a container under the fuel filter. Drain off

water and contaminants using the cock/plug at the

bottom of the glass.

IMPORTANT! Wait a few hours after the engine

has been turned off before draining the filter.

Replacing filter insert

Close fuel cock at the fuel tank. Position a container

under the fuel filter.

Remove the glass bowl by slackening off screw (1).

Empty and clean glass. Replace insert and reinstall

glass. Open fuel cock. Vent fuel system. Deposit the

old filter insert at a properly designated disposal

site.

Start the engine and check for leaks.

WARNING! Approaching or working on a running

engine is dangerous. Watch out for rotating

components and hot surfaces.

Fuel filter. Changing

Clean the filter mounting. To avoid fuel spills put a

plastic bag over the filter before it is unscrewed.

Unscrew the filter. Moisten the filter rubber gasket

with a little oil. Screw on the new filter by hand until it

is in contact with the mating surface. And then a

further half turn but no more! Vent fuel system.

Deposit the old filter at a properly designated

disposal site.

Start the engine and check for leaks.

WARNING! Approaching or working on a running

engine is dangerous. Watch out for rotating

components and hot surfaces.

1

7741986 - Downloaded from www.volvopenta.com 06/10/2006 13:10:27