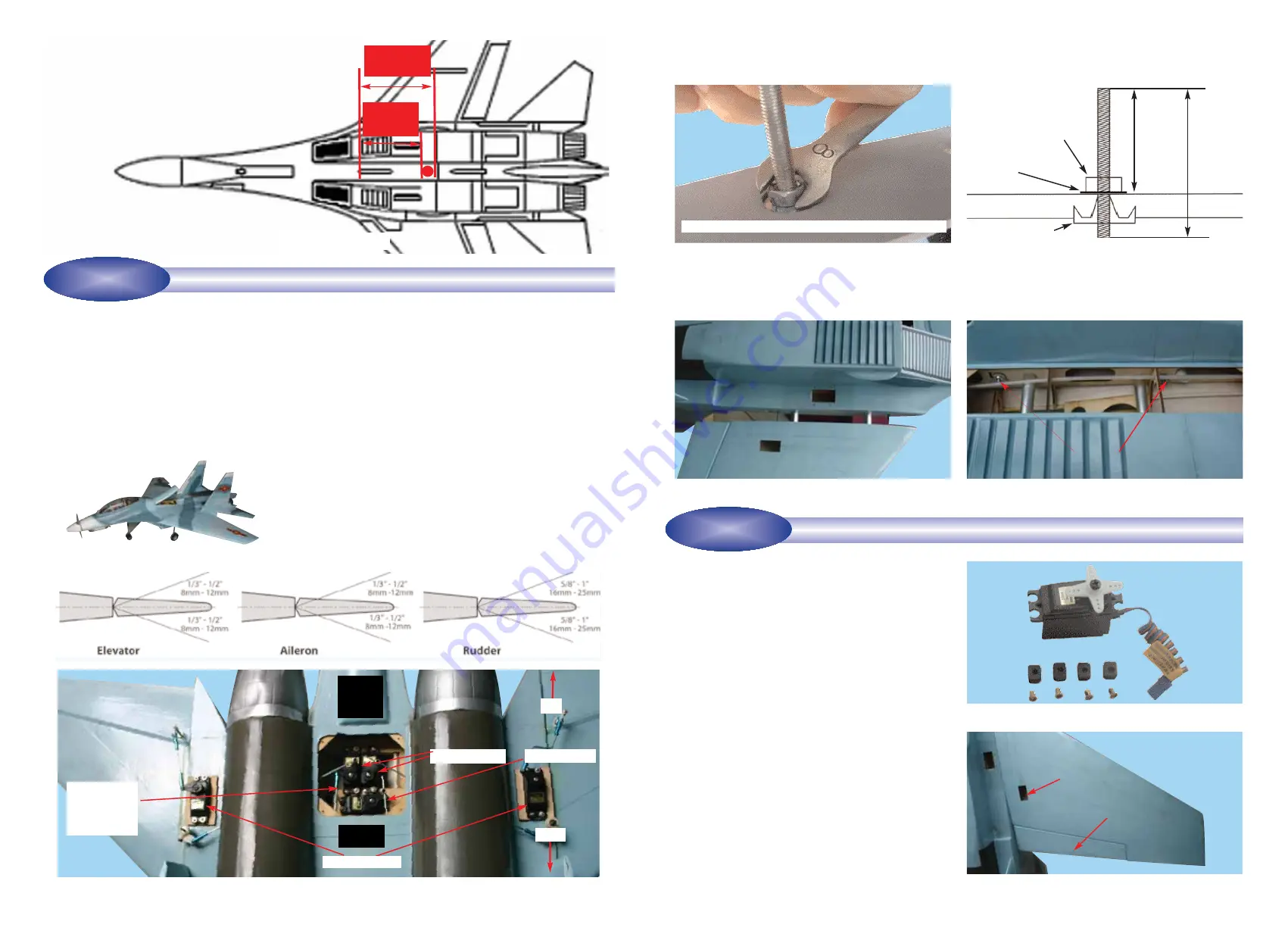

2B - Aileron servo location

3

Step 1.8

While holding the aluminum tubes centered in the

fuselage, carefully slide each wing half onto the tubes and

flush the wing root against the side of the fuselage. See 1J

Step 1.9

Place flat washers over the wing bolts and then

install the butterfly nuts. Do NOT overtighten. For double

security also install the lock nuts. See 1K

1H - Hold the wing bolt while tightening the lock nut

1J - Plug the wing panels into the fuselage

1K - Tighten the wing nuts. DO NOT OVERTIGHTEN. For

double security also install the lock nuts

1I - Typical installation of wing bolts into the wing

Step 1.7

Secure the wing bolt to the wing by tightening the

lock nut. See 1H

Illustration 1I:

Typical installation of the wing bolts into the

pre-installed blind nuts located inside the wing so that 3 in.

(75 mm) of each wing bolt protrudes from the wing root.

4 mm nut

Washer

3-3/4 in.

(95 mm)

4-3/4 in.

(120 mm)

Wing root

Wing nut

4 mm blind nut

Aileron servo cavity

2A - Prepare the servos by fitting the rubber grommets &

ferrules supplied with your servos

To install the aileron servos into the wing you will need the

following items:

- Servos

- Servo mounting screws and grommets as supplied with

servos

- Servo control arms as supplied with servos

- Two aileron control rod assemblies supplied with the kit

The assemblies consist of a metal rod with a clevis on

each end

- Low tack masking tape

- 2 aileron control horn assemblies

Step 2.1

Turn the wings upside down and locate the aileron

servo cavities. See 2B

Step 2.2

Trial fit the aileron servo into the servo mounting

cavity. You may have to modify the cavity slightly to provide

clearance for the servo and servo wires. Use a hobby knife

to modify the cavity as required. Most servos have their out-

put shaft closer to one end than the other. We recommend

locating the servo so that the output shaft is as close to the

rear of the wing as possible.

Aileron

INSTALLING THE AILERON SERVOS INTO THE WING

STAGE 2

14

CONTROL SURFACE THROW SPECIFICATIONS

:

The throws are measured at the widest part of the control

surface. Adjust the position of the pushrods at the control

and/or servo horns to control the amount of throw. You may

also use ATV's if your radio has them but the mechanical

linkages should still be set so that the ATV's are near 100%

for best servo resolution.

Low rate

High rate

ELEVATOR

1/3 in (8mm)

up

1/2 in (12 mm)

up

1/3 in (8mm)

down

1/2 in (12 mm)

down

AILERON

1/3 in (8 mm) up

1/2 in (12 mm)

up

1/3 in (8 mm) down

1/2 in (12 mm)

down

RUDDER

5/8 in (16 mm) right

1 in (25 mm)

right

5/8 in (16 mm) left

1 in (25 mm)

left

CAUTION: Tighten snugly but DO NOT OVERTIGHTEN

CONFIRM MECHANICAL INTEGRITY

STAGE 27

5-1/8 in

(130mm)

4-1/2 in

(120mm)

27A - TYPICAL ARRANGEMENT OF RECEIVER, RECEIVER BATTERY, SERVOS AND PUSH RODS

Rudder servos

Receiver

battery

Nose steering

push rod con-

nected to the

rudder servo

Throttle servo

Receiver

Elevator servos

26A - CG location

Tail

Nose

Step 27.1

Once you have confirmed that the CG is correct, you should do a thorough review of the entire model before

your first flight. Check everything twice! Every hook up, every coupling, everything! Do it twice!!

Step 27.2

Before your first flight, have an experienced flyer review your work. Do not fly your model until it has been

checked out by a third party who knows how to fly and how to set up a model aircraft. Do not fly alone. Seek experi-

enced help.

Step 27.3

Once you have completed your first flight, get in the habit of checking your model over before and after each flight!

Don’t fly if you find something that is not right!