Maintenance

Doing Your Own Maintenance and

Repairs

The following sections provide basic periodic maintenance procedures. Repair and advanced maintenance pro-

cedures are covered in the

Do it Yourself

manual. If you intend to carry out any maintenance on your equipment,

we urge you to be thoroughly familiar with the procedures described in this manual.

Always read and follow the

safety warnings provided in this manual.

If you are uncertain about any procedures described in the manual or you would like to purchase a workshop or

Do it Yourself

manual, please contact your Volvo Penta dealer or visit Volvo Penta on the Internet. Keep in mind,

however, that there are certain tasks which should only be performed by your Volvo Penta dealer. The dealer

has the tools, expertise, and most current information needed to properly perform these tasks.

Never carry out

any work on the engine if you are unsure of how it should be done. Instead, contact your Volvo Penta

dealer for help.

Replacement Parts

Always insist that your dealer use genuine Volvo Penta parts, oils, and lubricants when servicing your engine

and power package. Genuine Volvo Penta parts have been designed and approved to meet the safety require-

ments and heavy demands of marine engines. Volvo Penta replacement parts are designed to meet all applicable

legal requirements and industry standards for marine applications.

WARNING!

Do not use automotive or other non-marine parts on your Volvo Penta engine. Non-marine electrical and fuel

parts do not meet USCG and other requirements for explosion prevention in gasoline fueled boats. Use of non-

marine parts may result in onboard explosions.

In your Volvo Penta product, certain fuel and electrical system components have been designed to comply with

U.S. Coast Guard and other regulations for explosion prevention. Parts or components that comply with these

regulations are designed so they will not emit fuel vapors or cause ignition of fuel vapors in the engine compart-

ment. To prevent explosion or fire, do not substitute automotive or general hardware parts for the following:

●

Circuit breakers, alternator, and related wiring.

●

Starter and related wiring.

●

Distributor, distributor cap, spark plugs, high tension leads (spark plug wires), and related igni-

tion parts.

●

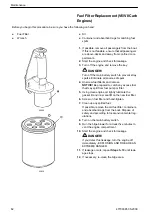

Fuel pumps, relays, filter, and related parts.

●

Fuel injector O-rings, injector fuel line pressure relief valve and caps, fuel reservoir vent hose and

cover gasket, high pressure fuel pump mounting O-rings, fuel pressure regulator, and fuel rails.

NOTICE!

Do not use automotive or other non-marine parts on your Volvo Penta engine. Non-marine parts may

not be designed for the high loads, harsh environment, and durability requirements of a marine engine. Non-

marine parts may fail prematurely, disabling the engine. Engine or power package failure caused by the use of

non-marine parts is not covered by warranty.

Substituting automotive or generally supplied parts and hardware may result in product malfunction. Never use

parts of unknown quality. See your Volvo Penta dealer for replacement parts. You can depend on your dealer to

furnish expert service and genuine Volvo Penta parts.

Volvo Penta engine oils and transmission lubricants are formulated with the correct lubrication qualities and

corrosion inhibitors needed for marine applications. Use of these oils and lubricants ensures proper operation

and protection of your engine and sterndrive. See your Volvo Penta dealer for genuine oils and lubricants.

47700385 05-2009

75

Summary of Contents for 3.0GLP-J

Page 1: ...OPERATOR S MANUAL 3 0L 4 3L 5 0L 5 7L 8 1L SX A DPS A ...

Page 124: ......

Page 128: ......

Page 129: ......