Potential differences can occur between different sections when con-

trollers and peripheral equipment are connected by means of non-iso-

lated connections or the screens of screened cables are connected at

both ends and grounded on different sections of the plant. One

reason for a potential difference can be that different sections of the

plant are powered from different power sources. These potential dif-

ferences must be reduced by means of equipotential bonding conduc-

tors to ensure that the electronic equipment employed on the plant

operates properly.

n

The lower the impedance of the equipotential bonding conductor,

the higher the effectiveness of potential equalization.

n

The impedance of the equipotential bonding conductor must not

exceed 10% of the impedance of the screen where screened

signal lines are connected between the different sections of the

plant and the screening is connected to ground/neutral on both

sides.

n

The cross-sectional area of the equipotential bonding conductor

must be calculated to carry the maximum equalization current.

The following cross-sections have been successfully employed:

– 16mm

2

Cu for equipotential bonding conductors up to 200m

– 25mm

2

Cu equipotential bonding conductors exceeding 200m.

n

Use copper or galvanized steel for equipotential bonding conduc-

tors. These must be connected to ground/neutral by means of

large-surface connections that are protected from corrosion.

n

The equipotential bonding conductor should be installed in such a

manner that it includes the smallest surface between the bonding

conductor and the signal lines.

Screening is one method commonly used to reduce (attenuate) the

interference pick-up from magnetic, electrical or electromagnetic

fields.

n

Interference on screens is conducted to ground by the conductive

connection between the screen and the screening rain/enclosure.

To avoid interference from these currents it is very important that

the neutral connection is a low-impedance connection.

n

You should only use cables that are provided with a braided

screen. The degree of screening should be more than 80%.

n

Avoid cables with foil-type screens as the foil can be easily dam-

aged by tension and pressure at the point of attachment; this can

result in reduced effectiveness of the screening action.

n

As a rule you should always ground the screens of cables on both

ends. This is the only way in which you can ensure that high fre-

quency interference is attenuated properly.

In exceptional cases it may be necessary to ground the screen on

one side only. However, this will only attenuate the lowest frequen-

cies. The one-sided grounding of screens may provide advantages

when:

n

It is not possible to install an equipotential bonding conductor

n

Analogue signals (a few mV or mA) must be transmitted

n

Foil-type screening (static screening) is employed.

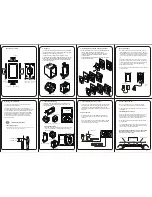

Equipotential bonding

Rules for equipotential

bonding

Screening of lines and

cables

One-sided grounding of

screens

VIPA HMI Touch Panel

Installation Guidelines

EMC-equitable cabling

HB160 | TP-ECO | 62K-NHC0 | GB | 14-27

72