Operating manual Omni-Flow

Edition 1.0. 09/2017

17 / 32

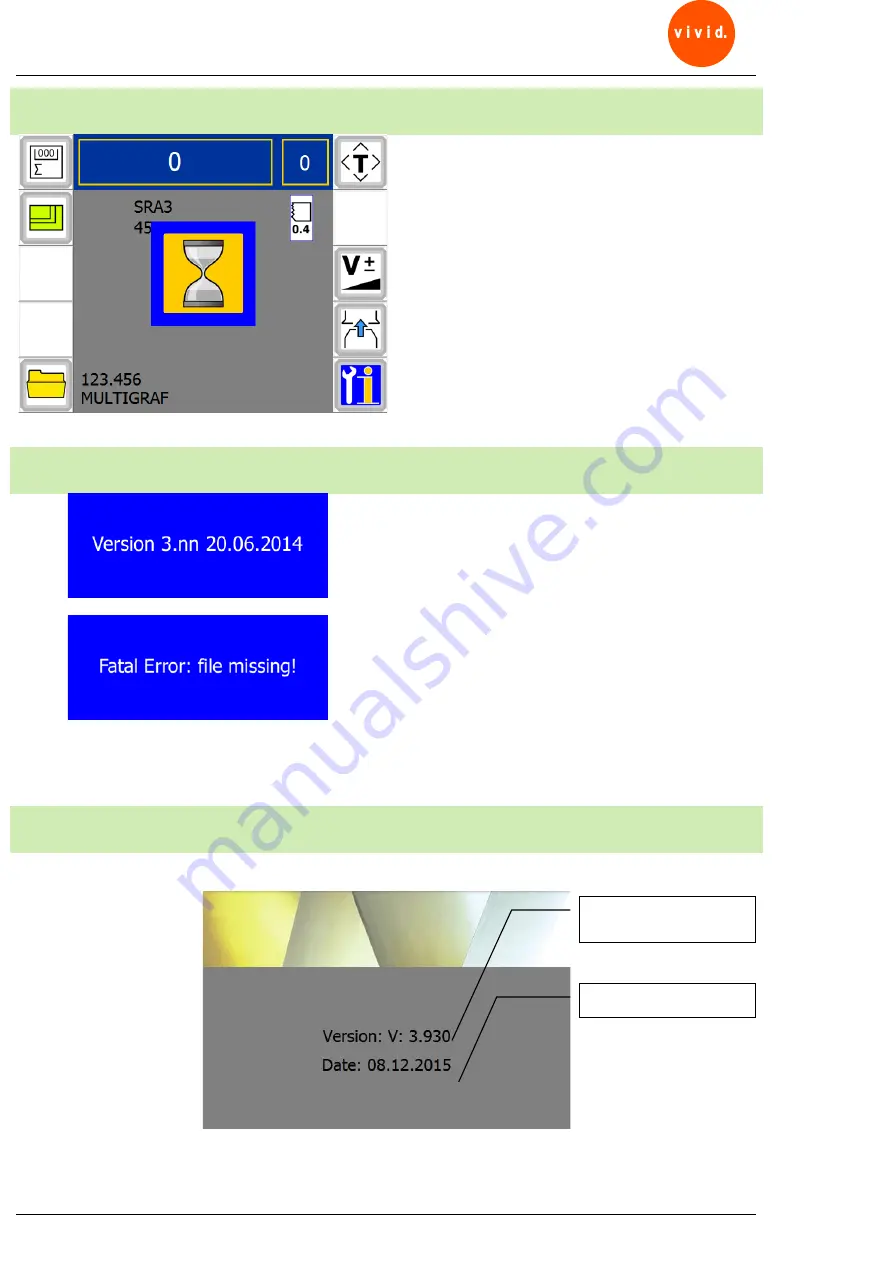

Display busy!

The busy symbol is displayed for functions for which

a certain state or position must be waited for.

During this display (hourglass in the middle of the

screen) the display keypad is locked.

Starting the display

During booting, version number and date of creation

are displayed.

If the program data is not available or corrupt, this er-

ror message is displayed.

(Service hotline report)

When booting the display, those job and parameter

values are loaded which were active when the display

was last switched off.

Start screen

During detection and ini-

tializing of the peripheral

equipment the start

screen is displayed.

Software version and

date of creation

Machine type

Type: Omni-Flow